Materials science brings new forest product opportunities

“Forest cluster companies operating in Finland are on the look out for new forest products. In order to be able to meet the challenges of these companies we need to improve the current level of know-how in wood-based products and wood processing at molecular level. New territory has been charted for example in the areas of composite and nanomaterials,” says Professor Janne Laine of the Helsinki University of Technology’s Department of Forest Products Technology.

Interest in cellulose-based nanofibres is primarily driven by its environmental value as a biomaterial. It is also known that nanomaterials can be used, for example, to achieve strength properties which are not attainable with particles of bigger size classes. Furthermore, the smaller the particle is, the bigger the surface area, which in turn increases the desired interactivity with other materials.

“One of the main application targets for new materials is the car industry, which wants to use lightweight cellulose fibres in car interior panelling. Estimates in terms of volume of the natural fibre requirement of the European car industry in 2010 are extremely substantial,” says Laine.

Professor Laine’s research team is one of five teams involved in examining and developing cellulose-based nanofibres as part of the Finnish-Swedish Wood Material Science and Engineering research programme.

Research demonstrates the versatility of wood fibre

According to Professor Janne Laine, the Nanostructured Cellulose Products research project has shown that wood fibre can be used to make an extremely versatile range of materials, both for traditional wood processing industry products as well as for totally new applications.

Cellulose fibres (30 micrometers wide, 2–3 millimetres long) consist of nanometre-scale microfibrils (4 nm wide, 100–200 nm long).

The chief objective of the project has been to produce uniform quality nanofibre (microfibrillated cellulose, MFC) from cellulose fibres by combining enzymatic or chemical treatment with mechanical processing. The second objective has been to attempt to functionalise the surfaces of the microfibrils, e.g. by means of polymers in order to be able to utilise the converted fibrils in as many materials as possible. The third objective has been to demonstrate how cellulose fibrils can give totally new properties to a range of different materials.

The project has achieved an 80 percent reduction in the energy requirement of microfibrillar cellulose manufacture as compared to levels formerly claimed in literature. In addition, enzymatic pre-treatment combined with specific mechanical treatments has produced microfibrils of extremely high and uniform quality.

Boosting material conductivity, strength, elasticity, lightness and self-cleaning properties

“We’ve succeeded in modifying the surfaces of microfibrils e.g. by means of different polymers, which has, for instance, enabled us to make their surfaces more electrically charged. Microfibrils give considerable toughness and strength to traditional paper products even in small quantities. Correspondingly, microfibrils, as so-called nanocomposite structures, form an extremely high-strength material (e.g. film) the plasticity (elasticity) of which is possible to regulate for example by means of starch,” says Laine.

“Cellulose microfibrils can also be used to make ultra-light materials. By combining fibrils with conductive polymers, we’ve been able to make cellulose based structures which conduct electricity. It’s also been possible to coat microfibrils with a thin layer of titanium dioxide, which makes the material photocatalytically active. Titanium dioxide coated microfibrillar cellulose could be used, for instance, in solar cells and applications in which self-cleaning surfaces are needed, such as filters.”

Media Contact

All latest news from the category: Agricultural and Forestry Science

Newest articles

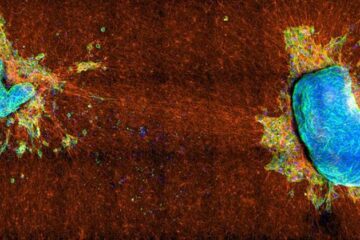

Study sheds light on cancer cell ‘tug-of-war’

How cancer cells tug against each other determines whether they can migrate elsewhere in the body. Understanding how cancerous cells spread from a primary tumor is important for any number…

Latest generation of self-dissolving stents

Magnesium implants support coronary arteries and keep them open. Constricted coronary arteries harbor dangers: Because the heart is not supplied with blood properly, this can lead to pain, cardiac arrhythmia,…

Stopping blood cancer

The MHH joint project TARGET-MPN is investigating why the disease persists and progresses in malignant bone marrow diseases from the group of myeloproliferative neoplasms despite targeted treatment. Haematopoietic stem cells…