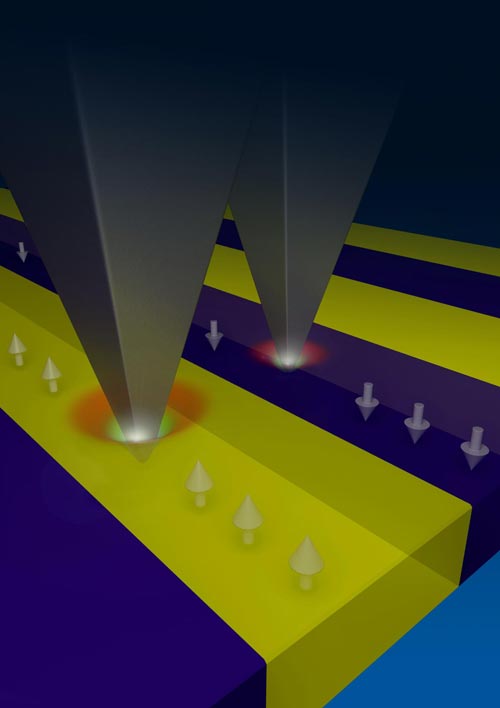

This is an artistic representation of the new material.

Credit: ICN2

PhD student Kumara Cordero-Edwards is the lead author of this work, carried out in collaboration with researchers from the Autonomous University of Barcelona (UAB). Highlighted in the journal's frontispiece, the article outlines how the indentation toughness of polar crystals can be manipulated in such a way that they become easier or harder to dent from a given direction.

This is the result of the interaction between the localised flexoelectric polarisation caused by the mechanical stress gradient of the indentation, on the one hand, and the piezoelectric polarisation inherent in polar crystals, on the other. If the two polarisations run parallel, overall polarisation is going to be very strong.

This carries a higher energy cost, which makes the act of indentation itself more difficult. But if we turn the material over, the flexoelectric effect of the knock will be acting in the opposite direction to the spontaneous piezoelectric effect, making total polarisation weaker and indentation correspondingly easier.

But the observations of our researchers did not end there. In the case of a particular subset of piezoelectric materials, ferroelectrics, it is not even necessary to physically turn the material upside down; we can simply apply an external voltage to flip its polar axis.

These effects were observed not only for forceful indentations and/or perforations, but also for the gentler, non-destructive pressures delivered by the tip of an atomic force microscope.

Aside from potential applications in smart coatings with switchable toughness, these effects could one day be used as a means of reading ferroelectric memories by touch alone.