Creatively Additive: The LZH at the Hannover Messe 2018

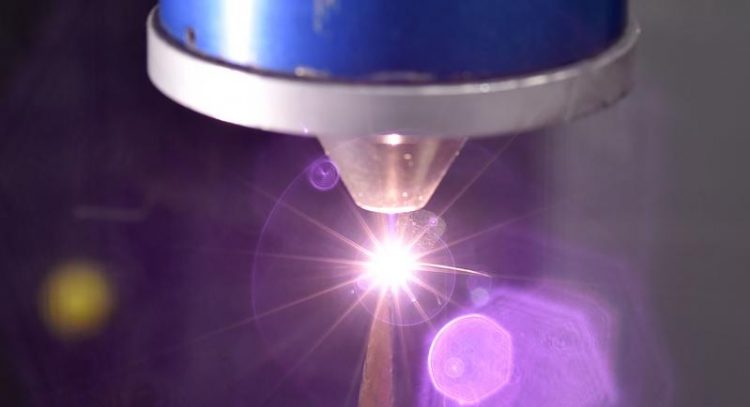

At the Hannover Messe 2018, the LZH will present special ways of additive manufacturing, here the single-crystalline repair of high-quality capital goods. Photo: LZH

The LZH develops and optimizes special processes for established materials as well as special materials. The scientists of the LZH conduct research on both polymers and metals.

Groundbreaking: multi-materials

Rarely do products consist of only one material. In order to be able to manufacture these additively in one go, the LZH is conducting research on multi-material printing. With nozzle-based methods, for example, the scientists can create hardness gradients in a polymer component. This is interesting, among other things, for wearables, in-ear hearing aids and headphones.

They should be soft and comfortable on the outside but hard enough on the inside to optimally ensure their function. Researchers continue to work on embedding metals in polymer matrices. Another option would be to print conductors or to magnetize components in that way. For this topic, the institute is looking for interested companies for joint research projects.

Lightweight, individual, robust: additive manufacturing of metal

The additive manufacturing of metals enables completely new ways of constructing components: Components for the automotive industry and the aerospace industry become lighter; special materials such as magnesium are used in lightweight construction as well as in biomedical engineering, functions can be integrated directly in one manufacturing step, implants are adapted exactly to the body.

Selective Laser (micro)Melting, which is being researched by the LZH scientists, makes all these applications possible. Additive manufacturing is just as suitable for repairing or protecting valuable components. With laser-assisted deposition welding, the LZH can apply large quantities of material to provide large components, such as shafts, with a protective layer. At present, 7.5 kilograms per hour can be reliably deposited. Valuable goods such as turbine blades can be repaired by single-crystalline laser deposition welding.

The LZH is not only pursuing creative approaches in additive manufacturing – on the exhibition stand, in addition to additive manufacturing, the institute will highlight the safe deactivation of World War II bombs, and other areas of laser material processing.

Media Contact

More Information:

http://www.lzh.de/All latest news from the category: Trade Fair News

Newest articles

High-energy-density aqueous battery based on halogen multi-electron transfer

Traditional non-aqueous lithium-ion batteries have a high energy density, but their safety is compromised due to the flammable organic electrolytes they utilize. Aqueous batteries use water as the solvent for…

First-ever combined heart pump and pig kidney transplant

…gives new hope to patient with terminal illness. Surgeons at NYU Langone Health performed the first-ever combined mechanical heart pump and gene-edited pig kidney transplant surgery in a 54-year-old woman…

Biophysics: Testing how well biomarkers work

LMU researchers have developed a method to determine how reliably target proteins can be labeled using super-resolution fluorescence microscopy. Modern microscopy techniques make it possible to examine the inner workings…