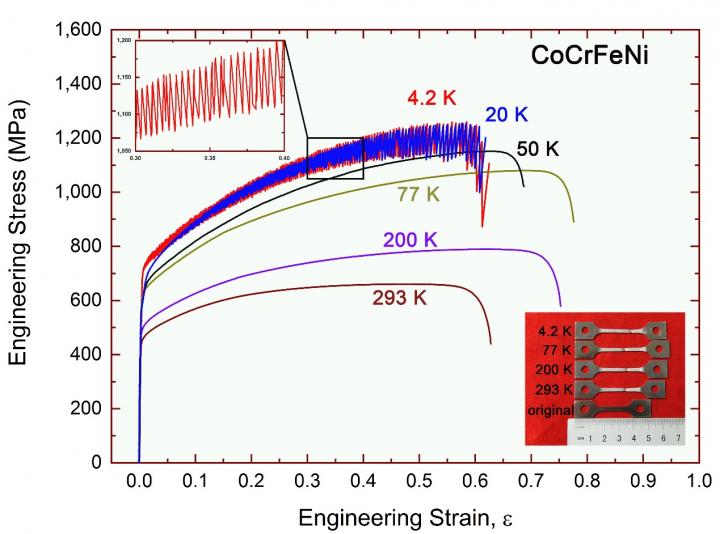

The tensile test of CoCrFeNi high-entropy alloy at different temperatures.

Credit: ©Science China Press

As a fire-new material, high-entropy alloys (HEAs) exhibit an extremely-broad philosophy on how to combine elements. The potent mixture strategy makes the opportunity to find something new and exciting very high.

In this circumstance, the service performance of high-entropy alloy under extremely condition inevitably becomes something we're curious about.

In this paper, the authors have assessed the mechanical response of the CoCrFeNi high-entropy alloy (see the results in Figure 1), and found that this alloy exhibit a high ultimate tensile strength of 1.26 GPa and elongation to failure of 62% at 4.2 K, which are the best among almost all of metallic materials, as shown in Figure 2.

This study witnesses the extensive deformation twinning and phase transformation from a face-centered cubic (FCC) structure to a hexagonal close-packed (HCP) structure are responsible for the superior mechanical performance at such low temperature.

Moreover, the serration feature appears in the stress-strain curves of this alloy at liquid-helium temperatures and the authors deduce the high-density twinning and phase transformation contribute to the serration feature, and that the FCC-HCP transition makes the serrated flow unstable.

The results of high-mechanical performance at low temperatures, phase transition, and serration, not only exhibit a significant breakthrough in the fundamental materials science, but also indicate HEAs' tremendous prospects and potential applications in the field of extreme cryogenic engineering.

###

https:/