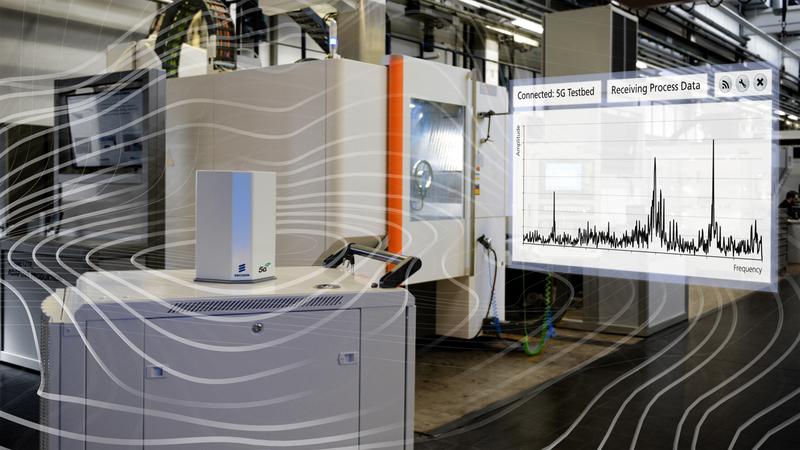

The Fraunhofer IPT has joined forces with international partners to network industrial production wirelessly with 5G in order to test its potential for industrial environments.

Foto: Fraunhofer IPT

In the research project “5G-SMART: 5G for smart manufacturing”, funded by the European Union for the next two and a half years, the partners are building 5G networks in actual manufacturing environments to demonstrate, test, and further develop the potential of 5G in production.

The consortium is testing the interplay between 5G and state-of-the-art manufacturing equipment such as remote-controlled industrial robotics, wireless process monitoring in manufacturing, and mobile robotics.

This is taking place throughout Europe; in an Ericsson factory in Sweden, in the machine hall at the Fraunhofer IPT in Aachen, and in a Bosch semiconductor factory in Reutlingen.

Manufacturing companies and mobile network suppliers jointly define requirements for 5G networks in production environments

The new mobile radio standard 5G is suitable for making manufacturing processes more flexible and adaptive than before, improving the quality of components, reducing costs and thus increasing productivity.

The requirements to be met by 5G networks to ensure that they are tailored to the needs of the manufacturing industry are defined by the application partners together with mobile network suppliers. These include, for example, the integration of 5G in communication standards such as time-sensitive networking (TSN) and cloud platforms, which enable a flexible machine control alongside low latency and high reliability.

5G-capable sensor technology as a building block for networked, adaptive production

The Fraunhofer IPT is collaborating with its project partners to develop new 5G-capable, industrially usable sensors and radio modules and is testing them in its own machines and equipment on the basis of specific production tasks. This should make it possible to record process data with latencies of just a few milliseconds, evaluate them in real time, and thus optimize process monitoring throughout the entire industrial process chain.

This enables the engineers to detect process deviations and machine states in good time and to react swiftly via control commands to the machine in order to ensure that components are produced in the required quality and production times. For this, the Fraunhofer IPT uses its existing 5G test environment, which was installed by the Swedish mobile network supplier Ericsson in the machine hall of the institute in Aachen last year.

Integrated sensors, wirelessly connected to cloud-based analysis tools via 5G mobile radio connections, will help manufacturing companies of any size and sector to collect valuable data and process it into information.

In the course of their research project, the partners will investigate which concrete business models 5G offers for manufacturing companies, suppliers, and mobile network operators in order to further accelerate the introduction of 5G in production environments.

Project consortium:

– Ericsson AB, Sweden (Coordinator)

– ABB AB, Sweden

– Budapest University of Technology and Economics, Hungary

– Cumucore Oy, Finland

– Ericsson GmbH, Germany

– Ericsson Magyarorszag Kommunikacios Rendszerek K.F.T., Hungary

– Fraunhofer Institute for Production technology IPT, Germany

– Marposs Monitoring Solutions GmbH, Germany

– Marposs SpA, Italy

– Orange SA, France

– Robert Bosch GmbH, Germany

– T-Systems Magyarorszag Zartkoruen Mukodo Reszevytarsasag, Hungary

– u-blox AG, Switzerland

– u-blox Melbourn Ltd., UK

– Universität Lund, Sweden

– Universitat Politecnica de Valencia, Spain

This research project is funded by the Horizon 2020 research and innovation program of the European Union under grant agreement No. 857008.

Dipl.-Phys. Niels König

Fraunhofer Institute for Production Technology IPT

Steinbachstr. 17

52074 Aachen, Germany

Phone +49 241 8904-113

niels.koenig@ipt.fraunhofer.de

https://www.ipt.fraunhofer.de/en/Press/Pressreleases/20190823-5G-is-smartening-u…