TheiaX Launches Innovative Mapping for Sustainable Raw Materials

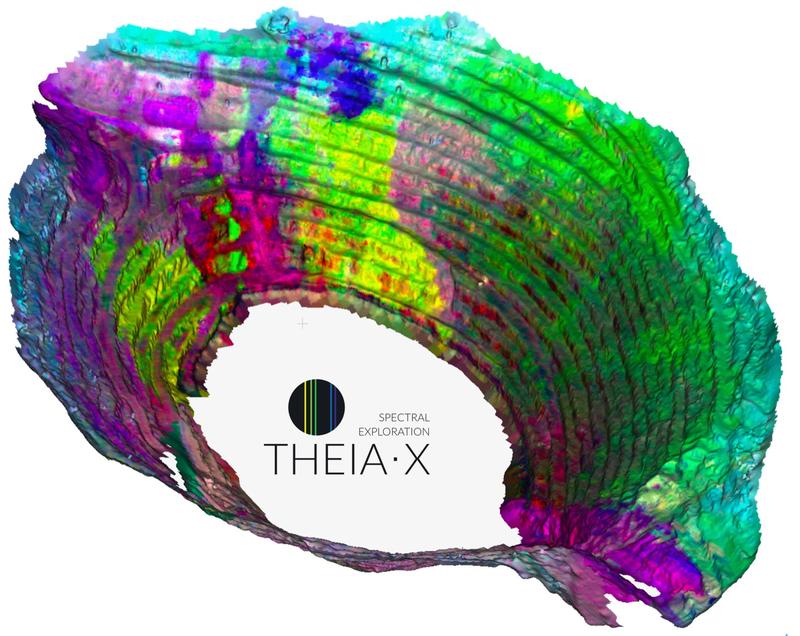

Integration of 3D outcrop and subsurface models with a hyperspectral imaging of the Corta Atalaya open pit to highlight lithological variations associated with differences in the abundance of AlOH-bearing minerals

Credit: TheiaX

Freiberg-based start-up TheiaX enters market with innovative mapping methods.

With the increasing demand for high-tech metals by the industry, mining faces complex challenges. The sustainable supply of raw materials requires energy-efficient and socially acceptable methods with low environmental impact. At the Helmholtz Institute Freiberg for Resource Technology (HIF) belonging to the Helmholtz-Zentrum Dresden-Rossendorf (HZDR), researchers have developed novel, digital mapping methods for sustainable raw material exploration and extraction over the past two years and brought them to market. The founding team of TheiaX is now offering these technologies to industry. The start-up is already the third spin-off of the Freiberg institute.

For some years now, the mining sector has also been paying more attention to sustainability. Novel exploration methods for assessing the subsurface play a decisive role here. Over the past two years, scientists at HIF have developed methods and technologies that make an environmentally friendly and socially acceptable analysis possible. “We have combined hyperspectral imaging technologies, that can record images of very many, closely spaced wavelengths, with self-developed machine learning algorithms and can thus produce precise models of the subsurface. These help mining companies in resource assessment, i.e. whether mineral extraction is economically viable,” explains Dr. Richard Gloaguen, Head of Exploration Department at HIF and founding partner at TheiaX.

TheiaX offers efficient, non-invasive mineral exploration using innovative sensors. The sensors can be installed on various platforms, for example on drones, and provide precise images of the raw material deposits in the ground from a distance. High-tech metals in particular can thus be tracked down in an environmentally friendly way. In addition, TheiaX uses the potential of artificial intelligence and virtual reality to provide an economical, fast, non-invasive decision-making tool for raw material exploration and extraction. To this end, the Freiberg scientists have developed novel digital mapping processes.

Novel mapping with artificial intelligence

These provide digital twins that serve as a reliable basis for both structural and lithological (mineral composition of the rock) mapping and environmental monitoring. “With our imaging technique, outcrops, mine surfaces and drill cores can be visualized with a better spatial understanding of mineralogical variability, which in turn influences decision-making processes. The technologies developed minimize environmental impact, strengthen community acceptance and at the same time improve existing exploration technologies,” Gloaguen describes the methods.

For industry, the technologies offer the advantage of faster and more precise characterization of raw materials without major interference with nature. “So far, we have already been able to realize projects for the mining industry in Greenland, Bulgaria, Greece, the Czech Republic and Germany with our customized solutions. The demand shows clearly that we are filling a gap in the market with our services,” Christian Christesen, Managing Director and Business Developer of TheiaX, is satisfied.

Transferring research results to industry

The founding of the company was preceded by several years of research in which the Helmholtz Association within the framework of the Helmholtz Enterprise program and the HZDR Innovation Fund have funded the technological developments. The programs support scientists in bringing their research into application and testing it until it reaches the market readiness level. TheiaX was also accompanied by HZDR Innovation GmbH (HZDRI), a commercial transfer company of the HZDR that supports promising research results in their transfer to industry. “In the past incubation phase, the TheiaX team has proven that its newly developed technologies meet a current market need for fast and accurate characterization of raw materials. The team, consisting of five nationalities, has also acquired the necessary entrepreneurial skills in the past months. The first industrial projects have been successfully completed. We are pleased that TheiaX will be the second promising spin-off of the HZDR in 2021 and wish the spin-off every success,” says Dr. Björn Wolf, Managing Director of HZDRI.

The research group around Richard Gloaguen has given the new company the name TheiaX GmbH. The titan Theia is the Greek goddess of sight and the brilliant blue sky and is said to has given to have given precious stones and precious metals their brilliance and intrinsic value. The X in the name stands for exploration. The exploration of raw materials from afar using natural light is therefore also reflected in the company name.

Wissenschaftliche Ansprechpartner:

Dr. Richard Gloaguen | Department Head Exploration

Helmholtz Institute Freiberg for Resource Technology at HZDR

Phone: +49 351 260 4424 | Email: r.gloaguen@hzdr.de

Christian Christensen | Managing Director

TheiaX GmbH

Phone: +49 351 260 4431 | Email: services@theiax.de

Dr. Björn Wolf | Managing Director

HZDR Innovation GmbH

Phone: +49 351 260 3348 | Email: info@hzdri.de

Originalpublikation:

https://www.hzdr.de/db/Cms?pOid=64861&pNid=2423