Smart Alloys – new research group at the Max-Planck-Institut Düsseldorf

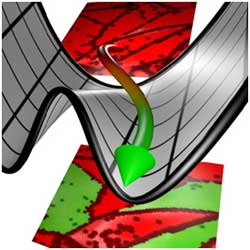

Logo of the group showing the intimate coupling between experiment and theory: The red fields show EBSD images of a material before and after phase transformation. The black/grey surface shows the energy dependence of a stable and unstable phase.<br>

The group is funded by a European Research Council Advanced Grant, awarded in January 2012 to Prof. Dierk Raabe and Prof. Jörg Neugebauer, both directors at the MPIE.

The new research group is introducing an innovative concept into the world of alloy design combining theory and experiment. The aim is the development of new superior materials with smart microstructures capable of adapting to external environmental changes.

The group is run by two scientists: Dr. Blazej Grabowski, theoretical physicist, and Dr. Cem Tasan, materials scientist. This rather unconventional formation is attributed to the high complexity of the enterprise and to the employed alloy design ideas. One of the design strategies is to introduce nanosized metastable particles into the microstructure of the new alloys.

The meta-stability is a challenging but crucial requirement allowing the nanoparticles to transform quickly under applied stress. This phase transformation can strengthen the material, or create a self-healing effect. “Imagine a crack which has just nucleated in the material”, says Grabowski. “As soon as the crack tip reaches one of the metastable particles, the stress induced by the crack tip forces the phase of the particle to transform. The accompanying volume change or the resulting stress field from such a transformation may stop the nanocrack from further expanding.” Such mechanisms can function efficiently only for very delicately tuned microstructures and only in narrow concentration ranges. Achieving optimal conditions is an enormous challenge and requires a close collaboration of the two scientists and their team of researchers.

Metastable phases are difficult to analyse experimentally, but with DFT methods (density functional theory) which are based on quantum-mechanical principles, the parameters can be set to a point where the system is metastable. Thus the properties can be calculated under any given conditions. Parameters such as temperature, stress or volume can be changed in small steps until the phase transforms. Theory can predefine not only conditions but also compositions and thus reduce time and material needed for finding the optimum alloy.

On the other hand experimentalists have to validate the calculations. Thorough analysis of phases and phase changes is a crucial point. A unique combination of microscopic and mechanical characterization equipment at the MPIE enables the scientists to carry out in-situ investigations of such stress-induced microstructural transformations. Tasan further cooperates with the metallurgical and processing group, who will eventually produce the smart alloys. “Nowhere else than here at the MPIE would the realisation of this project be feasible”, states Tasan, “the close cooperation of physicists, materials scientists, and metallurgists and the availability of metallurgical production sites and sophisticated analysis methods are a precious advantage.”

The two group leaders are getting their research up to full speeds. Four doctoral students and three post-docs will soon support them.

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Microscopic basis of a new form of quantum magnetism

Not all magnets are the same. When we think of magnetism, we often think of magnets that stick to a refrigerator’s door. For these types of magnets, the electronic interactions…

An epigenome editing toolkit to dissect the mechanisms of gene regulation

A study from the Hackett group at EMBL Rome led to the development of a powerful epigenetic editing technology, which unlocks the ability to precisely program chromatin modifications. Understanding how…

NASA selects UF mission to better track the Earth’s water and ice

NASA has selected a team of University of Florida aerospace engineers to pursue a groundbreaking $12 million mission aimed at improving the way we track changes in Earth’s structures, such…