Superalloy joining for extreme applications using Transient Liquid Phase diffusion bonding

The high mechanical strength and corrosion resistant nature of oxide dispersion strengthened (ODS) superalloys puts them in demand for use in extreme applications such as turbine engines and heat exchangers. Much of their suitability for these applications is derived from their carefully tailored microstructures. Unfortunately some joining methods, like welding, can alter the desirable microstructures and therefore the properties of the superalloy.

Transient Liquid Phase (TLP) diffusion bonding has emerged as a potential joining technique for advanced alloys when fusion welding and other solid state processes are not suitable. The process involves using an interlayer between the surfaces to be bonded. The interlayer contains materials that lower the melting point. At the bonding temperature, which is below the melting temperature of the parent alloy, the interlayer melts and a joint forms by isothermal solidification.

In the present work, R.K. Saka and T.I. Khan of the University of Calgary, used Transient Liquid Phase diffusion bonding to join Inconel MA 758 using nickel based interlayers.

The researchers investigated the effect of interlayer composition, bonding time and the use of post-bond heat treatment on microstructural developments at the joint region. They found that the hold time at the bonding temperature affected the rate of isothermal solidification during the TLP bonding process. They also found that altering the hold time could produce a joint free from deleterious centerline eutectic structures. The formation of intermetallic precipitates adjacent to the joint interface were observed for bonds made using all four interlayers and a proper selection of interlayer composition was shown to reduce precipitation. The use of post-bond heat treatment was also found to help homogenization of the joint microstructure.

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

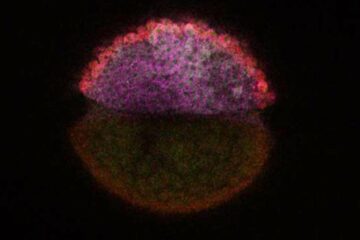

Decoding development: mRNA’s role in embryo formation

A new study at Hebrew University reveals insights into mRNA regulation during embryonic development. The study combines single-cell RNA-Seq and metabolic labeling in zebrafish embryos, distinguishing between newly-transcribed and pre-existing…

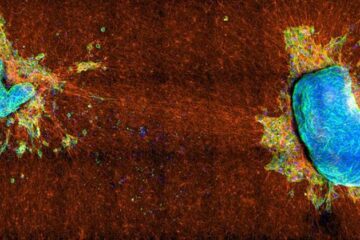

Study sheds light on cancer cell ‘tug-of-war’

How cancer cells tug against each other determines whether they can migrate elsewhere in the body. Understanding how cancerous cells spread from a primary tumor is important for any number…

Latest generation of self-dissolving stents

Magnesium implants support coronary arteries and keep them open. Constricted coronary arteries harbor dangers: Because the heart is not supplied with blood properly, this can lead to pain, cardiac arrhythmia,…