LED instead of laser or electron beam: New technology revolutionizes 3D metal printing

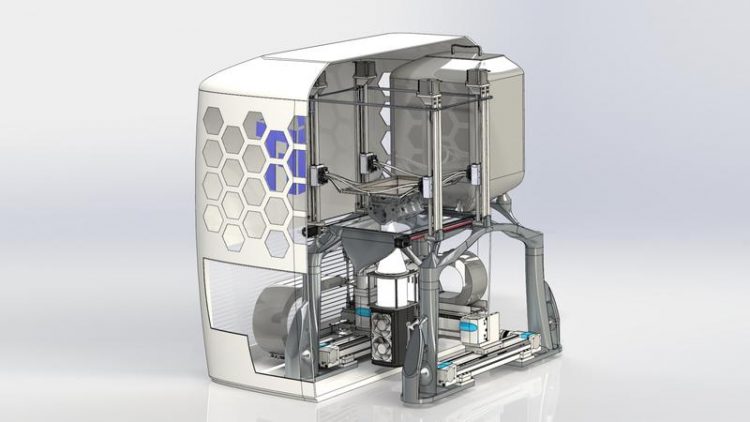

The 3D printer developed at TU Graz melts metal powder using high-performance LED light sources and then processes it into components in additive manufacturing. Photo: TU Graz

Selective LED-based melting (SLEDM) – i.e. the targeted melting of metal powder using high-power LED light sources – is the name of the new technology that a team led by Franz Haas, head of the Institute of Production Engineering at TU Graz, has developed for 3D metal printing and has now applied for a patent.

The technology is similar to selective laser melting (SLM) and electron beam melting (EBM), in which metal powder is melted by means of a laser or electron beam and built up into a component layer by layer. However, SLEDM solves two central problems of these powder bed-based manufacturing processes: the time-consuming production of large-volume metal components and the time-consuming manual post-processing.

Reduced production time

Unlike the SLM or EBM processes, the SLEDM process uses a high-power LED beam to melt the metal powder. The light-emitting diodes used for this purpose were specially adapted by the west Styrian lighting specialist Preworks and equipped with a complex lens system by which the diameter of the LED focus can be easily changed between 0.05 and 20 millimetres during the melting process.

This enables the melting of larger volumes per unit of time without having to dispense with filigree internal structures, thus reducing the production time of components for fuel cell or medical technology, for example, by a factor of 20 on average.

Tedious reworking is no longer necessary

This technology is combined with a newly designed production plant which – in contrast to other metal melting plants – adds the component from top to bottom. The component is thus exposed, the required amount of powder is reduced to a minimum and the necessary post-processing can be carried out during the printing process.

“The time-consuming, usually manual reworking that is necessary with current methods, for example, smoothing rough surfaces and removing supporting structures, is no longer necessary and saves further valuable time,” says Haas.

Fields of application and further plans

A demonstrator of the SLEDM process is already being considered in the K-Project CAMed of the Medical University of Graz, where the first laboratory for medical 3D printing was opened in October 2019. The process will be used to produce bioresorbable metal implants, i.e. preferably screws made of magnesium alloys that are used for bone fractures.

These implants dissolve in the body after the fracture site has grown together. A second operation, which is often very stressful for people, is therefore no longer necessary.

Thanks to SLEDM, the production of such implants would be possible directly in the operating theatre, because “an LED light is naturally less dangerous for the operation than a powerful laser source,” says Haas.

The second focus is on sustainable mobility, namely the production of components such as bipolar plates for fuel cells or components for battery systems. “We want to make additive manufacturing using SLEDM economically viable for e-mobility and position SLEDM in this field of research at an early stage,” says Haas, who will produce a marketable prototype of this 3D metal printer – “made by TU Graz” – in the next development step: a further innovation in the university environment.

The SLEDM process was developed in the FoE “Mobility & Production”, one of five scientific research foci of Graz University of Technology.

At Graz University of Technology, various research groups are working on additive manufacturing processes. Information on this topic can be found in our TU Graz research e-paper: The 3D Revolution (https://epaper.tugraz.at/paper/39/1)

The Institute of Production Engineering and the Institute of Materials Science, Joining and Forming are currently working intensively on the set-up of their own additive manufacturing laboratory, the AddLab@tugraz. In Planet Research, Franz Haas tells more about the project (with video): https://www.tugraz.at/en/tu-graz/services/news-stories/planet-research/singlevie…

Contact:

Franz HAAS

Univ.-Prof. Dipl.-Ing. Dr.techn.

TU Graz | Institute of Production Engineering

Tel.: +43 316 873 – 7170

franz.haas@tugraz.at

http://www.ift.tugraz.at

Franz HAAS

Univ.-Prof. Dipl.-Ing. Dr.techn.

TU Graz | Institut für Fertigungstechnik

Tel.: +43 316 873 – 7170

franz.haas@tugraz.at

ift.tugraz.at

https://www.preworks.at/index.php/en/ (lighting specialist Preworks)

https://www.medunigraz.at/en/camed/about-camed/ (K-Project CAMed of the Medical University of Graz)

https://www.tugraz.at/en/research/forschungsschwerpunkte-5-fields-of-expertise/m… (Field of Expertise “Mobility & Production)

Media Contact

All latest news from the category: Machine Engineering

Machine engineering is one of Germany’s key industries. The importance of this segment has led to the creation of new university degree programs in fields such as production and logistics, process engineering, vehicle/automotive engineering, production engineering and aerospace engineering among others.

innovations-report offers informative reports and articles covering technologies such as automation, motion, power train, energy, conveyor, plastics, lightweight construction, logistics/warehousing, measurement systems, machine tools and control engineering.

Newest articles

A flexible and efficient DC power converter for sustainable-energy microgrids

A new DC-DC power converter is superior to previous designs and paves the way for more efficient, reliable and sustainable energy storage and conversion solutions. The Kobe University development can…

Technical Trials for Easing the (Cosmological) Tension

A new study sorts through models attempting to solve one of the major challenges of contemporary cosmic science, the measurement of its expansion. Thanks to the dizzying growth of cosmic…

Peptides on Interstellar Ice

A research team led by Dr Serge Krasnokutski from the Astrophysics Laboratory at the Max Planck Institute for Astronomy at the University of Jena had already demonstrated that simple peptides…