A shock to pollution in chemistry

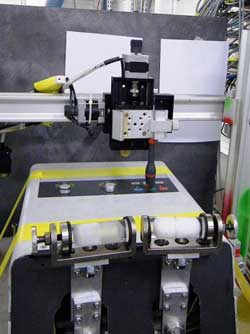

The experimental setup at the ESRF in Grenoble (France) with the milling jar containing the white ZIF-8 shown in the front, mounted on a modified industrial mill. The X-rays enter at the yellow circle, and the X-ray detector is set several meters behind the viewer. The robot with the screw driver to push the buttons was devised by Frank Adams, team member from MPI for Solid State Research in Stuttgart, is positioned above the mill and enables remote control. This is necessary because of the lethal level of X-rays during the experiment, which takes places inside a cabin shielded by several centimetres of lead.<br><br>Credit: Credit T. Frišèiæ<br>

Solvents are omnipresent in the chemical industry, and are a major environmental and safety concern. Therefore the large interest in mechanochemistry: an energy-efficient alternative that avoids using bulk solvents and uses high-frequency milling to drive reactions.

Milling is achieved by the intense impact of steel balls in a rapidly moving jar, which hinders the direct observation of underlying chemistry. Scientists have now for the first time studied a milling reaction in real time, using highly penetrating X-rays to observe the surprisingly rapid transformations as the mill mixes, grinds and transforms simple ingredients into a complex product. This study opens new opportunities in Green Chemistry and environmentally-friendly synthesis. The results are published in Nature Chemistry dated 2 December 2012.

The international team of scientists was led by Tomislav Friščić of McGill University (Canada) in collaboration with Ivan Halasz from the University of Zagreb (Croatia), scientists from the University of Cambridge (UK), Max-Planck-Institute for Solid State Research in Stuttgart (Germany) and the European Synchrotron Radiation Facility (ESRF) in Grenoble (France).

Everybody remembering their chemistry lessons will recall mixing ingredients into a solvent. This was sometimes water, but more often a solvent such as ether (flammable), chloroform (toxic) or benzene (cancerogenic). Bulk solvents used in industry pose a serious threat to human health and the environment, and their responsible management has a considerable cost.

Although it is well known that mechanical action can break chemical bonds, for example in tear and wear of textile fibres, it is much less known that mechanical force can also be used to synthesize new chemical compounds and materials. In recent years, ball milling has become increasingly popular in the production of highly complex chemical structures. In such synthesis, steel balls are shaken with the reactants and catalysts in a rapidly vibrating jar. Chemical transformations take place at the sites of ball collision, where impact causes instant “hot spots” of localized heat and pressure. This is difficult to model and, without access to real time reaction monitoring, mechanochemistry remained poorly understood. “When we set out to study these reactions, the challenge was to observe the entire reaction without disturbing it, in particular the short-lived intermediates that appear and disappear under continuous impact in less than a minute”, says Tomislav Friščić, a Professor at McGill University in Montreal.

The team of scientists chose to study mechanochemical production of the metal-organic framework ZIF-8 (sold as Basolite Z1200) from the simplest and non-toxic components. Materials such as ZIF-8 are rapidly gaining popularity for capturing large amounts of CO2 and, if manufactured cheaply and sustainably, could become widely used for carbon capture, catalysis and even hydrogen storage. “The team came to the ESRF because of our high-energy X-rays capable of penetrating 3 mm thick walls of a rapidly moving reaction jar made of steel, aluminium or plastic.

The X-ray beam must get inside the jar to probe the mechanochemical formation of ZIF-8, and then out again to detect the changes as they happened”, says Simon Kimber, a scientist at the European Synchrotron Radiation Facility (ESRF) in Grenoble, who is a member of the team. This unprecedented methodology enabled the real-time observation of reaction kinetics, reaction intermediates and the development of their respective nanoparticles.

This technique is not limited to ZIF-8. In principle, all types of chemical reactions in a ball mill can now be studied and optimized for industrial processing. 'These results hold promise for improving the fundamental understanding of processes central to pharmaceutical, metallurgical, cement and mineral industries and should enable a more efficient use of energy, reduction in solvent and optimize the use of often expensive catalysts. This translates into good news for the environment, the industry and the consumers who will have to pay less”, concludes Tomislav Friščić.

Media Contact

More Information:

http://www.esrf.frAll latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

Microscopic basis of a new form of quantum magnetism

Not all magnets are the same. When we think of magnetism, we often think of magnets that stick to a refrigerator’s door. For these types of magnets, the electronic interactions…

An epigenome editing toolkit to dissect the mechanisms of gene regulation

A study from the Hackett group at EMBL Rome led to the development of a powerful epigenetic editing technology, which unlocks the ability to precisely program chromatin modifications. Understanding how…

NASA selects UF mission to better track the Earth’s water and ice

NASA has selected a team of University of Florida aerospace engineers to pursue a groundbreaking $12 million mission aimed at improving the way we track changes in Earth’s structures, such…