Budget-Friendly Retrofit for Wire-Based Laser Deposition Welding

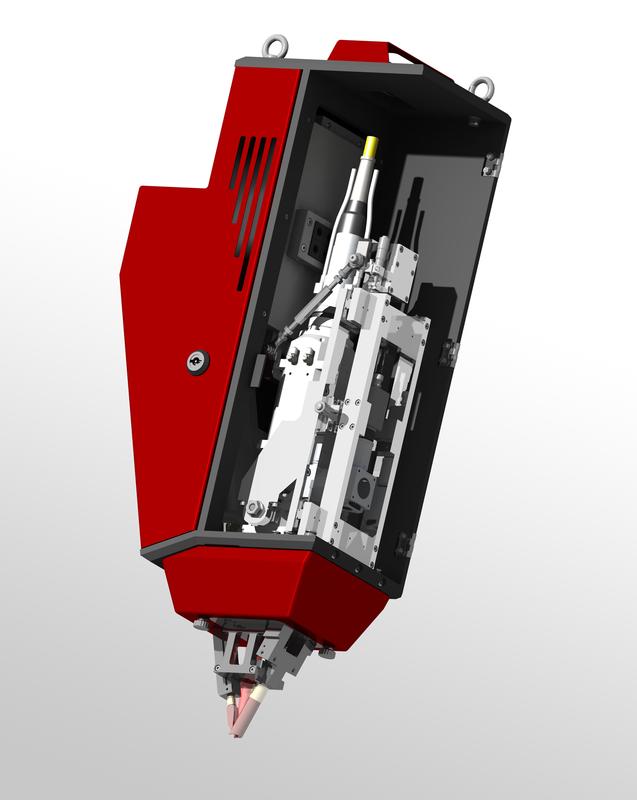

Processing head "LMD-W-20-L" for wire-based laser deposition welding.

Graphic: Fraunhofer IPT

3D powder bed printing is currently the most well-known additive manufacturing process for filigree and complex metallic parts. A laser fuses the powdered material with pinpoint accuracy in a closed unit. However, there are two other less well-known additive processes which are particularly suitable for repairing or modifying larger-scale parts: powder-based and wire-fed laser deposition welding.

Deposition welding performed using local infeed of firm, wire material is significantly more material-efficient and environmentally-friendly than powder-based laser deposition welding in which the material flows in the form of tiny particles at high pressure out of nozzle and onto the component to be melted there by the laser.

Due to the easy to handle additive material, wire-feed deposition welding, also known as Laser Metal Deposition – Wire (or LMD-W) is highly suitable for integration in existing production lines. However, the process is considerably more complex to control and therefore more fault-prone than powder-based deposition welding.

Consequently, it has previously been used mainly for rough pre-machining operations. The “LMD-W-20-L” laser machining head, developed by the Fraunhofer IPT in Aachen, is a retrofit solution, whose sturdy construction and smart sensor system equip it for combination even with industrial robot systems in the medium term.

The modular LMD head integrating conventional process chains

The cost-effective welding head works with commercially available laser optics and and does not require complex custom-made beam guidance systems. In future it will be possible to record typical faults as they arise in the course of an on-going process, permitting the causes to be analyzed during the operation and to be offset by the control system.

Lateral wire infeed at a steep angle of 20 degrees to the optical axis ensures stable processes with high fusing efficiency. The range of wire materials available already includes various types of steel, nickel and titanium-based alloys along with numerous special purpose materials. The Fraunhofer IPT is currently exploring the suitability of other alloys as part of a number of research projects.

LMD-W – Additive process with 100 percent material efficiency

The stand-out characteristic of wire-based laser deposition welding is the quasi 100 percent material efficiency since the material fed in is melted completely and applied layer-by-layer to the surface of the part.

Given the CAM support required and multi-axis process control, additional functional elements can be added to existing parts to produce a hybrid construction and permitting repairs or modifications to be undertaken. A wide range of wire based additional materials can be processed not only very cost-efficiently but also in near-net-shape ensuring that the parts turned out are of premium quality.

This press release and a printable photo are also available on the internet: http://s.fhg.de/LMD-W-20-L

Stefan Gräfe M.Eng.

Fraunhofer Institute for Production Technology IPT

Steinbachstraße 17

52074 Aachen, Germany

www.ipt.fraunhofer.de/en

stefan.graefe@ipt.fraunhofer.de