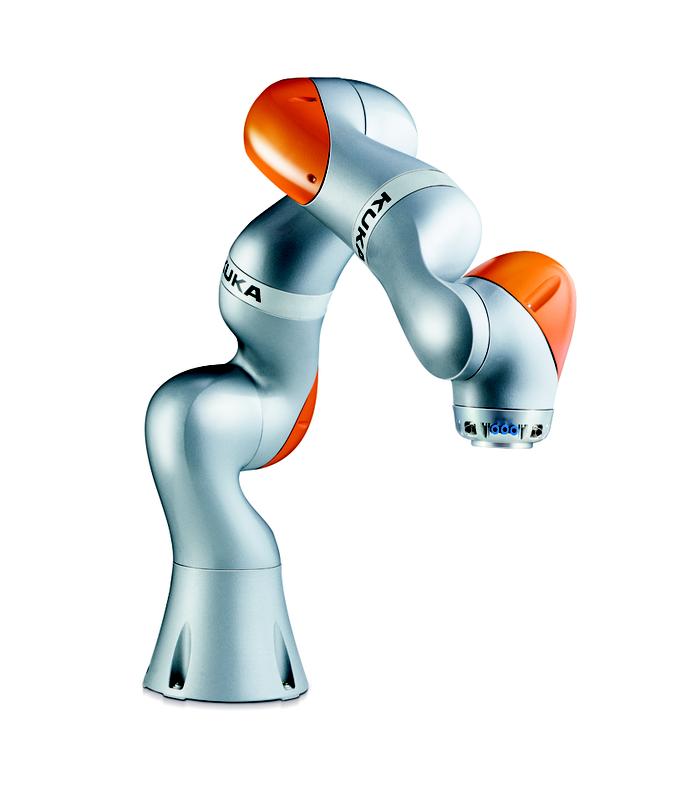

The lightweight construction robot “intelligent industrial work assistant” guarantees that man and machine cooperate smoothly.

© KUKA AG, Augsburg, Germany.

Fraunhofer ILT from Aachen relies on a clever combination of robotics and a laser scanner with new optics as well as process monitoring, which it has developed itself. In focus is a new light-weight robot (LBR is German for lightweight robot) developed by Kuka Roboter GmbH from Augsburg. According to company statements, not only is the LBR iiwa, or “intelligent industrial work assistant (iiwa)”, the first sensitive robot to be manufactured in series, but it also helps man and robot work closely together.

Spacer provides optical distance

The Aachen researchers have mounted a relay-optic and a spacer on the collaborating robot (Cobot), the latter of which ensures that the optics complies with the distance (focal length) required for the process. The LBR iiwa “feels” when the spacer touches the weld and starts the welding process. Thus, the welding points are always held at a constant distance from the lens thanks to the spacer and the sensing robot.

In Munich, Fraunhofer ILT will be using concrete applications to demonstrate how the microjoining process in battery technology can be made more precise and reliable with the help of this lightweight robot. In detail, it is addressing how to better weld prismatic, round and pouch cells.

In a demonstration, the institute combines the two processes of microjoining and 3D printing, in which this welding process plays a leading technical role. The Aachen-based scientists will be presenting a technology demonstrator on how a copper contact element can be connected to a round cell via LaserTAB.

The Fraunhofer ILT has also developed a specially shaped copper connector, which it manufactures on its own with Selective Laser Melting (SLM), also known as Laser Beam Melting or Laser Powder-Bed Fusion (L-PBF).

No more complicated positioning necessary

All possible applications point to the advantages of the new robot-assisted process, in which the user guides the robot directly to the point of use. It saves the previous, elaborate search of the focus position and the cumbersome positioning of the laser. In addition, the spacer ensures that the focus position does not change during joining and that the connector is pressed against the workpiece or the battery.

Elaborate clamping devices are, therefore, superfluous or can be less complex. In particular, users will appreciate how the system mechanically maintains the distance of the optics to the welding site, especially when they have to balance production tolerances or different heights. In these challenging situations with their mostly very complex geometries, the robot-assisted LaserTAB works much more precisely than conventional methods.

Fraunhofer ILT at the productronica

More information on LaserTAB will be available at the joint Fraunhofer stand B2.317 at productronica, the world's leading trade fair for electronics development and production, from November 14 to 17, 2017 in Munich.

Contact

Johanna Helm M. Sc.

Micro Joining Group

Telephone +49 241 8906-8382

johanna.helm@ilt.fraunhofer.de

Dr.-Ing. Alexander Olowinsky

Group Manager Micro Joining

Telefon +49 241 8906-491

alexander.olowinsky@ilt.fraunhofer.de

http://www.ilt.fraunhofer.de/en