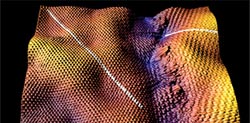

New Research Gives Insight into Graphene Grain Boundaries

Image of a grain boundary border<br><br>Making the one-atom thick sheets of carbon known as graphene in a way that could be easily integrated into mass production methods has proven difficult. Now, research from the groups of Beckman Institute faculty members Joe Lyding and Eric Pop is giving new insight into the electronics behavior of graphene. <br>

When graphene is grown, lattices of the carbon grains are formed randomly, linked together at different angles of orientation in a hexagonal network. However, when those orientations become misaligned during the growth process, defects called grain boundaries (GBs) form. These boundaries scatter the flow of electrons in graphene, a fact that is detrimental to its successful electronic performance.

Beckman Institute researchers Joe Lyding and Eric Pop and their research groups have now given new insight into the electronics behavior of graphene with grain boundaries that could guide fabrication methods toward lessening their effect. The researchers grew polycrystalline graphene by chemical vapor deposition (CVD), using scanning tunneling microscopy (STM) and spectroscopy for analysis, to examine at the atomic scale grain boundaries on a silicon wafer. They reported their results in the journal ACS Nano.

“We obtained information about electron scattering at the boundaries that shows it significantly limits the electronic performance compared to grain boundary free graphene,” Lyding said. “Grain boundaries form during graphene growth by CVD, and, while there is much worldwide effort to minimize the occurrence of grain boundaries, they are a fact of life for now.

“For electronics you would want to be able to make it on a wafer scale. Boundary free graphene is a key goal. In the interim we have to live with the grain boundaries, so understanding them is what we’re trying to do.”

I think if you have to live with grain boundaries you would like to be able to control exactly what their orientation is and choose an angle that minimizes the scattering.

– Joe Lyding

Lyding compared graphene lattices made with the CVD method to pieces of a cyclone fence.

“If you had two pieces of fence, and you laid them on the ground next to each other but they weren’t perfectly aligned, then they wouldn’t match,” he said. “That’s a grain boundary, where the lattice doesn’t match.”

The research involved Pop’s group, led by Beckman Fellow Josh Wood, growing the graphene at the Micro and Nanotechnology Lab, and transferring the thin films to a silicon (Si02) wafer. They then used the STM at Beckman developed by Lyding for analysis, led by first author Justin Koepke of Lyding’s group.

Their analysis showed that when the electrons’ itinerary takes them to a grain boundary, it is like, Lyding said, hitting a hill.

“The electrons hit this hill, they bounce off, they interfere with themselves and you actually see a standing wave pattern,” he said. “It’s a barrier so they have to go up and over that hill. Like anything else, that is going to slow them down. That’s what Justin was able to measure with these spectroscopy measurements.

“Basically a grain boundary is a resistor in series with a conductor. That’s always bad. It means it’s going to take longer for an electron to get from point A to point B with some voltage applied.”

Images from the STM reveal grain boundaries that suggest two pieces of cloth sewn together, Lyding said, by “a really bad tailor.”

In the paper, the researchers were able to report on their analysis of the orientation angles between pieces of graphene as they grew together, and found “no preferential orientation angle between grains, and the GBs are continuous across graphene wrinkles and Si02 topography.” They reported that analysis of those patterns “indicates that backscattering and intervalley scattering are the dominant mechanisms responsible for the mobility reduction in the presence of GBs in CVD-grown graphene.”

Lyding said that the relationship between the orientation angle of the pieces of graphene and the wavelength of an electron impinges on the electron’s movement at the grain boundary, leading to variations in their scattering.

“More scattering means that it is making it more difficult for an electron to move from one grain to the next,” he said. “The more difficult you make that, the lower the quality of the electronic performance of any device made from that graphene.”

The researchers work is aimed not just at understanding, but also at controlling grain boundaries. One of their findings – that GBs are aperiodic – replicated other work and could have implications for controlling them, as they wrote in the paper: “Combining the spectroscopic and scattering results suggest that GBs that are more periodic and well-ordered lead to reduced scattering from the GBs.”

“I think if you have to live with grain boundaries you would like to be able to control exactly what their orientation is and choose an angle that minimizes the scattering,” Lyding said.

Media Contact

More Information:

http://www.illinois.eduAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Microscopic basis of a new form of quantum magnetism

Not all magnets are the same. When we think of magnetism, we often think of magnets that stick to a refrigerator’s door. For these types of magnets, the electronic interactions…

An epigenome editing toolkit to dissect the mechanisms of gene regulation

A study from the Hackett group at EMBL Rome led to the development of a powerful epigenetic editing technology, which unlocks the ability to precisely program chromatin modifications. Understanding how…

NASA selects UF mission to better track the Earth’s water and ice

NASA has selected a team of University of Florida aerospace engineers to pursue a groundbreaking $12 million mission aimed at improving the way we track changes in Earth’s structures, such…