Algal protein gives boost to electrochemical water splitting

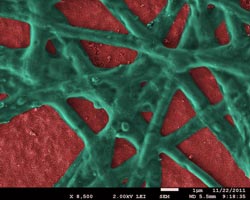

Hematite nanoparticle film (red) with functional phycocyanin network (green) attached. (Image by Dr. E. Vitol, Argonne National Laboratory)<br>

Water splitting in photo-electrochemical cells to yield hydrogen is a promising way to sustainable fuels. A team of Swiss and US scientists now made major progress in developing highly efficient electrodes – made of an algal protein, thus mimicking a central step in natural photosynthesis.

Photosynthesis is considered the «Holy Grail» in the field of sustainable energy generation because it directly converts solar energy into storable fuel using nothing but water and carbon dioxide (CO2). Scientists have long tried to mimic the underlying natural processes and to optimize them for energy device applications such as photo-electrochemical cells (PEC), which use sunlight to electrochemically split water – and thus directly generate hydrogen, cutting short the more conventional approach using photovoltaic cells for the electrolysis of water.

Traditionally, PEC electrodes are made of semiconducting materials such as metal oxides, some of which are also known for their photocatalytic properties. For quite some time, researchers at Empa’s Laboratory for High Performance Ceramics (LHPC) have been investigating nanoparticles of these materials, for instance titanium dioxide (TiO2), for the neutralization of organic pollutants in air and water. Collaborating with colleagues at the University of Basel and at Argonne National Laboratory in the US, they now succeeded in making a nano-bio PEC electrode, consisting of iron oxide conjugated with a protein from blue-green algae (also known as cyanobacteria), which is twice as efficient in water splitting as iron oxide alone.

Inspired by photosynthesis

Iron oxide, in particular hematite (alpha-Fe2O3), is a promising electrode material for PEC because it is susceptible to visible wavelengths and thus uses sunlight more efficiently than photocatalysts like TiO2, which can only use the UV part of solar radiation. What’s more, hematite is a low-cost and abundant material.

The second ingredient in the novel electrode «recipe» is phycocyanin, a protein from blue-green algae. «I was inspired by the natural photosynthetic machinery of cyanobacteria where phycocyanin acts as a major light-harvesting component. I wanted to make artificial photosynthesis using ceramics and proteins», recalls Debajeet K. Bora who designed the new electrode during his PhD thesis at Empa. «The concept of hematite surface functionalization with proteins was completely novel in PEC research.»

After Bora covalently cross-coupled phycocyanin to hematite nanoparticles that had been immobilized as a thin film, the conjugated hematite absorbed many more photons than without the algal protein. In fact, the induced photocurrent of the hybrid electrode was doubled compared to a «normal» iron oxide electrode.

One tough cookie

Somewhat surprisingly, the light harvesting protein complex does not get destroyed while in contact with a photocatalyst in an alkaline environment under strong illumination. Chemists would have predicted the complete denaturation of biomolecules under such corrosive and aggressive conditions. «Photocatalysts are designed to destroy organic pollutants, which are a burden to the environment. But here we have a different situation», says Artur Braun, group leader at Empa’s LHPC and principal investigator of the study. «There seems to be a delicate balance where organic molecules not only survive harsh photocatalytic conditions, but even convey an additional benefit to ceramic photocatalysts: They double the photocurrent. This is a big step forward».

The project was fully funded by the Swiss Federal Office of Energy (SFOE). Bora who will soon have completed his PhD thesis says he will continue what he started at Empa during a postdoc at the University of California, Berkeley, which he will assume early next year.

Media Contact

More Information:

http://www.empa.chAll latest news from the category: Power and Electrical Engineering

This topic covers issues related to energy generation, conversion, transportation and consumption and how the industry is addressing the challenge of energy efficiency in general.

innovations-report provides in-depth and informative reports and articles on subjects ranging from wind energy, fuel cell technology, solar energy, geothermal energy, petroleum, gas, nuclear engineering, alternative energy and energy efficiency to fusion, hydrogen and superconductor technologies.

Newest articles

New insights into the mechanisms of chromosome segregation errors

Research on centromere structure… Researchers from the Kops group in collaboration with researchers from the University of Edinburgh, made a surprising new discovery in the structure of the centromere, a structure…

“Topological hall effect” in two-dimensional quantum magnets

In a recent study published in Nature Physics, researchers from the Hefei Institutes of Physical Science of the Chinese Academy of Sciences, together with researchers of University of Science and Technology of China, have introduced the…

Coating Technologies of the Future

LZH and Cutting Edge Coatings at Optatec… At Optatec 2024, the Laser Zentrum Hannover e.V. (LZH) and Cutting Edge Coatings GmbH (CEC) present new opportunities in coating technologies for the…