New Technique Allows Ultrasound To Penetrate Bone, Metal

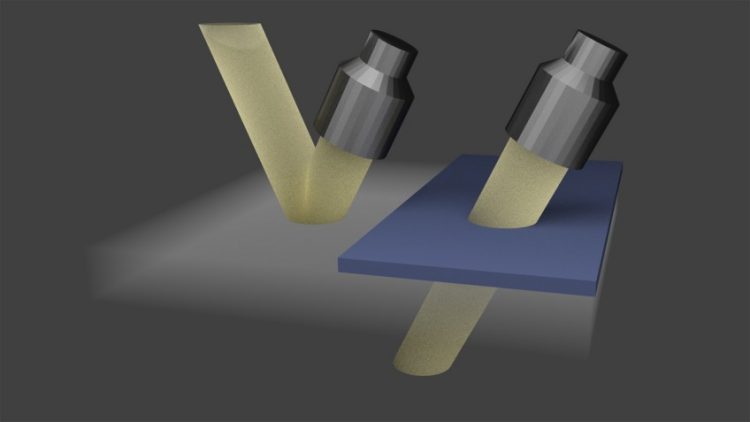

Using a new technique, “it’s as if the aberrating layer isn’t even there,” says researcher Yun Jing. Image credit: Yun Jing.

“We’ve designed complementary metamaterials that will make it easier for medical professionals to use ultrasound for diagnostic or therapeutic applications, such as monitoring blood flow in the brain or to treat brain tumors,” says Tarry Chen Shen, a Ph.D. student at NC State and lead author of a paper on the work. “This has been difficult in the past because the skull distorts the ultrasound’s acoustic field.”

“These metamaterials could also be used in industrial settings,” says Dr. Yun Jing, an assistant professor of mechanical and aerospace engineering at NC State and senior author of the paper. “For example, it would allow you to use ultrasound to detect cracks in airplane wings under the wing’s metal ‘skin.’”

Ultrasound imaging works by emitting high frequency acoustic waves. When those waves bounce off an object, they return to the ultrasound equipment, which translates the waves into an image.

But some materials, such as bone or metal, have physical characteristics that block or distort ultrasound’s acoustic waves. These materials are called aberrating layers.

The researchers addressed this problem by designing customized metamaterial structures that take into account the acoustic properties of the aberrating layer and offsetting them. The metamaterial structure uses a series of membranes and small tubes to achieve the desired acoustic characteristics.

The researchers have tested the technique using computer simulations and are in the process of developing and testing a physical prototype.

In simulations, only 28 percent of ultrasound wave energy makes it past an aberrating layer of bone when the metamaterial structure is not in place. But with the metamaterial structure, the simulation shows that 88 percent of ultrasound wave energy passes through the aberrating layer.

“In effect, it’s as if the aberrating layer isn’t even there,” Jing says.

The technique can be used for ultrasound imaging, as well as therapeutically – such as using ultrasound to apply energy to brain tumors, in order to burn them.

The paper, “An Anisotropic Complementary Acoustic Metamaterial for Cancelling out Aberrating Layers,” is published online in the open access journal Physical Review X. The paper was co-authored by Drs. Jun Xu and Nicholas Fang at MIT. Jing acknowledges financial support from NC Space Grant via a New Investigator award. Xu and Fang acknowledge support from the Office of Naval Research under grant N00014-13-1-0631.

-shipman-

Note to Editors: The study abstract follows.

“An Anisotropic Complementary Acoustic Metamaterial for Cancelling out Aberrating Layers”

Authors: Chen Shen and Yun Jing, North Carolina State University; Jun Xu and Nicholas X. Fang, Massachusetts Institute of Technology

Published: Nov. 19 in Physical Review X (open access)

DOI: http://dx.doi.org/10.1103/PhysRevX.4.041033

Abstract: In this paper, we investigate a type of anisotropic, acoustic complementary metamaterials (CMM) and their application in restoring acoustic fields distorted by aberrating layers. The proposed quasi 2-D, non-resonant CMM consists of unit cells formed by membranes and side branches with open ends. Simultaneously anisotropic and negative density is achieved by assigning membranes facing each direction (x- and y-direction) with different thicknesses while the compressibility is tuned by the side branches. Numerical examples demonstrate that, the CMM, when placed adjacent to a strongly aberrating layer, could acoustically cancel out that aberrating layer. This leads to dramatically reduced acoustic field distortion and enhanced sound transmission, therefore virtually removing the layer in a noninvasive manner. In the example where a focused beam is studied, using the CMM, the acoustic intensity at the focus is increased from 28% to 88% of the intensity in the control case (without the aberrating layer and the CMM). The proposed acoustic CMM has a wide realm of potential applications, such as cloaking, all angle anti-reflection layers, ultrasound imaging, detection and treatment through aberrating layers.

Media Contact

All latest news from the category: Medical Engineering

The development of medical equipment, products and technical procedures is characterized by high research and development costs in a variety of fields related to the study of human medicine.

innovations-report provides informative and stimulating reports and articles on topics ranging from imaging processes, cell and tissue techniques, optical techniques, implants, orthopedic aids, clinical and medical office equipment, dialysis systems and x-ray/radiation monitoring devices to endoscopy, ultrasound, surgical techniques, and dental materials.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…