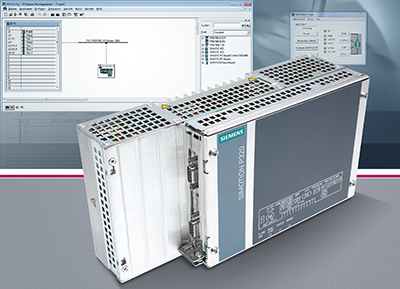

Siemens is presenting the Simotion P320-4, a compact, PC-based Motion Control System for tough operating conditions. The new Motion Control System is available in two versions with different processors: the Simotion P320-4 Embedded with an Intel Core i3 processor, and the Simotion P320-4 Standard with an Intel Core i7 processor.

The use of these Intel processors doubles the performance of the system in comparison to the previous generation, and the shorter memory access times also make a contribution. Siemens has designed the Simotion P320-4 without any mechanical wearing parts. It has a solid-state drive (SSD) or an optional CFast Card mass storage system in place of conventional hard disks.

The space-saving design has integrated safety functions but no rotating parts. The Motion Control System requires no maintenance, even when used at maximum processor performance and at an ambient temperature of up to 55 degrees Celsius. Typical application areas for the PC-based Motion Control System are production machines, filling plants, and wafer production in the solar industry.

Because of its compact design and narrow footprint, the Simotion P320-4 takes up little space in the control cabinet. The device can be installed on a standard mounting rail, or via vertical, side or wall mounting. The industrial PC not only has a Profinet fieldbus interface with three ports, but also the usual standard PC interfaces, such as USB 3.0, Ethernet, DVI-I and Displayport.

These enable easy connection of HMI displays. Siemens offers touch displays ranging in size from 12 to 22 inch, or 15 inch combined touch and key displays. The Simotion P320-4 is engineered with Simotion Scout software, which enables users to configure, parameterize and program their motion control applications quickly and easily. The engineering software also offers integrated test and diagnostics functions.

The latest storage technology with integrated error correction facilitates a high standard of data consistency. Siemens guarantees that the PC-based Motion Control System will remain available for the long term with the same hardware.

For further information on the Simotion P320-4, please see

www.siemens.com/simotion

Siemens AG (Berlin and Munich) is a global technology powerhouse that has stood for engineering excellence, innovation, quality, reliability and internationality for more than 165 years. The company is active in more than 200 countries, focusing on the areas of electrification, automation and digitalization. One of the world's largest producers of energy-efficient, resource-saving technologies, Siemens is No. 1 in offshore wind turbine construction, a leading supplier of combined cycle turbines for power generation, a major provider of power transmission solutions and a pioneer in infrastructure solutions as well as automation, drive and software solutions for industry. The company is also a leading provider of medical imaging equipment – such as computed tomography and magnetic resonance imaging systems – and a leader in laboratory diagnostics as well as clinical IT. In fiscal 2014, which ended on September 30, 2014, Siemens generated revenue from continuing operations of €71.9 billion and net income of €5.5 billion. At the end of September 2014, the company had around 343,000 employees worldwide on a continuing basis.

Further information is available on the Internet at www.siemens.com

Reference Number: PR2015040170DFEN

Contact

Mr. Peter Jefimiec

Digital Factory Division

Siemens AG

Gleiwitzer Str. 555

90475 Nuremberg

Germany

Tel: +49 (911) 895-7975

peter.jefimiec@siemens.com