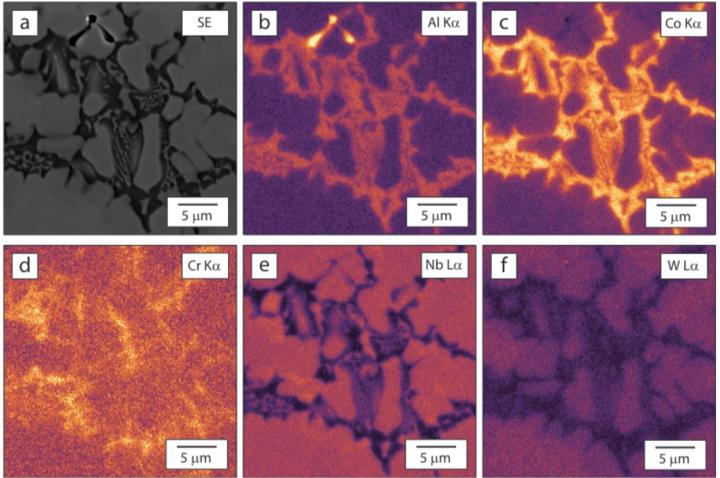

An X-ray energy-dispersive spectroscopy (EDS) map of the as-cast microstructure of a hard alloy predicted from Lehigh University researchers' analysis. Lettered panels are X-ray intensity maps associated with different elements comprising the alloy that permit deduction of the spatial distributions of these elements.

Credit: Lehigh University

A new method of discovering materials using data analytics and electron microscopy has found a new class of extremely hard alloys. Such materials could potentially withstand severe impact from projectiles, thereby providing better protection of soldiers in combat.

Researchers from Lehigh University describe the method and findings in an article, “Materials Informatics For the Screening of Multi-Principal Elements and High-Entropy Alloys,” that appears today in Nature Communications.

“We used materials informatics – the application of the methods of data science to materials problems – to predict a class of materials that have superior mechanical properties,” said primary author Jeffrey M. Rickman, professor of materials science and engineering and physics and Class of '61 Professor at Lehigh University.

Researchers also used experimental tools, such as electron microscopy, to gain insight into the physical mechanisms that led to the observed behavior in the class of materials known as high-entropy alloys (HEAs).

High-entropy alloys contain many different elements that, when combined, may result in systems having beneficial and sometimes unexpected thermal and mechanical properties. For that reason, they are currently the subject of intense research.

“We thought that the techniques that we have developed would be useful in identifying promising HEAs,” Rickman said. “However, we found alloys that had hardness values that exceeded our initial expectations. Their hardness values are about a factor of 2 better than other, more typical high-entropy alloys and other relatively hard binary alloys.”

All seven authors are from Lehigh University, including Rickman; Helen M. Chan, New Jersey Zinc Professor of materials science and engineering; Martin P. Harmer, Alcoa Foundation Professor of materials science and engineering; Joshua Smeltzer, graduate student in materials science and engineering; Christopher Marvel, postdoctoral research associate in materials science and engineering; Ankit Roy, graduate student in mechanical engineering and mechanics; and Ganesh Balasubramanian, assistant professor of mechanical engineering and mechanics.

Rise of High-Entropy Alloys and Data Analysis

The field of high-entropy, or multi-principal element, alloys has recently seen exponential growth. These systems represent a paradigm shift in alloy development, as some exhibit new structures and superior mechanical properties, as well as enhanced oxidation resistance and magnetic properties, relative to conventional alloys. However, identifying promising HEAs has presented a daunting challenge, given the vast palette of possible elements and combinations that could exist.

Researchers have sought a way to identify the element combinations and compositions that lead to high-strength, high-hardness alloys and other desirable qualities, which are a relatively small subset of the large number of potential HSAs that could be created.

In recent years, materials informatics, the application of data science to problems in materials science and engineering, has emerged as a powerful tool for materials discovery and design. The relatively new field is already having a significant impact on the interpretation of data for a variety of materials systems, including those used in thermoelectrics, ferroelectrics, battery anodes and cathodes, hydrogen storage materials, and polymer dielectrics.

“Creation of large data sets in materials science, in particular, is transforming the way research is done in the field by providing opportunities to identify complex relationships and to extract information that will enable new discoveries and catalyze materials design,” Rickman said. The tools of data science, including multivariate statistics, machine learning, dimensional reduction and data visualization, have already led to the identification of structure-property-processing relationships, screening of promising alloys and correlation of microstructure with processing parameters.

Lehigh University's research contributes to the field of materials informatics by demonstrating that this suite of tools is extremely useful for identifying promising materials from among myriad possibilities. “These tools can be used in a variety of contexts to narrow large experimental parameter spaces to accelerate the search for new materials,” Rickman said.

New Method Combines Complementary Tools

Lehigh University researchers combined two complementary tools to employ a supervised learning strategy for the efficient screening of high-entropy alloys and to identify promising HEAs: (1) a canonical-correlation analysis and (2) a genetic algorithm with a canonical-correlation analysis-inspired fitness function.

They implemented this procedure using a database for which mechanical property information exists and highlighting new alloys with high hardnesses. The methodology was validated by comparing predicted hardnesses with alloys fabricated in a laboratory using arc-melting, identifying alloys with very high measured hardnesses.

“The methods employed here involved a novel combination of existing methods adapted to the high-entropy alloy problem,” Rickman said. “In addition, these methods may be generalized to discover, for example, alloys having other desirable properties. We believe that our approach, which relies on data science and experimental characterization, has the potential to change the way researchers discover such systems going forward.”

###

The research was funded by the Office of Naval Research with support from Lehigh University's Nano/Human Interface Initiative.