Strong innovations: “Reference-factory.H2”, intelligent machine components in adaptive process chains, human-robot interaction and soft robotics demonstrate solutions for industrial green hydrogen, the factory of the future, household, and nursing. Reference-factory.H2: advancing the industrial production of electrolyzers and fuel cells Anyone who considers acquiring a photovoltaic system for their domestic roof may con-sider a significantly lower budget than ten or fifteen years ago, in spite of current price fluctuations. Highly efficient industrial large series production realizes the lower prices. An individual…

Forming presses are widely used as key elements of industrial production processes. From automotive technology to refrigerators, almost every product we encounter contains formed parts. The purchasing costs of these machines can reach double-digit millions, and it takes a great deal of time to set up and adjust precisely as needed. Given such a high level of investment, buyers expect machinery of this kind to keep running efficiently for a long time without any loss in quality. At the Hannover…

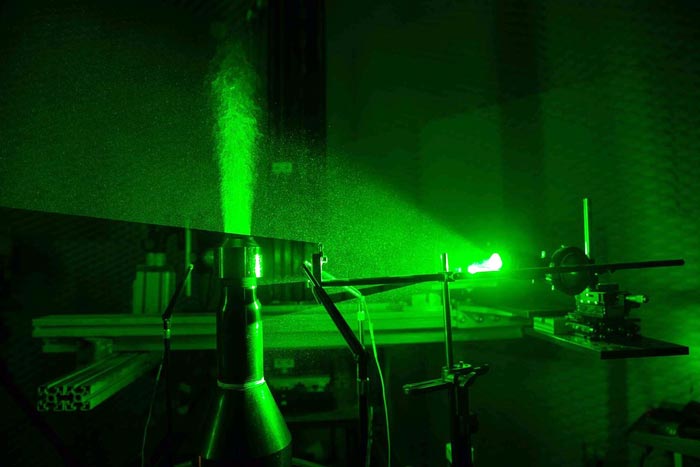

Brass is used for many components, but welding the copper alloy is challenging. The Laser Zentrum Hannover e.V. (LZH) wants to change this together with LMB Automation GmbH, Iserlohn. In the project LaserMessing, they are developing a laser-based manufacturing system for automated production of brass components such as fittings, bearings, valves, turbines or heat exchangers. Within the project LaserMessing, the scientists of the LZH are working on a welding process that combines laser-based deep welding and cored wire processes. The…

Fraunhofer IWS develops efficient, fast and sustainable coatings for industrial components. High-power diode lasers with outputs of ten or more kilowatts open new application scenarios for laser cladding. Particularly sustainable and resource-efficient coatings can be produced and applied, for example in automotive, machine construction and other industries. Together with industrial partners, the Fraunhofer Institute for Material and Beam Technology IWS has developed applications and specific processes for this laser class to industry readiness under the label “HICLAD®”. The Dresden institute…

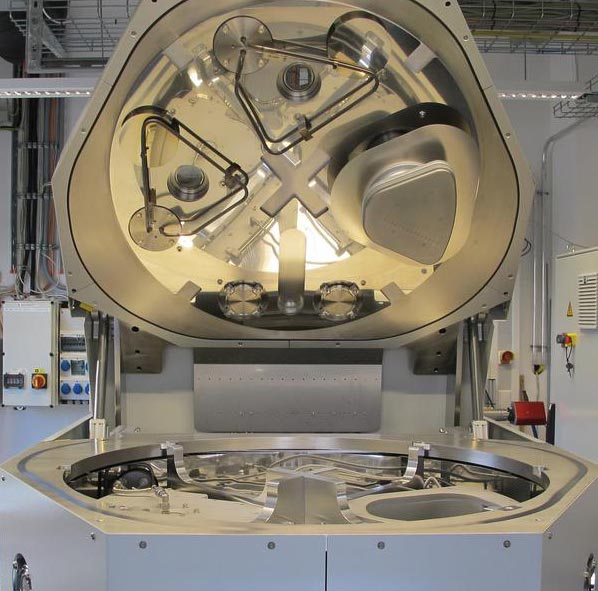

… at the LZH can precisely coat complex-shaped optics. With a new Spatial ALD system, the Laser Zentrum Hannover e.V. (LZH) can now also uniformly coat complex-shaped optics. The innovative system achieves higher deposition rates than previously possible – and is of interest, among others, for applications in the automotive lighting or VR/AR sectors. ALD (atomic layer deposition) technology can produce very thin, high-quality coatings. So far, the ALD process has been used primarily to produce thin functional layers in…

Currently, flatbed screen printing is the standard process used for the metallization of silicon solar cells and many other electronic components. Using a new production machine developed jointly with ASYS Automatisierungssysteme GmbH, researchers at the Fraunhofer Institute for Solar Energy Systems ISE have now managed to increase the print throughput by a factor of 1.5. In order to achieve this, rotation screen printing and flexographic printing were used for the first time. With the new machine, the research team achieved…

Fraunhofer IPA has developed a new, flexible transportation robot that specifically addresses the needs of healthcare facilities such as hospitals and nursery homes. Transport and logistics tasks are part of everyday working life in healthcare facilities. However, they take up valuable staff time that is not available for care activities. Even though driverless transportation vehicles are already being used in many large hospitals, they can only operate in separate supply wings. In addition, some service robots have been introduced, which…

Methanol reformers convert easy-to-transport methanol into hydrogen. But conventional reformers still come with a number of drawbacks – catalyst attrition, to name but one example. An innovative methanol reformer for mobile applications from the Fraunhofer Institute for Microengineering and Microsystems IMM is able to overcome these challenges. Hydrogen is the beacon of hope for the energy transition, as it is set to sustainably shape both mobility and industrial processes. But at present, there is still limited availability, as transporting hydrogen…

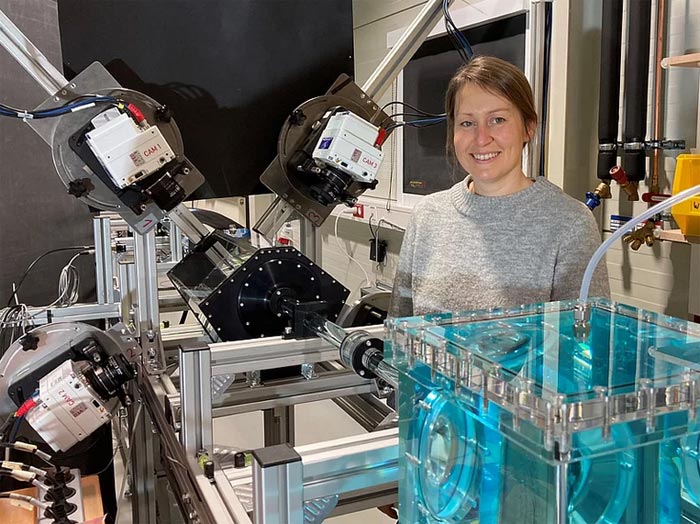

New Research Findings… Coffee sloshing over the rim of a cup: annoying, but bearable. Sloshing fuel in rockets or tankers: more dangerous. Dr. Kerstin Avila from the University of Bremen conducts research on this topic and on turbulence – with success, as two outstanding publications now show. Sloshing coffee is known to many people as an annoying everyday problem that one can and must live with. In engineering, however, such dynamics can have fatal effects. “Sloshing fuel endangers the flight…

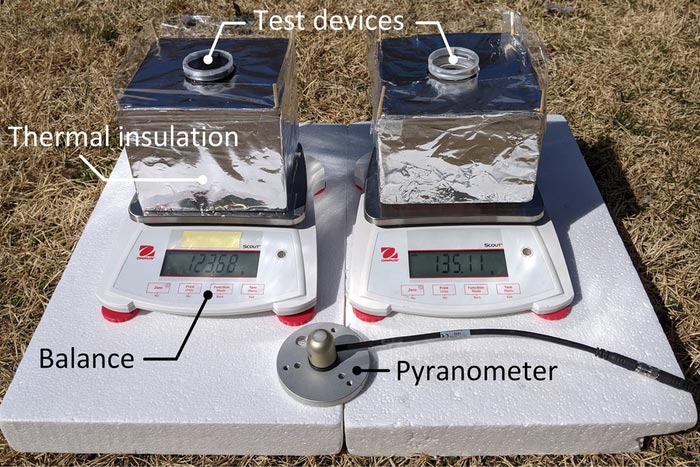

Passive solar evaporation system could be used to clean wastewater, provide potable water, or sterilize medical tools in off-grid areas. An estimated two-thirds of humanity is affected by shortages of water, and many such areas in the developing world also face a lack of dependable electricity. Widespread research efforts have thus focused on ways to desalinate seawater or brackish water using just solar heat. Many such efforts have run into problems with fouling of equipment caused by salt buildup, however,…

From 2023, rail vehicle manufacturers will be able to have their braking systems tested and certified on the TU Graz campus. In addition, the new test rig will allow for the first time investigations of brake loads and their effects on the complete chassis. “With this test rig, we are opening up a new area of research and entering uncharted territory,” says a delighted Martin Leitner. The term “uncharted territory” was deliberately chosen by the head of the Institute of…

Geothermal systems are becoming an increasingly important source of clean and, above all, baseload-capable energy. But the wells, which can be several thousand meters deep, are risky, and things can sometimes go wrong. Fraunhofer scientists have now developed an innovative tool that enables additional branches to be drilled off of the main well. This decreases the risk of dry boreholes and improves the output. Geothermal energy is an inexhaustible energy source. Hot water from reservoirs, fissures and cracks can be…

World first: Fraunhofer IWS for the very first time prints quadrupole components for linear accelerators. A new generation of particle accelerators aims at taking cancer therapy, drug detection and material analysis to a higher level: These linear accelerators are so compact that they are becoming affordable even for smaller hospitals, airports and laboratories. To support this development, the Fraunhofer Institute for Material and Beam Technology IWS, together with the European Organization for Nuclear Research (CERN) in Switzerland, Latvia’s Riga Technology…

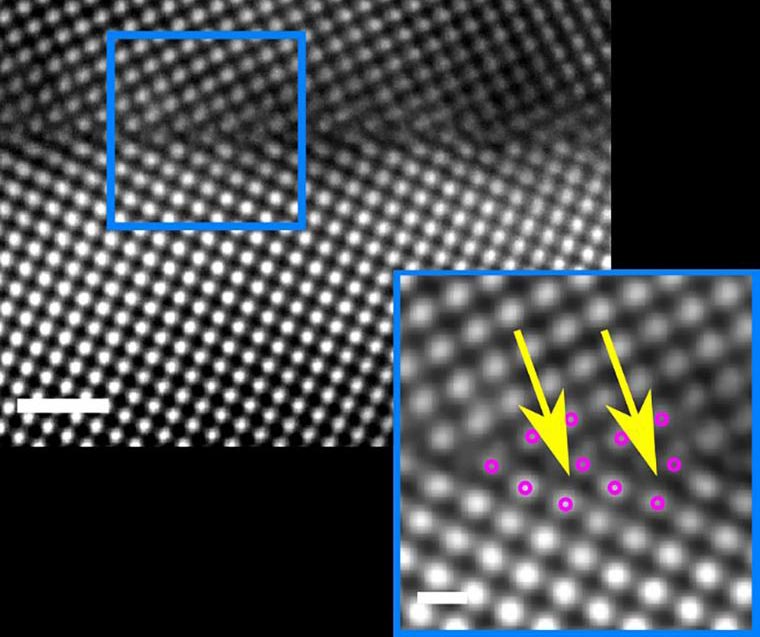

Iron (Fe) is known and utilized by mankind since thousands of years, but until now, we know very little about the local chemistry at the interfaces separating different crystallites, so-called grain boundaries. Beyond that, how different solute species interact remains elusive. What happens when two or more elements diffuse to the grain boundary and segregate there? How do they interact with each other and how will they influence the interfacial properties? Ali Ahmadian, researcher in the department Structure and Nano-/Micromechanics…

Filter solutions for high technology processes. Metal processing with lasers and plasma releases many different pollutants into the ambient air. The Fraunhofer Institute for Material and Beam Technology IWS, together with partners, has developed a filter system that efficiently removes these substances from the air. The filter can be adapted to the various materials and substances released in each case. In the future, the technology will be used in other applications, such as additive manufacturing. Microparticles and harmful gases as…

Lab tests show promise for reducing jet noise in commercial and military aviation. Aerospace engineers at the University of Cincinnati have come up with a new nozzle design for F-18 fighter planes to dampen the deafening roar of the engines without hindering performance. Distinguished professor Ephraim Gutmark, an Ohio Eminent Scholar, and his students in UC’s College of Engineering and Applied Science designed and tested the new nozzles on 1/28th-scale jet engines in his aeroacoustics lab. The interior of the…