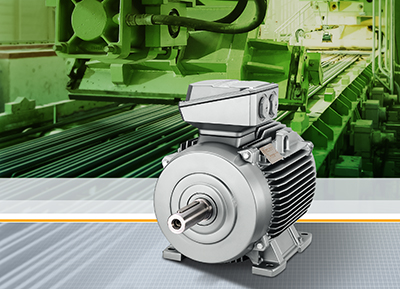

Specially designed for applications in the steel industry: the new Simotics DP Steel Plant Motors from Siemens.

Siemens has developed industry-specific motors for steel plants on the basis of the Simotics 1LE1 motor platform. The ventilated Simotics DP Steel Plant Motors expand the range of roller table motors, and are specially designed for applications in the steel industry where they meet the high demands in terms of vibrations and shocks according to Class 3M4.

Versions of these new motors are optimized for use with converters of the Sinamics S120 series and, as integrated drive systems, contribute to reliable and efficient operation. In network operation, the IE3 efficiency class ensures particularly high energy savings.

The new Simotics DP Steel Plant Motors from Siemens offer optimized solutions for steel production processes. In particular, these include the transport processes, for example transport to the reheating furnace and cooling bed, on beam rolling mills or run-out tables.

The motors feature a mechanical design that has been continuously tested in accordance with to DIN EN60721-3-3 and exhibit a correspondingly high resistance to vibration and shocks, compliant with Class 3M4. They are available in 4- and 6-pole designs with shaft heights from 112 to 280 mm and in the torque range from 20 to 578 Nm.

The Steel Plant range comprises not only mains powered motors, but also versions optimized for converter operation with special insulation systems. When used together with the Sinamics S120 drive system, these motors form an integrated drive system that contributes to particularly dynamic and reliable production processes. Furthermore, operation with the Sinamics S120 converter enables group drives to be implemented with a high level of synchronization.

For further information please see www.siemens.com/simotics

Siemens AG (Berlin and Munich) is a global technology powerhouse that has stood for engineering excellence, innovation, quality, reliability and internationality for more than 165 years. The company is active in more than 200 countries, focusing on the areas of electrification, automation and digitalization. One of the world's largest producers of energy-efficient, resource-saving technologies, Siemens is No. 1 in offshore wind turbine construction, a leading supplier of combined cycle turbines for power generation, a major provider of power transmission solutions and a pioneer in infrastructure solutions as well as automation, drive and software solutions for industry. The company is also a leading provider of medical imaging equipment – such as computed tomography and magnetic resonance imaging systems – and a leader in laboratory diagnostics as well as clinical IT. In fiscal 2014, which ended on September 30, 2014, Siemens generated revenue from continuing operations of €71.9 billion and net income of €5.5 billion. At the end of September 2014, the company had around 357,000 employees worldwide.

Further information is available on the Internet at www.siemens.com

Reference Number: PR2014110061PDEN

Contact

Mr. Stefan Rauscher

Process Industries and Drives Division

Siemens AG

Gleiwitzer Str. 555

90026 Nuremberg

Germany

Tel: +49 (911) 895 7952

stefan.rauscher@siemens.com