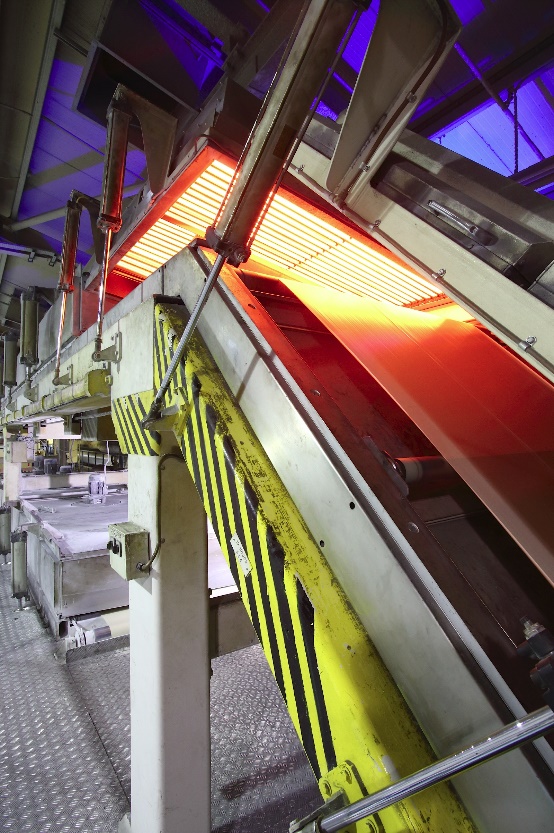

Heraeus Noblelight develops special drying and curing solutions tailored to the production process to optimise the use of energy, reduce costs and save time. (Picture: Heraeus Noblelight GmbH)

Easy retrofitting at a paper coating line

By simply retrofitting a Heraeus Noblelight infrared system,Smith & Mclaurin in Great Britain were able to speed up and improve their production of labels.

Smith & Mclaurin Ltd is a leading manufacturer and global supplier of self-adhesive labels, tags and tickets. Based at Johnstone, Renfrewshire, the company is selling reels of materials to printing houses and processors that manufacture finished labels and tags for a wide range of end users such as supermarkets, pharmacies, logistics companies and food-processing companies.

An important part of the production process is the application of silicone materials to the label strips. Provided with an adhesive, the silicone is attached to the rear of the label strips and then dried and cured. Previously, this was done using a 20 years-old combined system of infrared and hot-air oven. However, increased demand required a higher speed of the production line and the existing infrared oven was unable to manage this.

Smith & Mclaurin had already successfully been operating a carbon infrared system (CIR) at another line and so the engineers contacted Heraeus and retrofitted a 192 kW CIR oven directly downstream of the existing hot-air oven. The CIR system comprises two modules with 96 kW each, which were installed above the line, each module being equipped with 15 medium-wave carbon emitters arranged in 10 individually controllable zones. This allows the output to be increased from 0 kW to 192 kW in ten equal steps to meet the specific requirements of the production process.

“The success of this second infrared installation further increases our confidence in the technology,” comments Iain McCourty, Engineering manager at the Renfrewshire site. “The ability of the Carbon medium wave system to provide heat instantaneously and uniformly through the applied coatings has ensured that we can now increase line speed. At the same time, the controllability of the system means that we are obtaining a much more reliable, and hence better quality, adhesive cure.”

Efficiently cross-linked with optimal use of energy

In order that coatings, paints or inks remain nice to look at, durable and scratch-proof, they need to be dried and cured sufficiently and optimally. This requires that wavelengths as well as UV light intensity and dose be adjusted to the photoinitiators of the varnish formulation or the coating.

Heraeus Noblelight offers different UV solutions for the pretreatment or curing of paints, inks and coatings.

The range includes innovative LED technology, special surface lamps (UVC Cure) or conventional UV medium-pressure lamp systems as well as microwave-powered UV lamp systems. Based on curing process, material, coating and ink or lacquer formulation, the UV solutions are tailored to the individual process requirements.

The different UV systems emit intensive UV light in the wavelength range of 200 to 400 nanometres. The wavelengths of the lamps are optimised for the photoinitiators of the lacquer system or coating to achieve efficient and sufficient cross-linking. This enables higher production speeds and improved process reliability. The processing of the surface can continue without much delay or the surface is scratch-resistant or durable at the end of a curing process.

From start to finish: Heraeus UV light sources accompany the entire production process

Prior to application of the coating or printing, the surface tension can be reduced and the surface energy increased by means of VUV radiation (vacuum UV). Due to the resulting changed wetting properties, materials can be processed further better and faster. After that, the UV coating or printing is cured.

Intensive microwave-powered UV medium-pressure systems with appropriate doping or UV LED systems are used for this. Selection of a suitable UV solution also allows intermediate curing steps. Finally, the surface can be further improved by means of a special UVC cure system. Similar to UV LEDs, the system emits monochromatic UV radiation in the UVC range. This makes surfaces significantly more scratch-resistant.

Heraeus UV solutions can be used depending on which process step is to be optimised. The use of advanced UV LED technology is a promising option to lower the energy consumption and heat generation. UV LEDs are ozone-free and long-lasting. This makes maintenance easy and saves money. The current developments of UV LED coatings and lacquers enable curing with UV LEDs despite the monochromatic spectrum. Conventional UV technologies such as UV medium-pressure lamp systems dry and cure paints across a wide, polychromatic spectrum with a very high intensity. This allows high speeds and reliable curing processes. The cured paints or inks give the surfaces a brilliant appearance.

All UV and IR systems can be used separately or in combination to tailor the drying and curing solution to your requirements. Application experts give advice as to how drying and curing processes can be optimised and energy can be saved by the purposeful use of UV and IR radiation – for premium, scratch-resistant and durable surfaces.

Heraeus, the technology group headquartered in Hanau, Germany, is a leading international family-owned company formed in 1851. We create high-value solutions for our customers, strengthening their competitiveness for the long term. Our activities focus on a number of markets: chemical and metals, energy and the environment, communications and electronics, health, mobility, and industrial applications. In fiscal year 2013, Heraeus achieved product revenue of €3.6 billion and precious metals trading revenue of €13.5 billion. With some 12,500 employees in over 110 subsidiaries worldwide, Heraeus holds a leading position in its global markets.

Heraeus Noblelight GmbH with its headquarters in Hanau and with subsidiaries in the USA, Great Britain, France, China and Australia, is one of the technology- and market-leaders in the production of specialist light sources and systems. In 2013, Heraeus Noblelight had an annual turnover of 138 Million € and employed 875 people worldwide. The organization develops, manufactures and markets infrared and ultraviolet emitters, systems and solutions for applications in industrial manufacture, environmental protection, medicine and cosmetics, research, development and analytical measurement techniques..

For more information, please contact:

Technical: Heraeus Noblelight GmbH

Reinhard-Heraeus-Ring 7

D-63801 Kleinostheim

Tel +49 6181/35-8545, Fax +49 6181/35-16 8545

E-Mail hng-infrared@heraeus.com

Press: Dr. Marie-Luise Bopp

Heraeus Noblelight GmbH,

Abteilung Marketing/Werbung

Tel +49 6181/35-8547, Fax +49 6181/35-16 8547

E-Mail marie-luise.bopp@heraeus.com

www.heraeus-noblelight.com