Reprogramming Macroscopic Self-Assembly with Dynamic Boundaries

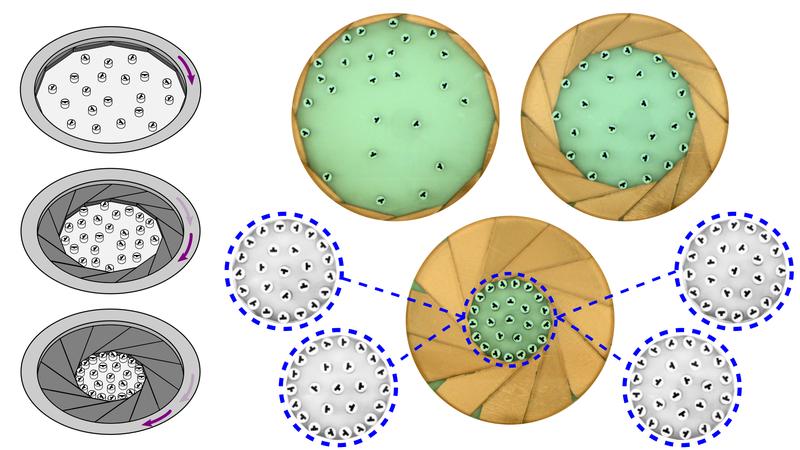

Figure: Dynamically moving hard boundaries confine mobile magnetic particles into reprogrammable 2D self-assembled patterns

Graphic: https://pi.is.mpg.de/uploads/ckeditor/pictures/1145/content_Reprogramming_of_macroscopic_self-assembly_with_dynamic_boundaries.png

Self-assembly is an autonomous process where complex and functional structures are created in a bottom-up manner by the organization of a large set of components.

Each component locally interacts with the others to create patterns, often with an unknown outcome: in the end, the patterns do not necessarily have a pre-conceived design.

Scientists at the Physical Intelligence Department of the Max Planck Institute for Intelligent Systems (MPI-IS) in Stuttgart aim to understand the underlying process of self-assembly.

As this process continuously takes place both in living and non-living systems in a multitude of scales, their motivation is to understand the rules and dynamics of self-assembly – findings that not only provide valuable insights into fundamental physics, but could enable the design of functional materials or self-assembled miniature robots.

One recent project is “Statistical reprogramming of macroscopic self-assembly with dynamic boundaries”, a paper that was published in the Proceedings of the National Academy of Sciences (PNAS) on 12th May 2020. “We are interested in gaining the ability to control the self-assembly process to elucidate fundamental physics, and also to enable the fabrication of novel material systems and design of robotic systems,” says Dr. Utku Culha, who is the first author of the publication.

Culha is a postdoctoral researcher in the Physical Intelligence Department and an expert in Soft Robotics and Bioinspired Mechanisms. “In our work, we propose a control approach that allows the programming of self-assembled patterns in a repeatable and reversible way,” Dr. Culha further explains this fundamental research.

“What we did is to confine magnetically repulsive millimeter-scale particles inside an orbitally shaken platform that provides a constant source of kinetic energy for the particles,” Dr. Zoey S. Davidson adds. He is one of the co-authors and like Dr. Culha a postdoctoral researcher. He specializes in Experimental Condensed Matter Physics. “Our confinement system compresses the freely moving magnetic particles via moving hard boundaries and traps them into diverse two-dimensional patterns.”

“Building upon our previous works, here we moved from the curiosity of exploting boundaries to steer self-assembly processes. We incidentally confirmed that mechanical shaking is functionally analogous to temperature at the Brownian motion, and came up with what can be also considered as a macroscopic simulator of colloidal self-assembly processes” adds Dr. Massimo Mastrangeli, paper co-author, MPI-IS alumnus and currently assistant professor at Delft University of Technology.

The team showed that they can statistically program these two-dimensional patterns by controlling the rate of particle compression. Moreover, their programming approach is reversible; meaning that after selecting one pattern, the system can be restored to its original state and reprogrammed to choose another. Their approach also shows the programming of material properties, as these patterns have unique elasticity and magnetic clutching properties.

They show the correlation between confinement dynamics and resulting self-assembled structures, and also demonstrate the tuning of their mechanical and magnetic properties. “This system bears the prospect of designing granular materials in a multitude of physical scales as our approach is scalable to different particle types, sizes, and counts,” Culha says.

“By using our dynamic boundary regulation approach, in the future, we would like to use small-scale mobile robot swarms instead of particles and pave the way for a completely new approach for reconfigurable robotic assembly systems,” Metin Sitti envisions. He is the Director of the Physical Intelligence Department at MPI-IS and the senior author of the publication.

About us:

Dr. Utku Culha is an expert in Soft Robotics and Bioinspired Mechanisms with a MSc degree in Computer Engineering from Bilkent University in Turkey and a Ph.D. degree in Mechanical and Process Engineering from ETH Zürich. “I want to build magnetic miniature robots using soft and deformable materials”, Culha says. “I want to exploit their deformable and magnetic nature to actively change their shape in order to generate different functions. For example, the robot should swim when it is deformed like a snake, or it should grasp an object when it deforms like a pincer. But there are more possibilities, that is why I want to explore their designs and functions further using machine-learning methods.”

Dr. Zoey Davidson is an expert in Experimental Condensed Matter Physics and joined the MPI-IS from the University of Pennsylvania in Philadelphia, where he did his Ph.D. in soft matter physics. “I am currently working on transferring the latest developments in soft matter physics to applications in soft robotics. In particular, I am developing micro actuators, artificial muscle, from liquid crystal elastomers to enable new capabilities in the field of microrobotics. Liquid crystal elastomers allow for controlled programmable elastic anisotropy at the micron scale, which will be used in new methods of micro manipulation and locomotion.”

Dr. Massimo Mastrangeli is a tenure-track assistant professor at Delft University of Technology, where he is developing silicon/polymer-based organ-on-chip and nanoparticle-based devices. He held a research appointment at MPI-IS for soft microrobotics and granular matter, Université Libre de Bruxelles for micromechanics and capillary micromanipulation, EPFL for micro/nanofabrication and distributed robotics, and IMEC Belgium for fluidic microsystems integration and microelectronic packaging. He holds a B.Sc. and M.Sc. degree in Electronic Engineering from University of Pisa (Italy) and a Ph.D. degree in Materials Engineering from University of Leuven (Belgium).

Director Dr. Metin Sitti heads the Physical Intelligence Department at the Max Planck Institute for Intelligent Systems, based in Stuttgart. He received his BSc and MSc degrees in electrical and electronics engineering from Bogazici University in Istanbul in 1992 and 1994, respectively, and his PhD degree in electrical engineering from the University of Tokyo in 1999. He was a research scientist at the University of California at Berkeley during 1999-2002. During 2002-2016, he was a Professor in the Department of Mechanical Engineering and Robotics Institute at Carnegie Mellon University in Pittsburgh, USA. Since 2014, he is a Director at the Max Planck Institute for Intelligent Systems.

Sitti and his team aim to understand the principles of design, locomotion, perception, learning, and control of small-scale mobile robots made of smart and soft materials. The intelligence of such robots mainly comes from their physical design, material, adaptation, and self-organization more than to their computational intelligence. Such physical intelligence methods are essential for small-scale milli- and micro-robots especially due to their inherently limited on-board computation, actuation, powering, perception, and control capabilities. Sitti envisions his novel small-scale robotic systems to be applied in healthcare or environmental remediation to name a few.

Metin Sitti

Director

Physical Intelligence Department

Max Planck Institute for Intelligent Systems

sitti@is.mpg.de

https://www.pnas.org/content/early/2020/05/06/2001272117

https://is.mpg.de/news/reprogramming-of-macroscopic-self-assembly-with-dynamic-b…