Characterizing and designing lubricants on the computer

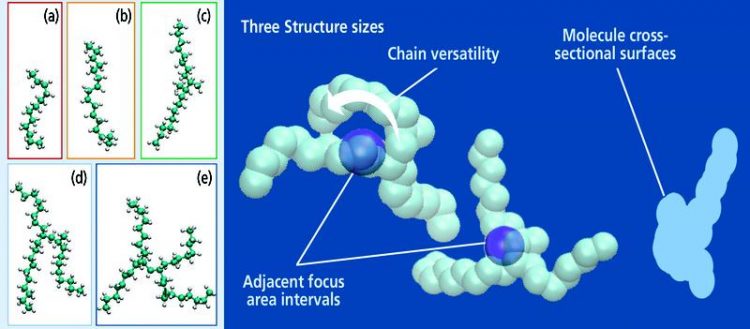

Alkane molecules whose viscosity have been calculated via molecular dynamics simulation at high pressure and high temperature conditions (left) as well as the required molecular structure properties. © Fraunhofer IWM

In order to develop a new lubricant or to improve upon an existing one, it is important to precisely understand its behavior: pressure, temperature, shear rate and viscosity are important parameters.

'It’s very difficult to measure the lubricant film experimentally because the conditions required to do so can rarely be set in a controlled manner', explains Dr. Kerstin Falk, member of the Multiscale Modeling and Tribosimulation group at the Fraunhofer Institute for Mechanics of Materials IWM in Freiburg.

'In some areas, for example, such extreme loads occur that pressure in the Giga-Pascal range is generated locally', says the expert in tribology, the science of friction, lubrication and wear. Simulations can help where experiments are difficult: up to now, predictions for lubricant behavior at high pressure have mostly been obtained by extrapolating the results of experiments in a normal pressure range. Unfortunately, this approach fails at the extremely high pressures that occur locally in lubricated frictional contacts.

Precise calculations of viscosity at high pressure

Using atomistic molecular dynamics simulations, the physicist can predict lubricant properties such as viscosity under controlled, arbitrarily adjustable pressure and temperature conditions. 'We have been very successful in calculating the viscosity for various model lubricants at pressures of up to 700 Mega-Pascals', says Dr. Kerstin Falk.

'Our model lubricants consisted of simple linear or branched alkanes', she continues. Alkanes or paraffins are very stable chains of carbon and hydrogen which are the basic components of many common lubricants and fuels.

Lubricants characterized by their molecular properties

But Falk's real goal was to obtain a more practical prediction model than had been previously possible. It should allow for viscosity value calculations for certain conditions in the tribo gap without having to carry out complex molecular dynamics simulations.

For this purpose, Dr. Kerstin Falk and her colleagues Dr. Daniele Savio and Prof. Michael Moseler used atomistic simulations which, almost like a 'virtual super magnifier', provide insights into the microscopic structure and dynamics of the lubricant molecules. In this way, the team found out which three molecular properties of a lubricant significantly determine its viscosity: the molecular cross-sectional areas, the chain flexibility and the distance between the individual molecules. With these properties identified, the viscosity of a lubricant can easily and accurately be calculated under a wide variety of conditions.

'Additionally, using this simulation method, we can also find the right molecules for certain tribological stresses', says Dr. Falk. 'And in combination with additional quantum chemical simulations of the lubricant interaction with component surfaces, we can suggest a suitable lubricant for a given application to our clients', adds Prof. Michael Moseler.

In the future, these new results will also serve as a basis for investigating lubricant behavior at very high speeds and thus high shear rates. Also examined will be the ways in which lubricants behave in very narrow friction gaps which are only a few molecule diameters wide. Dr. Kerstin Falk and her colleagues can also characterize other lubricants with the new method – for example, water-based lubricants for environmentally compatible applications.

Publication:

Falk, K.; Savio, D.; Moseler, M.; Nonempirical free volume viscosity model for alkane lubricants under severe pressures, Physical Review Letters 124/10 (2020) 105501, DOI: https://doi.org/10.1103/PhysRevLett.124.105501

Dr. Kerstin Falk, Telephone +49 761 5142-242, kerstin.falk@iwm.fraunhofer.de

Falk, K.; Savio, D.; Moseler, M.; Nonempirical free volume viscosity model for alkane lubricants under severe pressures, Physical Review Letters 124/10 (2020) 105501, DOI: https://doi.org/10.1103/PhysRevLett.124.105501

Falk, K.; Savio, D.; Moseler, M.; Nonempirical free volume viscosity model for alkane lubricants under severe pressures, Physical Review Letters 124/10 (2020) 105501, DOI: https://doi.org/10.1103/PhysRevLett.124.105501 Press Release as PDF

https://www.iwm.fraunhofer.de/en/services/tribology/multiscale-modeling-tribosim… Multiscale Modeling and Tribosimulation at the Fraunhofer IWM

Media Contact

All latest news from the category: Materials Sciences

Materials management deals with the research, development, manufacturing and processing of raw and industrial materials. Key aspects here are biological and medical issues, which play an increasingly important role in this field.

innovations-report offers in-depth articles related to the development and application of materials and the structure and properties of new materials.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…