Physicists Heat Freestanding Graphene to Control Curvature of Ripples

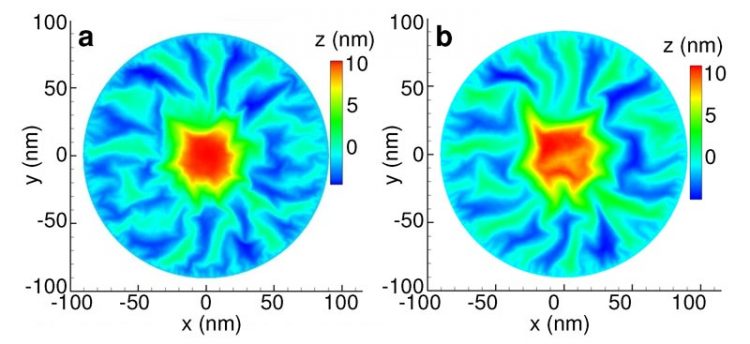

Mehdi Neek-Amal, University of Antwerp Height of the initial buckled graphene state with the bias voltage set to 3 V and the central temperature set to 300 K.

An international team of physicists, led by a research group at the University of Arkansas, has discovered that heating can be used to control the curvature of ripples in freestanding graphene.

The finding provides fundamental insight into understanding the influence temperature exerts on the dynamics of freestanding graphene. This may drive future applications of the flexible circuits of consumer devices such as cell phones and digital cameras.

While freestanding graphene offers promise as a replacement for silicon and other materials in microprocessors and next-generation energy devices, much remains unknown about its mechanical and thermal properties.

The research team published its findings on Wednesday, Sept. 17, in a paper titled “Thermal mirror buckling in freestanding graphene locally controlled by scanning tunneling microscopy” in the online journal Nature Communications, a publication of the journal Nature.

Previously, scientists have used electric voltage to cause large movements and sudden changes in the curvature of the ripples in freestanding graphene, said Paul Thibado, professor of physics at the University of Arkansas. In this paper, the team showed that an alternative method, thermal load, can be used to control these movements.

“Imagine taking a racquetball and cutting it in half,” said Thibado, an expert in experimental condensed matter physics. “You could invert it by pressing on it. That’s what we did here with a cross-section of a single ripple of freestanding graphene at the nanometer scale. Most materials expand when you heat them. Graphene contracts which is very unusual. So when we heated this cross-section, instead of expanding, it contracted, and that thermal stress caused it to buckle in the opposite direction.”

Graphene, discovered in 2004, is a one-atom-thick sheet of graphite. Electrons moving through graphite have mass and encounter resistance, while electrons moving through graphene are massless, and therefore travel much more freely. This makes graphene an excellent candidate material for use in meeting future energy needs and the fabrication of quantum computers, which make enormous calculations with little energy use.

The study was led by Peng Xu, formerly a postdoctoral research associate in the Department of Physics at the University of Arkansas and currently a postdoctoral research associate at the University of Maryland.

Xu and Thibado used scanning tunneling microscopy, which produces images of individual atoms on a surface, combined with large-scale molecular dynamic simulations to demonstrate the thermal mirror buckling.

In the paper, the third published in a major journal by the research team in 2014, they propose a concept for a new instrument that capitalizes on the control of the mirror buckling: a nanoscale electro-thermal-mechanical device.

Such a device would provide an alternative to microelectromechanical systems, which are tiny machines that are activated electrically. The advantage of this nanoscale electro-thermal-mechanical device would be the ability to change its output using electricity or heat. In addition, thermal loads can provide a significantly larger force.

The study, funded by the Office of Naval Research and the National Science Foundation, was conducted primarily through a research partnership between the University of Arkansas and the University of Antwerp in Belgium.

The results were obtained through a collaborative effort with University of Arkansas physics graduate students Steven D. Barber, James Kevin Schoelz and Matthew L. Ackerman; Mehdi Neek-Amal of the University of Antwerp and Shahid Rajaee Teacher Training University in Iran, Ali Sadeghi of the University of Basel in Switzerland and Francois Peeters of the University of Antwerp.

Contact:

Paul Thibado, professor, physics

J. William Fulbright College of Arts and Sciences

479-575-7932, thibado@uark.edu

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Microscopic basis of a new form of quantum magnetism

Not all magnets are the same. When we think of magnetism, we often think of magnets that stick to a refrigerator’s door. For these types of magnets, the electronic interactions…

An epigenome editing toolkit to dissect the mechanisms of gene regulation

A study from the Hackett group at EMBL Rome led to the development of a powerful epigenetic editing technology, which unlocks the ability to precisely program chromatin modifications. Understanding how…

NASA selects UF mission to better track the Earth’s water and ice

NASA has selected a team of University of Florida aerospace engineers to pursue a groundbreaking $12 million mission aimed at improving the way we track changes in Earth’s structures, such…