Enhancing Powder Quality with Virtual Granulation Simulations

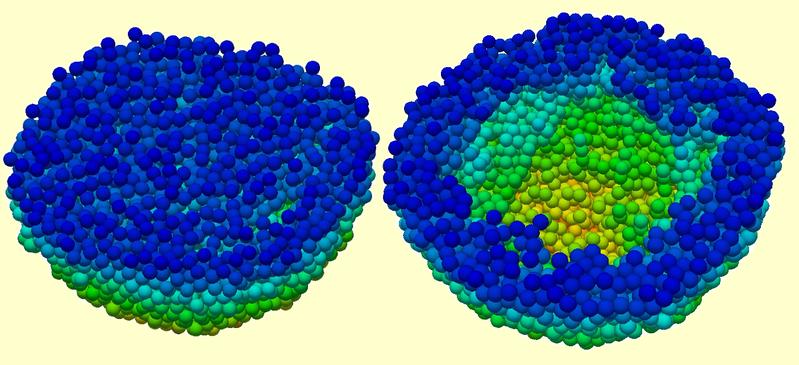

Spray dried granules: Depending on the choice of process and suspension parameters, the simulation can generate dense (left) or porous or hollow (right) granulate.

© Fraunhofer Institute for Mechanics of Materials IWM

Previously, it was unusual for granule and powder producers to use granulation simulations to improve their products. For new product development or process optimization, manufacturers relied on trial and error.

Spray drying is, however, influenced by many process parameters as well as the material behavior of the fluid and dissolved particles. Experts at the Fraunhofer IWM have now developed a new simulation method: coupled particle flow simulation shows the interaction between the particles and suspension. “The flow of the various particle sizes as well as their location in the liquid are incorporated“, explains Fraunhofer IWM simulation expert Thomas Breinlinger.

“For example, we can detect if there is an increase of smaller particles outside while the larger particles are more likely to be found inside or how they move in the liquid throughout the process.“ This new numerical simulation model combines long-established Fraunhofer IWM particle flow simulations, i.e., CFD (Computational Fluid Dynamics) and DEM (Discrete Element Method).

The spray drying simulation technology is already successfully being deployed with ceramic granules, but can also be implemented for powder and granulate in the pharmaceutical, biotechnology, nanotechnology and food industries. Additionally, manufacturers of drying systems benefit from the simulation by gaining a better grasp of the origin and structure of the granular materials.

Increased economic efficiency through simulations and modeling

Using the new simulation method, granulate manufacturers better understand how their product is created and what most affects granule quality. As a result, it becomes clear which of the modeled flow parameters are actually relevant for improving product quality or to aid in the resolution of specific problems.

By providing the possibility for targeted granulate and powder manufacturers to produce a special morphology, the process simulation and modeling can also aid in the reduction of development costs. In a project sponsored by the DFG (German Research Foundation), scientists at the Fraunhofer IWM have conducted simulations on various ceramic suspensions to discover their specific differences regarding the resulting granules.

“We have combined several primary particles in the suspension to be represented by a single particle in our simulation,” states Breinlinger, who goes on to say that the particles in the simulation have been slightly enlarged, to facilitate better and more predictable calculations and descriptions. “Depending on whether the primary particles in the suspension have agglomerated rather than dispersed, the particles in the simulation maintain different properties, which aid in mapping the interaction of the primary particles,” he explains.

This means that the influence of the interaction of microscopically small primary particles on the formation of granular materials can be directly described, without the need for further simulations. As a basis for his work, the Fraunhofer scientists rely on their many years of experience in materials modeling and simulation, in particle flow simulation, in the development of simulation codes and corresponding methods, as well as on the profound understanding of materials and material systems established at the Fraunhofer IWM.

Implementing the simulation to the technical process of spray drying

The materials specialists are now seeking an industrial partner with whom they can conduct and refine spray drying process simulations. Currently under consideration is the energy potential between particles in an approximated form as well as the calculation of a “smeared” suspension behavior. In the future they plan still further in-depth simulations of these parameters so as to validate concrete applications. “The tool already works very well and we look forward to continuing to refine and implement it for large scale commercial use” concludes Breinlinger.

http://www.en.iwm.fraunhofer.de/press-events-publications/details/id/1011/ – Press release online –

http://www.en.iwm.fraunhofer.de/business-units/manufacturing-processes/powder-te… – Fraunhofer IWM: Powder Technology, Fluid Dynamics –