In the latest Version 4.7 of the Sinumerik Operate user interface, Siemens has improved the multitasking machining with machine tools in order to, for example, allow the complete machining of even highly complex workpieces.

- New software version 4.7 of the Sinumerik Operate user interface optimized for multitasking machine tools

- Cross-technology, standardized look-and-feel for milling, turning, drilling and measuring functions

- Complete machining in one clamping

- Flexible NC programming using programGuide and ShopMill/ShopTurn

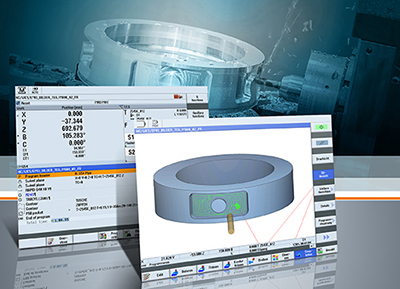

In the latest Version 4.7 of the Sinumerik Operate user interface, Siemens has improved the multitasking machining with machine tools. Sinumerik Operate and the Sinumerik 840D sl CNC control combine several machining technologies – such as turning, milling and drilling, as well as workpiece and tool measuring – on one machine tool. This ensures the complete machining of highly complex workpieces. With its cross-technology, standardized and intuitive look-and-feel Sinumerik Operate supports the user in performing everyday tasks.

Sinumerik Operate Version 4.7 comprises among others extended setup and manual modes (JOG), which now interactively support the user when setting up milling-turning machines. There is also a new measuring function for approached turning tools, in which the setting screen automatically changes depending on the tool type to be measured. In addition, the workpiece measurement has been improved, now enabling the user to easily check and specify the workpiece zero on the component. In addition, Siemens has simplified the approach of turning tools in tool setup mode (TSM): When the user selects a turning tool, the machine automatically switches to turning mode.

The tool management has also been extended in Sinumerik Operate Version 4.7. The display shows transparently at a single glance all the tools for the technologies used on the multitasking machine. With the redefinition of a tool, turning tools and complex tools such as multitools are now represented as icons. This simplifies the operation and is an advantage, for example, during complete machining processes: The user can view the tool and magazine data for milling and turning tools in one display, including all details.

With new functions for flexible programming with programGuide and the workshop-compatible programming with ShopMill/ShopTurn, Siemens is simplifying multitasking machining. For example, the Cycle800 swivel cycle now combines turning and milling technologies in one user interface. The Cycle952 contour turning cycle permits 4-axis stock removal on multi-channel turning machines. In the programGuide turning cycles, a graphic contour calculator supports users during the data input and guides them through the parameter setting via a dialog. In ShopTurn, all approached tools are now programmable graphically and interactively, and milling is now also possible on turning machines.

The Sinumerik Operate user interface for the Sinumerik machine tool controls supports all machining procedures offered on multitasking machines across all technologies. For example, series manufacturers and jobshops can now machine workpieces efficiently and completely in one clamping. Apart from the most frequently used turning, milling and drilling technologies and the measurement functions, a multitude of additional production technologies can now be implemented on a customer-specific basis: These include grinding, gear hobbing and hob grinding, laser, electron-beam and plasma welding, eroding, laser and water-jet cutting, nibbling, honing and shaping.

Sinumerik Operate makes multitasking machining consistently possible for all technologies. The tool management supports the respective milling and turning tool types in all fields of application. NC programming with DIN/ISO and cycles is possible in programGuide or graphically in ShopMill/ShopTurn. In addition, Sinumerik Operate offers workpiece simulation, both for turning-milling and for milling-turning.

For further information on this topic, please see www.siemens.com/sinumerik

For further press information on innovations from Siemens at EMO 2015, please see www.siemens.com/press/emo2015

For further information about Siemens at the EMO 2015, please see

www.siemens.com/emo

Siemens AG (Berlin and Munich) is a leading international technology group. For more than 165 years, Siemens has stood for technological excellence, innovation, quality, reliability and international reach. The company operates in over 200 countries, focusing primarily on the fields of electrification, automation and digitisation. Siemens is one of the largest manufacturers of energyand fuel-efficient technologies worldwide. It is number one in offshore wind construction and is also a leading provider of gas and steam turbines for energy generation and transmission solutions. Siemens is a pioneer in the development of infrastructure solutions as well as automation, drive and software solutions for the industrial sector. The Group is also a leading provider of medical imaging equipment such as CMT and MRI systems. In addition, Siemens develops solutions in the field of lab diagnostics and clinical IT. In fiscal 2014, which ended on September 30, 2014, Siemens generated revenue from continuing operations of €71.9 billion and net income of €5.5 billion. At the end of September 2014, the company had around 343,000 employees worldwide.

Further information is available on the Internet at www.siemens.com

Reference Number: PR2015090365DFEN

Contact

Mr. Peter Jefimiec

Digital Factory Division

Siemens AG

Gleiwitzer Str. 555

90475 Nuremberg

Germany

Tel: +49 (911) 895-7975

peter.jefimiec@siemens.com