Sustainable Tool Manufacturing: Innovations in Process Chains

Whether drilling, turning or milling: In machining – as well as in primary forming and re-forming, die casting and many other applications – tools are of pivotal importance for industrial production.

Their performance significantly influences both the quality and the cost of the manufactured product and, consequently, the economic and ecological sustainability of the production process. One objective of the work at the Fraunhofer Institute for Surface Engineering and Thin Films IST in Braunschweig is the development of resilient and smart tools under the requirements of sustainability.

The researchers thereby take the entire process chain into account – from tool design and material characterization, through pre-treatment, cleaning, and customized surface treatments and coatings, and on to testing and application.

The key to the manufacture of resilient high-tech tools which retain their value-adding and economic operability under even the highest stresses is an optimized tool construction. This encompasses both the selection of the material and the design, thereby taking into account geometry and topography as well as the use of heat treatments and suitable coatings. At the Fraunhofer IST, optimizations in the manufacturing process are therefore investigated throughout the entire process chain. The process begins with an analysis or characterization of the materials to be machined and an optimum design of the tool, which also includes the selection of a suitable coating.

The actual production process for the tools begins with the manufacture of the basic body. Following pre-treatment, e.g. etching, sandblasting and cleaning, the focus is directed on the optimal design of the surface. Depending on the tool and its intended use, this can, for example, be hardening by means of plasma diffusion treatment or a customized coating. In addition to access to a wide range of technologies and industrial equipment, the experts at the Fraunhofer IST can draw on many years of experience and user knowledge, enabling, for example, friction and wear properties to be specifically adjusted and tool life to be optimized. In order to exploit all efficiency potentials in terms of both energy and resource consumption, they combine the tribological functional coatings with thin-film sensor technology where necessary. Very thin sensor layers, directly in the main stress zones of the tools, enable the recording of relevant process data such as pressure, temperature or wear. These so-called smart tools therefore fulfil the prerequisites for the digitalization of processes and process chains and, furthermore, offer a diverse range of approaches for the optimization of production in terms of quality, safety, productivity and flexibility.

The concluding step in the process chain is the testing and quality assurance of the tools. For the sustainability assessment of the various measures, development-related life-cycle analyses (LCA, LCC) are performed at the institute.

The use of resilient and smart tools in conjunction with a digital process chain offers major potential for safe, efficient, flexible and sustainable production and can therefore provide a contribution towards increasing Germany’s competitiveness and securing its position as a production location.

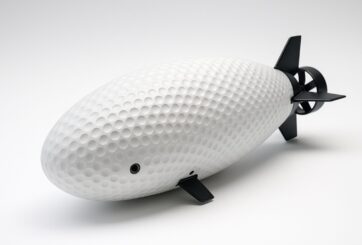

On the Fraunhofer joint stand in the “Production” section (Hall 16, Stand A12) at the Hannover Messe, the Fraunhofer IST will be demonstrating the potential of coating and surface technology for the manufacture of sustainable tools. Exhibits will include cobalt-free carbides for machining, service-life-optimized tools with CVD diamond coating, and smart and resilient tools for die casting and re-forming.

Weitere Informationen:

https://www.ist.fraunhofer.de/en/press-media/2023/nachhaltige-prozessketten.html…