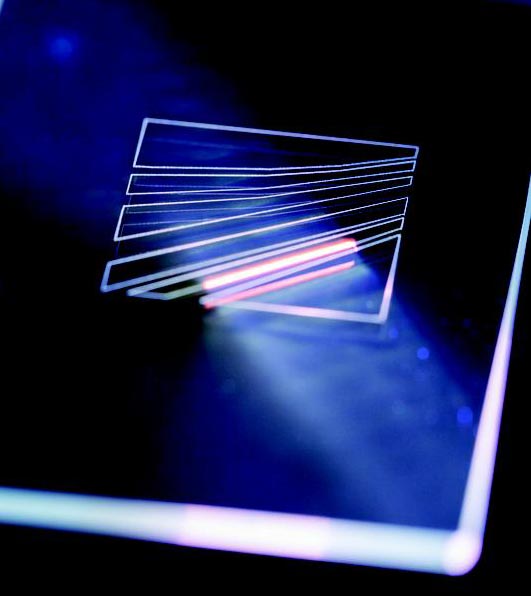

Creating microstructures on glass using an ultrafast laser.

Fraunhofer ILT, Aachen/Germany

From April 22 to 23, 2015, the 3RD UKP-Workshop: Ultrafast Laser Technology in Aachen, Germany, will see experts from the worlds of science and research showing laser users how they can exploit new ultrafast laser tools in their laser processes without damaging the materials they are working on – even at high average outputs.

Opportunities and challenges for precision manufacturing

Ultrafast lasers (USP) are currently used in just about all industrial manufacturing applications that require high-precision processing without causing damage to the material. Thanks to their extremely short pulse durations of just a few picoseconds or femtoseconds, USP lasers can process materials without causing significant heat-affected zones or melt formation.

The advantages of this technique – typically referred to as »cold ablation« – are put to good use in processes such as drilling nozzles, cutting thin glass, and creating structures on tools. USP lasers are particularly useful in glass working because they minimize stress in the material and help to avoid damage such as crack formation, which is an essential prerequisite for making the cutting process reproducible. As a result, there is particularly high demand for USP lasers in glass and sapphire processing applications such as cutting display glass and watch glass.

Spoiled for choice – which laser is best?

When it comes to high-precision structuring, drilling and cutting, users can choose between a wide range of USP laser systems with power ratings of up to 100 W. These can be used to perform processes such as direct cutting and ablation as well as two-stage processes, such as modification and etching with the SLE technique.

However, increasing the laser power to boost productivity leads to quality-deteriorating effects, for instance thermal accumulation, plasma formation and self-focusing, which can cause changes in the material and melt formation. Strategies for each individual process can be used to counter these effects, including modifying pulse duration, pulse shape in the time domain, focusing and beam forming (scanner system). However, choosing the right laser system and processing strategy poses a significant challenge to users – a challenge that can only be overcome by acquiring in-depth knowledge of the process involved.

Creating clarity through an integrated approach

Experts from science and industry will be shedding light on the complex issues involved in USP laser processing at the 3RD UKP-Workshop: Ultrafast Laser Technology in Aachen. At the same time, they will be explaining individual laser techniques, such as cutting thin glass and high-precision drilling. As well as considering the different laser concepts and machine components used in high-speed processing, they will also take into account the relevant process strategies and differing needs and experience of individual users.

The speakers will present the very latest developments in ultrafast laser systems and highlight solutions for a wide range of different processes. In this way, they will provide users with a valuable boost in choosing the right laser system for their specific needs and help them to implement powerful USP laser systems in the most cost-effective way.

3RD UKP-Workshop: Ultrafast Laser Technology in Aachen

For the third time, the Fraunhofer Institute for Laser Technology ILT will be running its biennial UKP-Workshop: Ultrafast Laser Technology in Aachen on April 22 and 23, 2015. More than 20 speakers from 8 different countries will be covering the fundamentals of ultrafast laser technology as well as providing an overview of current beam source developments and new systems technologies, including multiple beam optics and new scanner concepts.

There will also be a number of presentations in the field of process engineering examining cutting-edge applications and approaches that have the potential to extend existing boundaries in the realms of material types, processing speed and processing quality.

The organizers anticipate some 160 people will attend the event. Many of these are likely to come from abroad, reflecting the international relevance of the workshop topic. The conference will therefore be held in English with simultaneous translation into German. Please visit www.ultrafast-laser.com to sign up for the workshop.

Contact

Dipl.-Ing. Nelli Hambach

Micro- and Nano Structuring

Telephone +49 241 8906-358

nelli.hambach@ilt.fraunhofer.de

Dr. Arnold Gillner

Head of the competence area Ablation and Joining

Telephone +49 241 8906-148

arnold.gillner@ilt.fraunhofer.de

Fraunhofer Institute for Laser Technology ILT

Steinbachstraße 15

52074 Aachen