Flexible, highly sensitive motion device created by extrusion printing

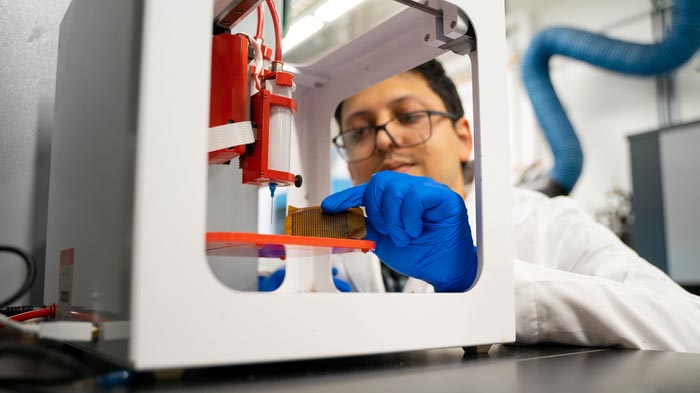

UBC Okanagan doctoral student Ahmadreza Ghaffarkhah uses a 3D printer to create small and highly-accurate sensors that can be integrated into clothing and equipment.

Credit: UBC Okanagan photo

UBCO researchers change the game when it comes to activity tracking.

The creation of high-resolution extrusion printing—think 3D printing but with ink that conducts electricity—has enabled UBC researchers to explore the potential of wearable human motion devices.

Wearable technology—smartwatches, heart monitors, sleep aid devices, even step counters—have become part of everyday life. And researchers with UBC Okanagan’s Nanomaterials and Polymer Nanocomposites Laboratory, have created even smaller, lighter and highly-accurate sensors that can be integrated into clothing and equipment.

In collaboration with Drexel University and the University of Toronto, the UBCO research team is exploring a high-resolution extrusion printing approach to develop tiny devices with dual functionality—electromagnetic interference (EMI) shields and a body motion sensor.

Tiny and lightweight, these EMI shields can have applications in the health care, aerospace and automotive industries, explains Dr. Mohammad Arjmand, Assistant Professor and Canada Research Chair in Advanced Materials and Polymer Engineering at UBC Okanagan’s School of Engineering.

Using a two-dimensional inorganic nanomaterial called MXene, alongside a conductive polymer, Dr. Arjmand’s team has customized a conductive ink with a number of properties that make it easier to adapt into wearable technologies.

“Advanced or smart materials that provide electrical conductivity and flexibility are highly sought-after,” he says. “Extrusion printing of these conductive materials will allow for macro-scale patterning, meaning we can produce different shapes or geometries, and the product will have outstanding architecture flexibility.”

Currently, manufacturing technologies of these functional materials are mostly limited to laminated and unsophisticated structures that don’t enable the integration of monitoring technologies, explains doctoral student Ahmadreza Ghaffarkhah.

“These printed structures can be seeded with micro-cracks to develop highly sensitive sensors. Tiny cracks in their structures are used to track small vibrations in their surroundings,” says Ghaffarkhah. “These vibrations can monitor a multitude of human activities, including breathing, facial movements, talking as well as the contraction and relaxation of a muscle.”

By going back to the drawing board, the UBCO researchers were able to address a major challenge encountered by extrusion printing. Previously, the technology didn’t allow for high-enough printing resolution, so it was difficult to manufacture highly precise structures.

“Compared to conventional manufacturing technologies, extrusion printing offers customization, reduction in materials waste, and rapid production, while opening up numerous opportunities for wearable and smart electronics,” explains Dr. Arjmand. “As extrusion printing techniques improve, it is opening the door to many unique innovations.”

The researchers continue to investigate additional applications for extrusion printing inks that go beyond EMI shields and wearable electronics.

The research was published in Carbon, with financial support from a Natural Sciences and Engineering Research Council of Canada Alliance Grant and Zentek Limited.

Journal: Carbon

DOI: 10.1016/j.carbon.2022.02.003

Method of Research: Meta-analysis

Subject of Research: Not applicable

Article Title: High-resolution extrusion printing of Ti3C2-based inks for wearable human motion monitoring and electromagnetic interference shielding

Article Publication Date: 22-May-2022

Media Contact

Patty Wellborn

University of British Columbia Okanagan campus

patty.wellborn@ubc.ca

Cell: 250-317-0293

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…