Researchers at the University of North Carolina have created microscopic soft robots shaped like flowers that can change shape and behavior in response to their surroundings, just like living organisms do. These tiny “DNA flowers” are made from special crystals formed by combining DNA and inorganic materials. They can reversibly fold and unfold in seconds, making them among the most dynamic materials ever developed on such a small scale. Each flower’s DNA acts like a tiny computer program, telling it…

Researchers have created a polymer “Chinese lantern” that can snap into more than a dozen curved, three-dimensional shapes by compressing or twisting the original structure. This rapid shape-shifting behavior can be controlled remotely using a magnetic field, allowing the structure to be used for a variety of applications. The basic lantern object is made by cutting a polymer sheet into a diamond-like parallelogram shape, then cutting a row of parallel lines across the center of each sheet. This creates a…

Made from eco-friendly elements, this innovative material holds promise for energy storage, hydrogen production, and environmental remediation Meeting global energy demands while mitigating environmental harm remains a major challenge, as many current solutions rely on expensive and toxic noble metals. In a recent study, researchers from Japan successfully developed a novel copper–cobalt oxide composite anchored on nitrogen-doped carbon nanostructures. Synthesized via a simple method, this material excels in energy storage, environmental remediation, and water splitting—offering a low-cost and sustainable alternative…

Researchers investigate clean and efficient new method for iron production Researchers investigate clean and efficient new method for iron production MINNEAPOLIS / ST. PAUL (09/29/2025) — A research team at the University of Minnesota Twin Cities has investigated a new method to produce iron, the main component of steel. For the first time, the researchers were able to observe chemical reactions and iron formation in real-time at the nanometer scale. This breakthrough has the potential to transform the global iron…

Global electricity consumption is rising at an unprecedented pace. According to the International Energy Agency, electricity is projected to account for more than 50% of global energy use within the next 25 years, compared to the current 20%. This creates a pressing need for sustainable, efficient energy conversion methods, particularly advanced solar technologies. “To meet the demand, there is a significant and growing need for new, environmentally friendly and efficient energy conversion methods, such as more efficient solar cells. Our…

A research team from the Tokyo University of Science (TUS) and the National Institute of Advanced Industrial Science and Technology (AIST) has developed a groundbreaking measurement system that reveals how energy is lost in soft magnetic materials. The discovery could accelerate the design of next-generation power electronics, making transformers, motors, and renewable energy systems smaller, lighter, and more efficient. Cracking the Puzzle of Iron Loss Soft magnetic materials are essential to devices such as transformers and generators, but their efficiency…

A team of scientists from Korea and Japan has discovered a new type of crystal that can repeatedly absorb and release oxygen under relatively mild conditions. This unusual “breathing” ability could pave the way for advances in clean energy systems, electronics, and smart building technologies. The material is a novel metal oxide composed of strontium, iron, and cobalt. Unlike most oxygen-controlling materials, which are fragile or only function at extremely high temperatures, this crystal remains stable and operates at lower…

Synopsis A research team led by Professor Akihiko Nakamura from the Research Institute of Green Science and Technology at Shizuoka University, in collaboration with Researchers Takashi Matsuzaki and Toshiyuki Saeki from Kirin Holdings Co., Ltd., Professor Ryota Iino from the Institute for Molecular Science, and Professor Nobuyasu Koga from the Institute for Protein Research at Osaka University, has successfully engineered a novel PET hydrolase enzyme, PET2-21M, significantly enhancing the biodegradation of bottle-grade polyethylene terephthalate (PET) plastics. Significant activity was also…

A research team in South Korea has created an innovative transfer printing process that applies protective thin layers to lithium metal surfaces, addressing the persistent dendrite problem affecting next-generation lithium-metal batteries. Dr. Jungdon Suk’s team at the Korea Research Institute of Chemical Technology (KRICT) has successfully applied hybrid protective layers made of solid polymers and ceramics onto lithium metal through a solvent-free method. This process allows for uniform coating over extensive regions without compromising the reactive lithium surface, representing a…

MINNEAPOLIS / ST. PAUL (07/18/2025) — Researchers at the University of Minnesota Twin Cities have uncovered a promising path to make computer memory faster and far more energy-efficient through the use of a novel material, according to a recent study published in Advanced Materials. The university team has also filed a patent for this technology. As technology evolves, the need for more efficient memory continues to grow. Scientists are actively exploring advanced materials that can support higher performance with lower…

Coordination nanosheets—two-dimensional materials made by linking metal ions with organic ligands—have captured attention in recent years due to their remarkable conductivity, redox activity, and catalytic performance. They are especially useful in areas such as energy storage, sensors, and electronics. However, producing these nanosheets, particularly heterometallic ones (which contain two or more metal ions), has traditionally relied on a complex two-phase interfacial reaction and lacked precise structural control. Addressing this challenge, a team led by Professor Hiroshi Nishihara from the Research…

The majority of Earth’s water is unfit for human consumption since it is trapped in salty oceans. Although desalination plants are capable of turning saltwater into freshwater, they usually use a lot of energy. Scientists have now created a novel, sponge-like substance that effectively turns saltwater into drinkable water when combined with sunlight and a basic plastic cover. Their research, which was published in ACS Energy Letters, shows that an outdoor proof-of-concept that used just natural sunlight to successfully produce…

The scientific team led by Dr. Miloslav Polášek at IOCB Prague has come up with a technique to separate and purify rare earth elements (lanthanides). These are critical to industries ranging from electronics and medicine to automotive and defense. This novel method enables the extraction of metals like neodymium and dysprosium from used neodymium magnets. It is an important component in electric vehicles and wind turbines. Eco-Friendly and Solvent-Free Process Unlike conventional methods that rely on harsh chemicals and generate…

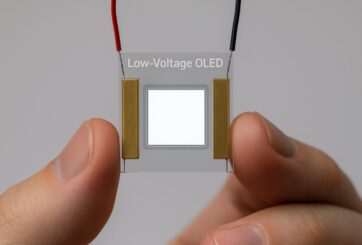

Inserting a nanometer-thin spacer in ExUC-OLEDs improves energy transfer, enhances blue light emission 77-fold, paving way for lightweight, low-voltage, and more flexible OLEDs Organic light-emitting diodes (OLEDs) have transformed display and lighting technology with their vivid colors, deep contrast, and energy efficiency. As demand grows for lighter, thinner, and more energy-saving devices—especially in wearables, foldables, and portable electronics—there’s increasing interest in OLEDs that can operate at lower voltages without compromising performance. A new type of OLEDs, known as exciplex upconversion…

Tokyo, Japan—The COVID-19 pandemic increased public awareness of the importance of mask use for personal protection. However, when the mesh size of mask fabrics is small enough to capture viruses, which are usually around one hundred nanometers in size, the fabric typically also restricts air flow, resulting in user discomfort. But now, researchers from Japan have found a way to avoid this. In a study published this month in Materials Advances, researchers from the Institute of Industrial Science, The University…

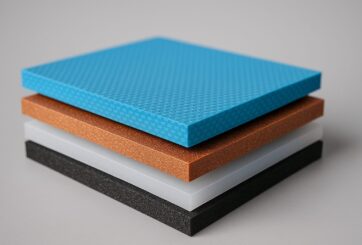

CHAMPAIGN, Ill. — Millions of years of evolution have enabled some marine animals to grow complex protective shells composed of multiple layers that work together to dissipate physical stress. In a new study, engineers have found a way to mimic the behavior of this type of layered material, such as seashell nacre, by programming individual layers of synthetic material to work collaboratively under stress. The new material design is poised to enhance energy-absorbing systems such as wearable bandages and car…