NASA marks major milestones for the James Webb Space Telescope

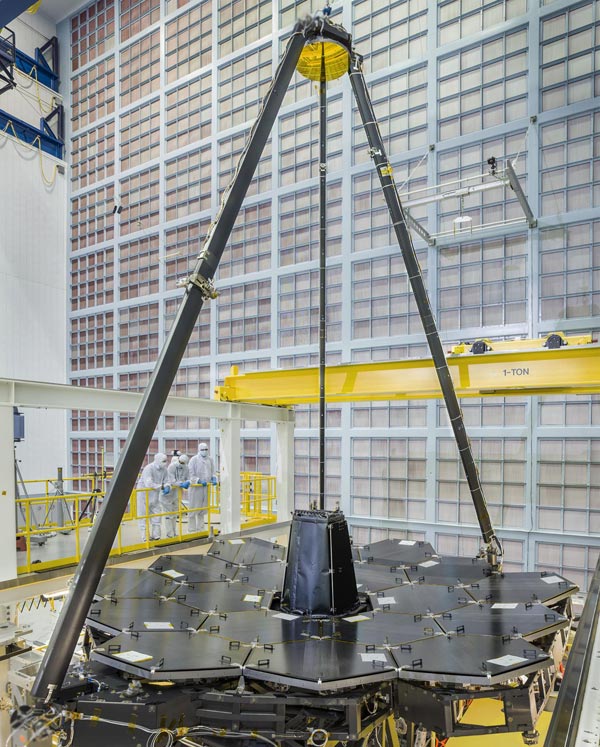

NASA's James Webb Space Telescope completed primary mirror sits in the cleanroom at NASA Goddard Space Flight Center, and supported over it on the tripod is the secondary mirror.

Credits: NASA/Chris Gunn

After over a year of planning, nearly four months of final cryo (cold) testing and monitoring, the testing on the science instruments module of the observatory was completed.

They were removed from a giant thermal vacuum chamber at NASA's Goddard Space Flight Center in Greenbelt, Maryland called the Space Environment Simulator, or SES, that duplicates the vacuum and extreme temperatures of space.

The SES is a 40-foot-tall, 27-foot-diameter cylindrical chamber that eliminates almost all of the air with vacuum pumps and uses liquid nitrogen and even colder gaseous helium to drop the temperature.

“We needed to test these instruments against the cold because one of the more difficult things on this project is that we are operating at very cold temperatures,” said Begoña Vila, NASA's Cryogenic Test Lead for the ISIM at NASA Goddard.

The ISIM, or Integrated Science Instrument Module is one of three major elements that comprise the James Webb Space Telescope Observatory flight system. “We needed to make sure everything moves and behaves the way we expect them to in space. Everything has to be very precisely aligned for the cameras to take their measurements at those cold temperatures which they are optimized for.”

The testing is critical because at these instrument's final destination in space, one million miles away from Earth, it will operate at incredibly cold temperatures of minus 387 degrees Fahrenheit, or 40 degrees Kelvin. This is 260 degrees Fahrenheit colder than any place on the Earth's surface has ever been.

“This is the culmination of a lot of hard work by a lot of people who have been working for many, many years,” said Jamie Dunn, NASA's Integrated Science Instrument Module Manager for the Webb telescope at Goddard. “This final test was phenomenal, everything is working spectacularly well.

The science instrument modules tested consist of the mid-infrared instrument (MIRI), jointly developed by a nationally funded European Consortium under the auspices of the European Space Agency (ESA) and the Jet Propulsion Laboratory; a near infrared spectrometer (NIRSpec), jointly developed by Airbus for ESA and the U.S.; the Fine Guidance Sensor/ Near-InfraRed Imager and Slitless Spectrograph, provided by the the Canadian Space Agency and developed by COM DEV International, Cambridge, Ontario, Canada; and Near Infrared Camera (NIRCam), built by a team at the University of Arizona and Lockheed Martin's Advanced Technology Center.

On March 6, 2016, shortly after the successful instrument testing, the last mirrors in Webb's optical path were installed into the telescope. Now the telescope is officially optically complete.

“Optical completeness means that all of the telescope mirrors have been installed,” said Lee Feinberg, the Webb telescope Optical Telescope Element Manager, at Goddard. “We can now say 'we have a telescope'–it's a huge milestone many years in the making.”

Once launched into space, this telescope will capture faint light from the very first objects that illuminated the universe after the Big Bang. To make observations of galaxies and stars from that far away, the telescope has a unique set of mirrors: a 25 square meter (~269 square feet) primary mirror consisting of 18 hexagonal concave segments, a secondary rounded, convex mirror, a tertiary concave mirror, and a moveable turning flat mirror called the fine steering mirror.

The Webb telescope's primary mirror segments and secondary mirror are made of beryllium, which was selected for its stiffness, light weight and stability at cryogenic temperatures. Bare beryllium is not very reflective of near-infrared light, so each mirror is coated with about 0.12 ounces of gold to enable it to efficiently reflect infrared light (which is what the Webb telescope's cameras see).

The anchor of the optical system is the last (third) set of mirrors–the tertiary mirror and the fine steering mirror. These two mirrors are located inside the Aft Optics Subsystem (AOS), which is a phone booth-sized beryllium structure surrounded in black covering. It is located right in the center of the primary mirror, and about half of it sticks up above the primary mirror.

After incoming light hits the expansive primary mirror, it is directed onto the small circular secondary mirror, which reflects it back in the direction of the primary mirror and into the AOS. [Animation: https:/

“The completion of these major milestones represent huge achievements for NASA and our industry, European, Canadian, and academic partners. ISIM and the telescope only reached these milestones because of the passion, dedication, and imagination of an outstanding group of individuals. The next major step is assembling the instrument module and the telescope together to complete the entire 'cold' section of the Webb observatory,” said Bill Ochs, Webb telescope Project Manager at Goddard.

The mirrors were built by Ball Aerospace & Technologies Corporation, in Boulder, Colorado. Ball is the principal subcontractor to Northrop Grumman for the optical technology and optical system design. The installation of the mirrors onto the telescope structure is performed by Harris Corporation, a subcontractor to Northrop Grumman. Harris Corporation leads integration and testing for the telescope.

The most powerful space telescope ever built, the Webb telescope will provide images of the first galaxies ever formed and study planets around distant stars. It is a joint project of NASA, the European Space Agency and the Canadian Space Agency.

For more information about what's coming up for the Webb until launch, visit: http://www.

For more information about the Webb telescope, please visit: http://www.