SUPERSMART – paper-based printed electronics …

… as environmentally friendly and cost-efficient alternative.

The SUPERSMART research project funded by EIT RawMaterials has shown proof: printed electronic components such as sensors and smart labels on paper can play an essential role in building a smart environment for production, retail and logistics. Efficient and reliable production processes make them economically competitive. In terms of resource conservation, climate and the environment, electronics printed on paper have outstanding advantages over conventional substrates and manufacturing processes for smart electronic components. Yesterday the SUPERSMART project was awarded a prize in the 2021 OE-A competition (OE-A: Organic and Printed Electronics Association).

Why paper?

Arjowiggins France / © SUPERSMART project

The packaging market in Europe, as well as the electronics industry, is on the move. Miniaturized and cost-efficient electronic labels are able to monitor transport and logistics or provide forgery-resistant information about the origin and authenticity of products. Intelligent packaging creates added value; however, at the same time, plastic packaging in particular is facing a radical change. Society’s obligation to protect the climate and conserve resources has led to stricter guidelines and laws on the components that are still permitted (REACH, RoHS etc.). This also led to the EU Packaging Regulation to control the use of plastic packaging. Therefore, the search for more environmentally friendly and cost-efficient alternatives is becoming increasingly important for the economy.

Here, paper – a material used since ages – experiences a new utilization. Made from renewable raw materials, it is durable and the recycling is well established, and in the end, even biodegradable if processed appropriately. Up to now, paper has hardly played a role as carrier material for electronic devices, because paper cannot be combined with classic electronic manufacturing. In SUPERSMART, a European consortium with eleven partners has spent three years on bringing printed electronics to paper using highly scalable technological processes that also allow mass production.

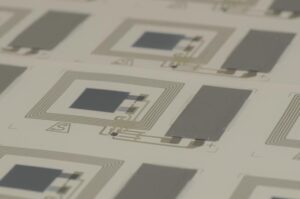

In SUPERSMART, materials and processes were matched for two application examples – a shock detection sensor and an intelligent anti-counterfeit label – to print electronic circuits and displays directly on paper. Both components can simply be read out via a cell phone app.

Availability of functional materials

One big challenge on the way to smart labels on paper was the availability of printable, functional, and affordable materials with reliable and constantly high quality without batch-to-batch variations. The SUPERSMART project put particularly attention on the scale-up and quality control of materials in order to support all companies that want to proceed with functional tags and smart labels. Next to functional paper, SUPERSMART put its focus and development for example on piezopolymers, ferroelectric nanoparticles, electrochromic materials, metal-oxide semiconductors and barrier coatings for papers.

In order to demonstrate that the up-scaled materials have the same quality for high-through-put techniques – compared to labels and materials processed in the lab – roll-to-roll and sheet-to-sheet processes were established. Even the poling of piezoelectric material was scaled up by an automated poling station. Pick-and-place technologies were applied on functional paper in order to integrate conventional microelectronic components (batteries, communication chips) if necessary.

Outstanding benefits for climate and environment

A life cycle assessment (LCA) was carried out to determine exactly how resource-efficient printed electronics on paper are and where potential for improvement is needed. Replacing organic or inorganic substrates with paper in manufacturing simplifies subsequent recycling and reduces waste both during processing and at the end of the product’s life. Printing processes consume less energy and resources than conventional semiconductor processes, the design for recycling is simplified as well. In a direct LCA comparison between paper and PET substrates for production of thin film electronic devices, paper shows a clear advantage over PET. In almost all of the 18 categories examined in the LCA (e.g., global warming, water use or eutrophication, stratospheric ozone depletion, or ecotoxicity) the use of a paper substrate would cause only 10-20 % of the environmental impact of PET.

Technological breakthrough for paper-based electronics

With its approach to apply well-engineered high-throughput processes for the printing of electronic components, the SUPERSMART project has removed major hurdles and pushed printed electronics to a higher level of technological maturity. Additionally, the paper-based sensors and labels are attractive for numerous applications. They can easily be integrated into packaging and consumer goods. An anti-counterfeit tag for particularly vulnerable or expensive goods can help to protect manufacturers and consumers from fraud. Large-area shock detection sensors integrated into packaging or other paper-based elements provides transportation protection and event traceability. Finally, these printed elements can be used as security features, that add reliable and cost-efficient smartness to simple products. The smarter the packaging, the greater is the benefit. Even completely new areas of application are conceivable, such as filter technology or in the education sector.

The SUPERSMART project team is proud to have been selected by the international jury as the winner of the 2021 OE-A competition within the category “Best Publicly Funded Project Demonstrator”. The award ceremony will take place on April 15, 2021.

Partners

Arkema, France (project coordination)

Arjowiggins France S.A.S, France

Centre National de la Recherche Scientifique-2 (CNRS-UB), France

Coatema Coating Machinery GmbH, Germany

French Alternative Energies and Atomic Energy Commission (CEA), France

Fraunhofer Institute for Silicate Research ISC, Germany

Fraunhofer Institute for Process Engineering and Packaging IVV, Germany

Joanneum Research, Austria

Luquet & Duranton, France

VTT Technical Research Centre of Finland Ltd. (VTT), Finland

NOVA School of Science and Technology | FCT NOVA, Universidade NOVA de Lisboa, Portugal

Université de Bordeaux, France

Wissenschaftliche Ansprechpartner:

Dr Fabrice Domingues Dos Santos, Arkema Piezotech (project co-ordinator)

Gerhard Domann, Fraunhofer ISC

Weitere Informationen:

Project website: https://SUPERSMART-project.eu/