Drexel Researchers Develop New Method for Invisible Dirt-Repelling Brushes

Drexel materials scientist Christopher Li, PhD, reports a new way for making polymer nanobrushes that equates to growing a lawn by rolling out sod instead of planting seeds.

Credit: Drexel University

You might not be aware of it, but invisible carpets of polymers are keeping things from being sticky right now. The lenses of your glasses might be coated with them to stave off smudges. They're keeping the underbellies of ships from corroding, artificial joints from locking up and medical devices from gathering germs. The name “polymer nanobrush” doesn't seem fitting because these bristly materials aren't used to sweep away debris, they actually prevent it from accumulating at all.

The science behind their production sounds a lot like turf management on a golf course. But for years it's been done one blade — or bristle — at a time, or by sprinkling some seeds and hoping for the best. Materials scientists from Drexel University have planted a new idea — that they can make better brushes by rolling them out like sod.

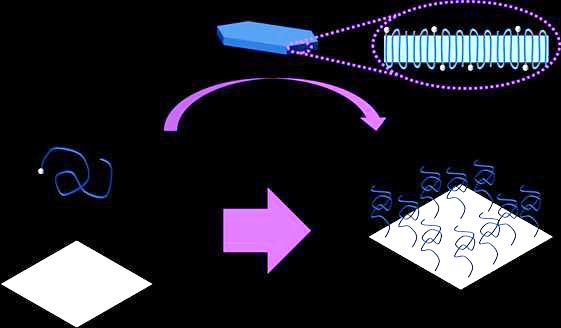

Until recently, polymer brushes have been made in two main ways. One, called “grafting-from,” is like sprinkling seeds on soil and waiting for grass to take root. The other, “grafting-to” is more like transplanting individual blades of grass. In a recent edition of Nature Communications, Christopher Li, PhD, a professor in Drexel's College of Engineering, explains his new method for brush making that's gives scientists a higher degree of control over the shape of the brush and bristles, and is much more efficient.

Li's approach involves growing a functional two-dimensional sheet of polymer crystals — similar to a nanoscale piece of double-sided tape. When the sheet is stuck to an existing substrate, and the crystals are dissolved, the remaining polymer chains spring up, forming the bristles of the brush.

“The past few decades witnessed exciting progresses in studies on polymer brushes, and they show great promises in various fields, including coating, biomedical, sensing, catalysis to name just a few,” said Li, whose research in the Drexel Soft Materials Lab focuses on materials that have complex structural and dynamic properties — like polymer brushes. “We believe that our discovery of a new way to make polymer brushes is a significant advance in the field and will enable use of the brushes in exciting new ways.”

Polymer brush materials are especially useful in situations where pieces need to fit tightly together but need to be able to move without friction throwing a wrench in the works. They are also effective for keeping important surfaces free of particles, chemicals, proteins and other fouling agents. Polymer brushes have been used to coat everything from eyeglass lenses, boats and medical devices — where they keep away smudges, damaging chemicals and germs — to artificial joints and mechanical components in vehicles — where they act as a lubricant.

The relative amount of friction that can be reduced by the brushes has to do with how long and rigid the polymers are and how far apart they're spaced. Li's method is significant because he can precisely tune all of these characteristics because he can control the formation of the two-dimensional crystal sheets. In the paper he reports the creation of the most densely packed polymer brushes to date, with bristles less than a nanometer apart.

“These surface-functionalized 2D single crystals provide a unique opportunity for the synthesis of well-defined polymer brushes,” Li said. “The key step in our method is pre-assembling polymers into polymer single crystals before coupling them onto the substrate.”

For Li's group — which has pioneered research in growing spherical crystals, and solid polymer electrolytes for energy storage — controlling the formation of crystalized polymers for an application like this is almost second nature.

According to the paper, the team is even able to create polymer crystals with anchor points on both ends so they form a loop, which is a much sturdier bristle formation than a single-anchored polymer.

“What this all means is that one day engineers will be able to tailor-make incredibly durable polymer brush coatings to extend the usage lives of all kinds of uniquely shaped joints and couplings,” Li said. “This shifts the way we look at making the brushes and I think it will have a lasting impact on this area of research.”