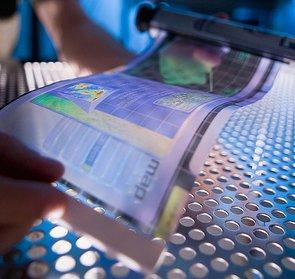

Improvements in Transistors Will Make Flexible Plastic Computers a Reality

Full Image credit: "Flexible display" by RDECOM - http://www.flickr.com/photos/rdecom/4146880795/. Licensed under CC BY 1.0 via Wikimedia Commons - http://commons.wikimedia.org/wiki/File:Flexible_display.jpg#mediaviewer/File:Flexible_display.jpg

The scientists reviewed the latest developments in research on photoactive organic field-effect transistors; devices that incorporate organic semi-conductors, amplify weak electronic signals, and either emit or receive light.

Organic field-effect transistors (OFETs) were developed to produce low-cost, large-area electronics, such as printable and/or flexible electronic devices.

The review was published in Science and Technology of Advanced Materials.

The researchers reported that much progress has been made in the development of light-emitting organic field-effect transistors (LE-OFETs) since they first appeared in 2003.

Research in this area has resulted in advances in the manufacture of novel organic photonics applications using cost-effective approaches. Light emission efficiency and brightness of these transistors will soon improve. And the production of new display technologies is expected to be the result of further research.

LE-OFETs are also expected to become fully compatible with well-established electronic technologies. This may allow further development of optical communication systems and optoelectronic systems, such as those using laser technologies.

LE-OFETs are being used to develop, for example, flexible, transparent computer screens. These screens are purported to provide faster response times, better efficiency, and no need for backlighting. They also have very low energy needs.

Light-receiving organic field-effect transistors (LR-OFETs), on the other hand, are much less developed than their light-emitting siblings. LR-OFETs convert light into electrical signals, opening a way to new optoelectronic devices.

Phototransistors, used in CD players, are an example of such devices that hold much promise. But their durability needs to be improved for them to be used in more flexible applications.

Further development is also required in other kinds of light-receiving OFETs before they can be used in all-plastic computing devices.

Light-receiving organic field-effect transistors could open new frontiers for photonic and electronic devices. Flexible displays, in which all the device components – such as the light-emitting parts, the switching parts, and the substrates – consist of plastic materials have already been developed and will appear on the market in the near future. However, similar memory devices are still lacking. If “plastic memory” is developed, it will open a new frontier.

The researchers found that the performance of devices that incorporate both light-emitting and light-receiving transistors faces several issues. They recommend interdisciplinary collaborations between organic chemists and device physicists for these issues to be resolved. They estimate that it will still be another ten years before all-plastic, flexible computing devices appear on the market.

For more information, contact

Yutaka Wakayama

International Center for Materials Nanoarchitectonics (WPI-MANA)

National Institute for Materials Science (NIMS)

1-1 Namiki, Tsukuba 305-0044, Japan

E-mail: WAKAYAMA.Yutaka@nims.go.jp

JOURNAL INFORMATION

Science and Technology of Advanced Materials (STAM) is the leading open access, international journal for outstanding research articles across all aspects of materials science. Click on link below for more information.

Associated links

Science and Technology of Advanced Materials

Link to research paper

Journal information

Science and Technology of Advanced Materials

doi:10.1088/1468-6996/15/2/024202

Sci. Technol. Adv. Mater. 15 (2014) 024202

Media Contact

More Information:

http://www.researchsea.comAll latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Why getting in touch with our ‘gerbil brain’ could help machines listen better

Macquarie University researchers have debunked a 75-year-old theory about how humans determine where sounds are coming from, and it could unlock the secret to creating a next generation of more…

Attosecond core-level spectroscopy reveals real-time molecular dynamics

Chemical reactions are complex mechanisms. Many different dynamical processes are involved, affecting both the electrons and the nucleus of the present atoms. Very often the strongly coupled electron and nuclear…

Free-forming organelles help plants adapt to climate change

Scientists uncover how plants “see” shades of light, temperature. Plants’ ability to sense light and temperature, and their ability to adapt to climate change, hinges on free-forming structures in their…