Engineers to Create Parts of Virtual Crash Test Dummy

You really can learn a lot from a dummy.

For decades, automakers have been crashing test dummies to gain insight to how various auto safety systems protect – or fail to protect – people during car accidents. But those dummies are made of plastic and steel, not tissue and bone. They can teach only so much.

A new generation of dummies will tell a lot more. An international group of automakers and suppliers has formed a Global Human Body Models Consortium to fund the best minds to build a better dummy.

Two teams of engineers with the University of Virginia's Center for Biomechanics will play major roles in the creation of this new “virtual” dummy, one that will live entirely within computers, but will be more realistic than any physical dummy ever subjected to a crash test.

These will be highly detailed computer dummies – computational models of a full human being – including extreme lifelike detail of the complexities and characteristics of flesh, bones, ligaments, blood vessels and organs.

“Already, cars and their safety systems are designed on computers,” said Richard Kent, one of U.Va.'s team leaders on the project and a professor of mechanical and aerospace engineering. “It's logical that we would create a virtual crash test dummy that would allow us to test these safety systems before they are ever physically built.”

Kent and his six-member team is charged with creating a highly detailed and realistic computer model of the human thorax and upper extremities, including the ribcage, muscles and ligaments, and the lungs and heart.

Jeff Crandall, a professor of mechanical and aerospace engineering and director of U.Va.'s Center for Applied Biomechanics, is leading another team in the development of a virtual pelvis and lower extremities. The Global Human Body Models Consortium recently awarded the two teams $3 million to complete their projects within the next few years.

Teams of researchers at six other universities and institutes are creating models of other parts of the human body, including the head, neck and abdomen.

“Eventually all of these models will be joined together to create the most sophisticated and lifelike simulation of the entire human body ever assembled for safety testing,” said Damien Subit, a U.Va. research scientist working on the model of the thorax.

He said the virtual human will be subjected to nearly infinite virtual crash scenarios to determine in graphic detail what happens to organs, bone and tissue when subjected to forces and impacts from a range of angles at different velocities. Researchers will be able to see, in effect, how a neck breaks in a crash, how a lung is punctured by a broken rib or a liver is bruised or a hip shattered.

“We are creating models, based on the actual anatomic details of the human body, that will respond to stress and strain and impact in the same way the actual human body does, so we can see precisely how injuries occur,” Kent said. “The ultimate result will be cars with far better safety systems, minimizing the severity of injuries and the frequency of fatalities.”

The advantages of a virtual dummy, compared to the typical physical crash test dummy, are huge. Currently, a typical crash test costs about $5,000 to $100,000. A virtual crash will cost nearly nothing – once the dummy is developed. And a regular physical dummy, with a life span of about 10 years, must be repaired after each crash. A virtual dummy will be, in a sense, immortal, and could be used repeatedly in a far wider range of crash scenarios.

Current physical dummies are built in only three height and weight models, representing an approximation of the many sizes of humans. The virtual dummy eventually will be configured in variable sizes and weights, representing the true range of human body types.

“This will be an adaptable, cost-saving system that will provide amazing insight to body injuries for improving auto safety,” Kent said.

He added that the virtual dummy could be useful in other ways as well, such as for the design of safer sporting goods, and in medical schools for students studying trauma injuries.

Contacts: Richard Kent, U.Va. researcher

434-296-7288, ext. 133

rwk3c@virginia.edu

Media Contact

More Information:

http://www.virginia.eduAll latest news from the category: Automotive Engineering

Automotive Engineering highlights issues related to automobile manufacturing – including vehicle parts and accessories – and the environmental impact and safety of automotive products, production facilities and manufacturing processes.

innovations-report offers stimulating reports and articles on a variety of topics ranging from automobile fuel cells, hybrid technologies, energy saving vehicles and carbon particle filters to engine and brake technologies, driving safety and assistance systems.

Newest articles

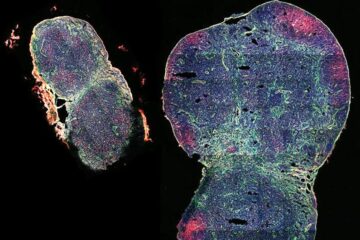

Expanding a lymph node, boosting a vaccine

A biomaterial vaccine enhances and sustains lymph node expansion following vaccination, boosting anti-tumor immunity in an animal model. Each one of us has around 600 lymph nodes (LNs) – small,…

AI to Make Crop Production More Sustainable

Drones monitoring fields for weeds and robots targeting and treating crop diseases may sound like science fiction but is actually happening already, at least on some experimental farms. Researchers from…

Cruise Ship as Data Collector

New Approaches in Ocean Observation… Scientific research – not only confined to dedicated research vessels but also from non-scientific vessels and marine infrastructures. This is one of the ideas promoted…