A team of scientists working at the U.S. Department of Energy's Princeton Plasma Physics Laboratory (PPPL) has found that increasing the amount of lithium coating in the wall of an experimental fusion reactor greatly improves the ability of experimentalists to contain the hot, ionized gas known as plasma. Adding more lithium also enhances certain plasma properties aiding the reaction, the researchers found.

“The lesson here for confining plasma is surprising and simple: When you use more and more lithium, the plasma confinement gets better and better,” said Rajesh Maingi, a physicist from the Oak Ridge National Laboratory (ORNL) who is on long-term assignment to PPPL. “This is not what we expected to see. We thought the effect would taper off at some point. But it doesn't. When it comes to fusion plasmas, it's “the more, the merrier.'”

If plasma energy confinement is improved, a fusion reactor can, in principle, be made smaller and, therefore, cheaper. Energy confinement is a measure of how long (in seconds) power that is injected into the plasma stays in the plasma before leaking out to the walls.

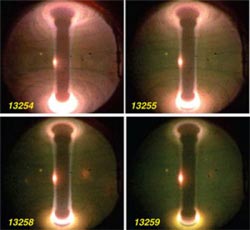

Spraying lithium onto the inner surface of an experimental fusion device at PPPL known as the National Spherical Torus Experiment (NSTX) improves several other conditions for fusion, the experimenters found. The lithium reduced recycling—the problematic ricocheting of particles into the vessel wall and back into the plasma (Figure 1). Recycling leads to cooling, contamination, and, ultimately, dissipation of the energy of the plasma. In addition to reducing recycling, the lithium coating—and enhanced coatings based on it—also enhanced the reaction by decreasing chaotic instabilities both at the plasma's edge, and also on a larger scale.

The experiment's results indicate that fusion machine designers may be able to reduce the size and the level of heating in future devices designed to use lithium coating technologies.

In addition to Maingi, other researchers on the effort included: Stanley Kaye and Charles Skinner from PPPL, D.P. Boyle from Princeton University; and J.M. Canik from ORNL. This work recently appeared in Physical Review Letters 107 (2011) 145004.

The work is being presented at the 53rd Annual Meeting of the American Physical Society Division of Plasma Physics, being held Nov. 14-18, in Salt Lake City, Utah.

Abstracts:

BO4.00004 The continuous improvement of H-mode discharge performance with progressively increasing lithium coatings in NSTX

Session BO4: NSTX and Spherical Torus,

Ballroom E, Monday, November 16, 2011, 10:06AM:18AM