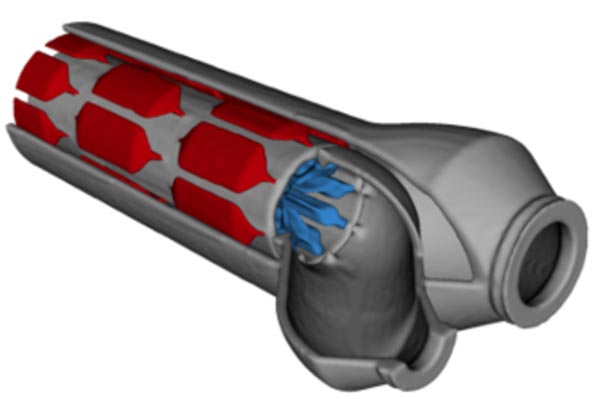

Demonstrating next-generation energy technology, researchers at the University of Illinois Urbana-Champaign are using topology optimization and metal 3D printing to design ultra-compact, high-power heat exchangers. Used in most major industries – including energy, water, manufacturing, transportation, construction, electronic, chemical, petrochemical, agriculture and aerospace – heat exchangers transfer thermal energy from one medium to another. For decades, heat exchanger designs have remained relatively unchanged. Recent advancements in 3D printing allow the production of three-dimensional exchanger designs previously thought impossible. These new…

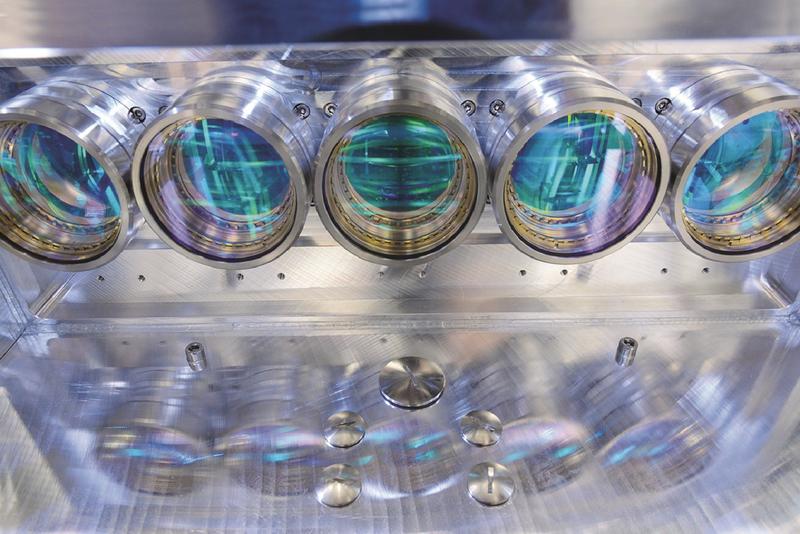

… for Assembling Optical Systems with Maximum Precision. The Fraunhofer Institute for Laser Technology ILT in Aachen has been developing and building laser systems for use in space for several years. At the same time, the Aachen scientists are also researching technologies for metallic 3D printing. Using the Laser Powder Bed Fusion (LPBF) process, Fraunhofer ILT – along with the Chair for Digital Additive Production DAP – has developed and set up a new precision gripper arm made of metal…

The research team of the Faculty of Mechanical Engineering at Landshut University of Applied Sciences and Spiess Motorenbau GmbH is developing a new method to measure heat flows in combustion engines more quickly than before; a technique which is also relevant to the research into alternative fuels and fuels that contain hydrogen When we start a car engine, combustion gases with very high temperatures of more than 1,000 degrees Celsius are produced. When these hit the cylinder and piston walls,…

Fraunhofer IWS evaluates thousand times faster beam shaping. Laser experts from Saxony and Israel are jointly testing a novel laser for industrial use at the Fraunhofer Institute for Material and Beam Technology IWS in Dresden. The system is based on the “Coherent Beam Combining” (CBC) method, which is still new for high-power lasers. The 13-kilowatt laser can generate different energy distribution patterns particularly quickly during operation and thus process even demanding high-tech materials very precisely and quickly. The Fraunhofer researchers…

ASTM Awards Contract to Fraunhofer ILT. The Fraunhofer Institute for Laser Technology ILT has received an award for decades of development in the field of additive manufacturing: The Aachen-based institute won a competition conducted by ASTM International and is now working on a project towards standardization of machine condition monitoring in laser beam powder bed fusion (LB-PBF). It is focusing on selecting and qualifying imaging sensor technology that can be used to specifically monitor the condition of LB-PBF systems. Finally,…

Automated production of CFRP composite parts… Fast, lightweight and fuel efficient: RACER, the high-speed helicopter reaches flying speeds of up to 400 kilometers per hour. The components of its outer shell are made by an innovative, highly automated manufacturing process. A research team at the Fraunhofer Institute for Casting, Composite and Processing Technology IGCV developed the innovative, sustainable method together with Airbus Helicopters. At over 400 kilometers per hour, RACER — short for Rapid and Cost-Effective Rotorcraft — moves through…

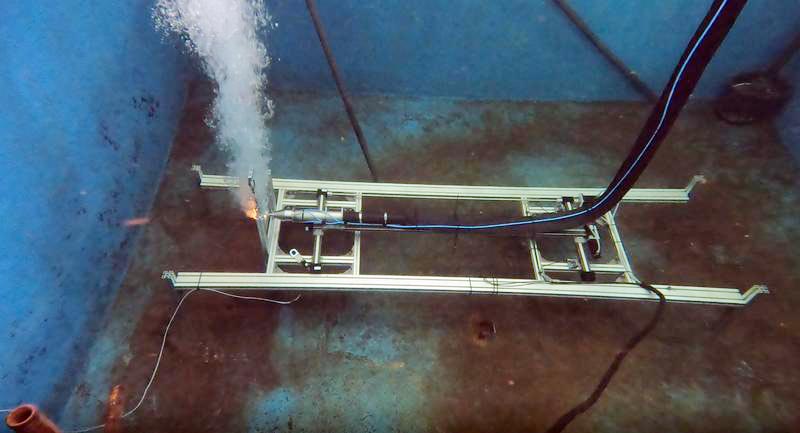

More and more nuclear power plants are reaching their maximum service life or are decommissioned due to the nuclear phase-out. To reduce the additional effort of water filtration during dismantling, scientists at the Laser Zentrum Hannover e.V. (LZH) have developed and validated a laser-based cutting process. With this method, up to 95 percent less radioactively contaminated secondary waste is released into the water when the reactor vessel internals are cut. In direct dismantling, the reactor components are disassembled on-site within…

Neutrons “see” internal stress in component from additive manufacturing. 3D printing has opened up a completely new range of possibilities. One example is the production of novel turbine buckets. However, the 3D printing process often induces internal stress in the components which can in the worst case lead to cracks. Now a research team has succeeded in using neutrons from the Technical University of Munich (TUM) research neutron source reactor for non-destructive detection of this internal stress – a key…

Helicopters are to become faster, greener and quieter. An international team led by Airbus Helicopters (AH) is working on the technology to achieve these goals with the RACER demonstrator. Scientists from the Technical University of Munich (TUM) have designed an aerodynamically shape-optimized rotor head full fairing for the innovative RACER rotorcraft. The fairing will reduce energy consumption and make higher speeds possible. Vertical take-off and landing aircraft are essential whenever there’s not enough room for runways, for example in mountain…

In order to help the industry have greater access to raw materials, the Fraunhofer Institute for Laser Technology ILT and Cronimet Ferroleg. GmbH have jointly developed a laser-based sorting process for metal scrap as part of the BMBF-funded “PLUS” project. A new sensor they have developed makes the recycling of metallic raw materials many times more efficient than previously possible. The EU project “REVaMP” goes one step further: In this project, Fraunhofer ILT experts have also been contributing their expertise…

Test bench proves successful in regular operation The Fraunhofer Institute for Wind Energy Systems IWES has completed a successful series of accelerated tests on rotor blade bearings at the bearing test bench in Hamburg. Within the scope of research and industry projects, bearings were subjected to dynamic endurance tests to increase their reliability and gain insights into the causes of wear. The first bearing tests were thoroughly successful with both the test method developed by Fraunhofer IWES and the test…

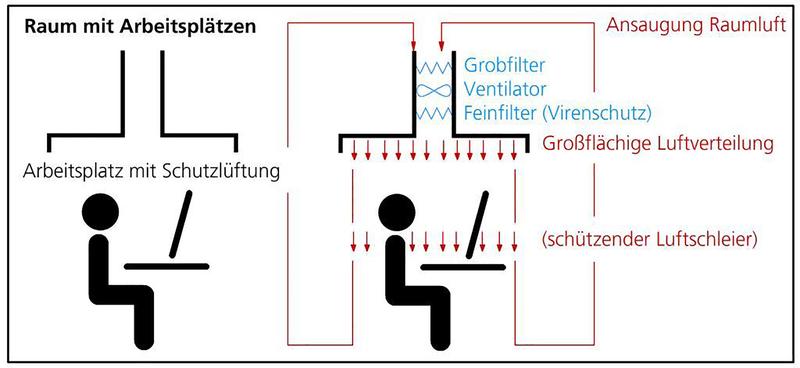

People who are required to serve a large number of customers at a checkout or counter are at a particularly high risk of exposure to COVID-19. At the Fraunhofer Institute for Building Physics IBP, a type of air lock was therefore developed to shield work stations from the surrounding air using constant ventilation. This “protective canopy” will be unveiled to the public from January 13 to 15, 2021, at the online BAU trade fair. The coronavirus pandemic has fundamentally changed…

Automation solutions from the joint project “Impulse“ funded by the German Federal Ministry for Economic Affairs and Energy (BMWi) – sub-project “Tempo“ Automation is one of the most important strategies for increasing efficiency in production. The positioning and drilling end effector newly developed for a portal system to automate the pre-assembly of stiffening elements (cleats) on CFRP integral frames for the manufacture of aircraft fuselages – made available by project partner Airbus Hamburg – enables production rate increases both with…

The greatest potential of digitalization in companies in which materials play a prominent role lies in the cross-process linking of materials data. This promises to shorten component development times, faster optimization of complex manufacturing processes and more reliable plant operation. The problem is the very heterogeneous nature of materials data, which makes linking within this data extremely complex. The research project MaterialDigital of the state of Baden-Württemberg under the leadership of the Fraunhofer Institute for Mechanics of Materials IWM in…

The dynamic change in root growth of plants plays an important role in their adjustment to soil conditions. Depending on the location, nutrients or moisture can be found in higher or lower soil layers. This is why, depending on the situation, a short or a long root is advantageous. Caroline Gutjahr, Professor of Plant Genetics at the Technical University of Munich (TUM), and her team investigate how plant hormones influence the growth of roots. Roots are essential for reaching water…

How optimally joined aluminum and fiber composite plastics contribute to climate protection In order to improve city air quality and protect the environment, many municipalities are planning to acquire electric refuse vehicles for their parks and pedestrian passages. However, these are equipped with heavy batteries or fuel cells and can therefore usually transport less waste than classic waste trucks with combustion engines. However, German engineers now intend to change this by using lightweight designs. To this end, the Fraunhofer Institute…