Mimicking body's circulatory AC could keep airplanes, cars and computers cooler

Researchers from Drexel University have created a program that optimizes the microvascular configuration of materials that could be used to cool technology that runs hot -- like computers and automobiles.

Credit: Drexel University

The complex network of veins that keeps us cool during the heat of summer has inspired engineers to create novel thermal management systems. But replicating the circulatory system, in form or function, has been no easy task.

Recently, a team of researchers from Drexel University and North Carolina State University have created a computational platform that could be the key to mimicking the body's evolutionary optimized cooling system. Microvasculature

In a study published in the International Journal of Heat and Mass Transfer, Ahmad Najafi, PhD, a professor in Drexel's College of Engineering, and his faculty collaborator, Jason Patrick, PhD, from North Carolina State University, report on how a computational technique they developed can quickly produce designs for 3D printing carbon-fiber composite materials with an internal vasculature optimized for active-cooling.

“When you get hot, the body sends a signal to the circulatory system to pump more blood to the surface of the skin – this is why we sometimes get red in the face” Najafi said.

“This is a natural method for dissipating heat that works so well, scientists and engineers have been trying for years to replicate in mechanical cooling systems, like the ones that keep cars and computers from overheating.”

Najafi and Patrick's latest paper describes an integrated platform to design and create bioinspired microvascular composites that can do just that.

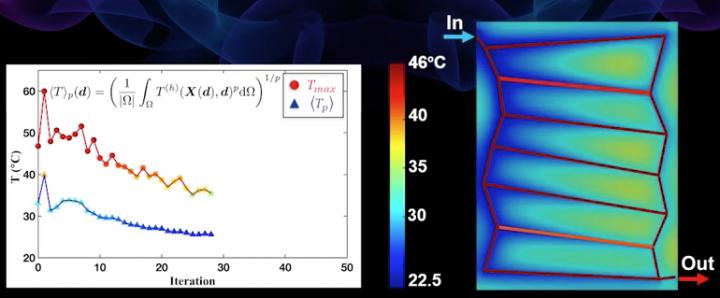

In minutes, their computer program, coined HyTopS, which is short for hybrid topology/shape optimization, can produce a schematic for a vascular network with the ideal shape, size and distribution of micro-vessels to actively cool a material via liquid circulation – a trick that took Mother Nature more than a few evolutionary cycles to perfect.

Microvascular fiber-composites are currently being developed to cool everything from electric vehicles to next generation aircraft, where increasingly higher performance is turning up the heat they generate.

“These modern materials could revolutionize everything from hypersonic space vehicles to battery packaging in electric cars and even supercomputer cooling systems. As things move faster, and energy output and computing power continue to increase, an enormous amount of heat is generated that requires new approaches to cooling,” Patrick said.

“Inspired by circulatory systems in living organisms, internal micro-vasculature provides an effective means to thermal regulation in synthetic materials.”

This branch of bioinspired-based research has only been around for a decade or so, but the results it has generated are already quite promising, according to Najafi/Patrick who started their academic careers at the University of Illinois Urbana-Champaign developing microvascular materials for self-healing, active cooling and beyond.

Part of their recent research thrust is to replace more traditional metallic systems that transfer heat via water or air. While it's been a reliable solution, anyone who has carried an air conditioner window unit will surely understand why a different cooling system would be an improvement for any vehicle or component that is trying to cut weight.

“Microvascular composites offer many advantages over existing liquid and air-cooling systems, primarily, they are much lighter with comparable strength, but they are also very durable – which is important if you consider the widespread effect of corrosion on metallic components,” Najafi sad. “And if you consider these among other factors, it's easy to see why they are being sought in aerospace, automotive and energy sectors.”

To put their optimization method to the test, the researchers designed and built a microvascular carbon-fiber composite using 3D printing and tested its cooling abilities against a reference design from prior studies. After heating the carbon-composites to a maximum temperature, liquid coolant (similar to the one in your car) was pumped through each vascular network to begin the cooling process.

The HyTopS-optimized carbon-composite was not only cooler, but more uniform in terms of surface temperature distribution, and was able to cool down faster than the reference design.

In addition to superior performance of the optimized material, the advantage the HyTopS method is that it automatically calculates the impact of changes to the diameter and arrangement of the channels, as well as how they are connected to one another. It takes into consideration the material makeup and overall geometry of the system being cooled and corresponding heat transfer characteristics. And it factors in parameters related to the manufacturing process, so the final design is a realistic microvascular material that can be made by 3D printing or other accessible fabrication approaches.

“It's nearly impossible to reproduce the entire complexity of natural microvascular, but our program allows for a great deal of optimization input and considers manufacturing parameters to ensure the design can actually be constructed,” Najafi said.

The collaborative team intends to use the HyTopS method to explore other intriguing and interdisciplinary aspects of microvascular composites, including structural mechanics and electromagnetics.

###

This work was funded by Drexel University and the Air Force Office of Scientific Research. In addition to Najafi and Patrick, Reza Pejman, from Drexel, and Sherif H. Aboubakr, William H. Martin and Urmi Devi, from North Carolina State University; and Marcus Hwai Tik Tan from the University of Illinois Urbana-Champaign also contributed to this research.

![[Figure 1] Schematic of next-generation CNT-PANI composite fiber supercapacitor and comparison graph with recent results](https://www.innovations-report.com/wp-content/uploads/2025/05/KIST_leads_next-generation_energy_storage_technolo_1746783279-e1746784635527-362x245.jpg)