Steel piston production: Forging undercuts with novel forging tool

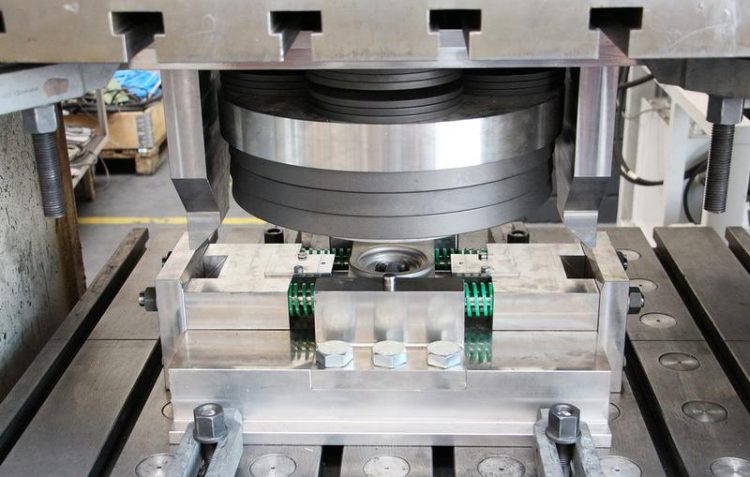

The forging tool creates undercuts: A model will be presented at Hannover Messe. Photo: IPH

Conventional forging tools are not suited to create undercuts, since afterwards part removal from the tool is impossible. Undercuts are areas or protrusions which are perpendicular to the forming direction. One example is the pin bore in steel pistons for combustion engines: Up to now, it has to be drilled after forging.

With the new forging tool developed at IPH, bores can be pre-formed already during the forging process. The tool disposes of two horizontally driven sliders.

When the die moves down, the sliders are driven horizontally into the hot steel billet, thus forming the area for the pin bore – the undercut. When the die moves up again, the sliders are driven back, and the forged part can be removed from the tool.

Forging undercuts facilitates subsequent machining considerably, speeding up the manufacturing process and reducing the overall costs. Moreover, about five percent less material and thus less energy during the forming process is needed, when pre-forming pin bores during the forging process. In future, steel pistons can thus be produced much faster and at a lower price, causing less impact on the environment.

In addition, the novel forging approach may also increase part quality. The reason: The cutting process interrupts the grain flow, while bulk metal forming makes use of it, thus reducing unfavourable notch effects. To the researchers’ opinion, this will make the piston more reliable.

The scientists of the Institut für Integrierte Produktion Hannover gGmbH (IPH) have developed the novel tool in cooperation with industrial partners. The approach is based on multidirectional forming, a technology which has been investigated at IPH for nearly twenty years.

For the production of crankshafts, it has already been refined and scaled up to manufacturing standards. Within the scope of the project “Forging Undercuts”, the researchers’ focus was primarily on high-strength steel pistons, as used in small, fuel-efficient turbo engines. However, the principle can easily be transferred to other components.

On the occasion of Hannover Messe taking place from 24 to 28 April 2017, the researchers will showcase their development to the general public for the first time. A model of the tool will be presented at the Lower Saxony Pavilion in Hall 2, Stand A08. Interested companies and journalists may contact Susann Reichert of IPH via email reichert@iph-hannover.de for free tickets.

http://www.hinterschnittschmieden.de Further information on the research project

Media Contact

More Information:

http://www.iph-hannover.deAll latest news from the category: Trade Fair News

Newest articles

Properties of new materials for microchips

… can now be measured well. Reseachers of Delft University of Technology demonstrated measuring performance properties of ultrathin silicon membranes. Making ever smaller and more powerful chips requires new ultrathin…

Floating solar’s potential

… to support sustainable development by addressing climate, water, and energy goals holistically. A new study published this week in Nature Energy raises the potential for floating solar photovoltaics (FPV)…

Skyrmions move at record speeds

… a step towards the computing of the future. An international research team led by scientists from the CNRS1 has discovered that the magnetic nanobubbles2 known as skyrmions can be…