Researchers have created an Artificial Intelligence (AI) system that allows a quadrupedal robot to adjust its gait to various unknown terrains, akin to a genuine animal, marking what is considered a world first. The innovative technology enables the robot to automatically modify its movement, rather than requiring instructions on when and how to adjust its stride, as is the case with current-generation robots. This advancement is regarded as a significant progression towards the potential deployment of legged robots in perilous…

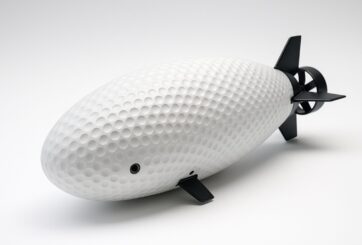

A spherical prototype that can change its surface from smooth to dimpled cuts through drag and generates lift Captions // Photos on Flickr // Video on Youtube Underwater or aerial vehicles with dimples like golf balls could be more efficient and maneuverable, a new prototype developed at the University of Michigan has demonstrated. Golf ball dimples cut through pressure drag—the resistance force an object meets when moving through a fluid—propelling the ball 30% further than a smooth ball on average….

In industrial stamping processes, several hundred sheet metal parts are typically produced per minute. Together with the stamped parts manufacturer Quittenbaum GmbH, researchers at Fraunhofer IPM have now for the first time developed and installed an optical inspection system that checks the dimensional accuracy of every single component in high-speed stamping processes – with an accuracy in the range of 100 micrometers. The geometric deviations are depicted in 16 different views on the user interface. © Fraunhofer IPM Connectors, sleeves…

A team of researchers has beaten its own record for the fastest swimming soft robot, drawing inspiration from manta rays to improve their ability to control the robot’s movement in the water. “Two years ago, we demonstrated an aquatic soft robot that was able to reach average speeds of 3.74 body lengths per second,” says Jie Yin, corresponding author of a paper on the work and an associate professor of mechanical and aerospace engineering at North Carolina State University. “We…

Detonation is a supersonic combustion wave, characterized by a shock wave driven by the energy release from closely coupled chemical reactions. It is a typical form of pressure gain combustion, converting chemical energy into thrust efficiently. The concept of harnessing detonation to improve thermodynamic cycle efficiency and enhance the performance of aerospace propulsion systems has been a subject of interest for many years. Since the 1950s, various types of detonation engines have been proposed, including pulse detonation engines, oblique detonation…

A thing of the past! Bipolar plates for fuel cells are mass produced every second. The forming tools used to manufacture them are milled from high-quality metal alloys that provide them with high wear resistance. In the National Action Plan for Fuel Cell Production (H2GO), the Fraunhofer Institute for Laser Technology ILT in Aachen is breaking new ground: Instead of milling the tools from an expensive solid block, the institute is using extreme high-speed laser material deposition (EHLA) to apply…

MIT engineers look to manta rays… New research shows the filter-feeders strike a natural balance between permeability and selectivity that could inform design of water treatment systems. Filter feeders are everywhere in the animal world, from tiny crustaceans and certain types of coral and krill, to various molluscs, barnacles, and even massive basking sharks and baleen whales. Now, MIT engineers have found that one filter feeder has evolved to sift food in ways that could improve the design of industrial…

… mitigates three defects simultaneously for failure-free metal parts. University of Wisconsin–Madison engineers have found a way to simultaneously mitigate three types of defects in parts produced using a prominent additive manufacturing technique called laser powder bed fusion. Led by Lianyi Chen, an associate professor of mechanical engineering at UW–Madison, the team discovered the mechanisms and identified the processing conditions that can lead to this significant reduction in defects. The researchers detailed their findings in a paper published on November…

Have you ever wondered why an airplane has a vertical tailfin? The plane needs it to stabilize its flight. Since flying without a vertical tail is much more energy-efficient, the aviation industry has worked hard to accomplish this – so far without much success. However, birds don’t need a vertical fin, which raises the question: how do they do it? David Lentink, Professor of Biomimetics at the University of Groningen, has developed a robotic bird model with real pigeon feathers…

‘MiniMax’ aerosol separator impresses with outstanding performance and efficiency. In view of increasing legal and industrial requirements, the development of efficient exhaust gas purification technologies is very important. The need for innovative solutions for the separation of very fine particles is increasing, particularly in technical processes. A research team from the Institute of Mechanical Process Engineering at the University of Stuttgart has now developed a new filter technology: the ‘MiniMax’ aerosol separator. The Technology Licence Bureau (TLB) is supporting the…

Achieving Individual Functional Integration. Wire or Fiber Encapsulating Additive Manufacturing (WEAM/FEAM) could significantly simplify the industrial production of components that require the integration of complex yet compact wiring, sensors, actuators, or lighting systems – by directly printing these components into the parts. A new development at Fraunhofer IWU: the Automated Cable Assembly (AuCA). Conventional robotics fails to produce and automatically lay flexible cable bundles in vehicles; AuCA, however, manufactures the wiring using a robot-guided way on a component and fixes…

“Doing instead of procrastinating”. This is the AI strategy presented by Prof. Constantin Haefner, Director of the Fraunhofer Institute for Laser Technology ILT, at the “AKL’24 – International Laser Technology Congress” in Aachen, Germany. Experts at the institute are putting this pragmatic strategy into practice in the German-Canadian AI-SLAM project, for example, in which an AI tool for the automated laser cladding of wear parts for the mining industry is being developed. AI-SLAM: Five letters stand for the ambitious German-Canadian…

Taking inspiration from bird feathers, Princeton engineers have found that adding rows of flaps to a remote-controlled aircraft’s wings improves flight performance and helps prevent stalling, a condition that can jeopardize a plane’s ability to stay aloft. “These flaps can both help the plane avoid stall and make it easier to regain control when stall does occur,” said Aimy Wissa, assistant professor of mechanical and aerospace engineering and principal investigator of the study, published in the Proceedings of the National…

Initial tests at new battery recycling plant at TU Freiberg sucessful. A research team at TU Bergakademie Freiberg is using a new shredder system to investigate how battery cells can be shredded in such a way that as many of the raw materials they contain can be efficiently recovered. In the new plant, the researchers are also capturing highly volatile substances that were previously lost. Sensors and cameras record the processes and send the data to a database for analysis…

Robotic, Modular and Agile System to Enable Production of Customized Battery Cells in Required Quantities. According to Germany’s Federal Ministry for Economic Affairs and Climate Action, battery cells are gaining in importance as a versatile and efficient means of storing energy. They are a driving force in advancing electromobility, for example, and a key technology of great strategic and economic significance for manufacturing companies. Current demand is mainly met through cost-driven mass production in Asia and North America, which also…

Additive Manufacturing, particularly metal 3D printing, has evolved from a promising technology to a serious constituent of industrial production. Dr. Stefan Leuders, head of Technology & Innovation at voestalpine Additive Manufacturing Center GmbH, Düsseldorf, and Dr. Tim Lantzsch, head of Laser Powder Bed Fusion at the Fraunhofer Institute for Laser Technology ILT, Aachen, discuss the current trends in Additive Manufacturing (AM), analyze the opportunities and risks, and show which industries can particularly benefit. We are delighted to talk to two…