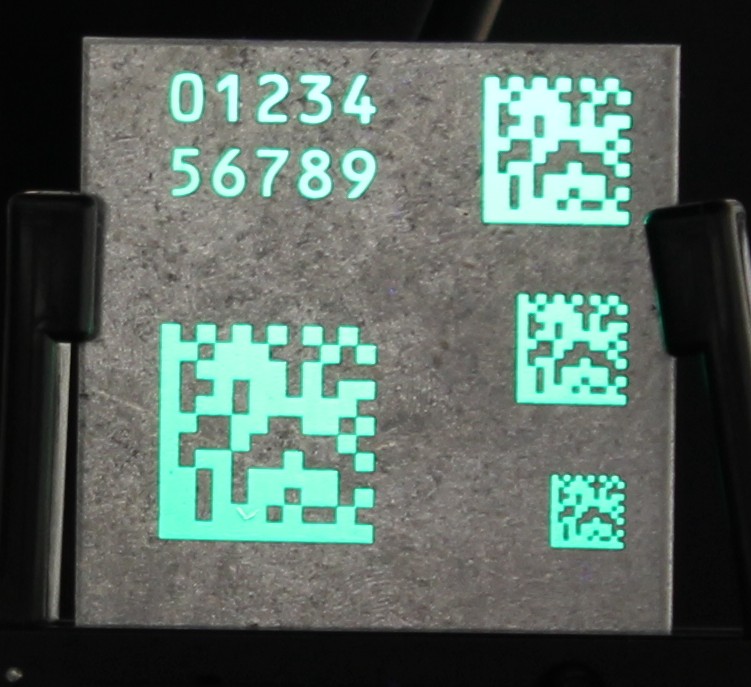

Sample under UV.

Individual marking of heat-treated metal components

For a reliable, clear and tamper-proof marking of semi-finished and end products there are a variety of labeling solutions on the market. These range from a simple serial number to integrated RFID chips (Radio Frequency IDentification).

However, these solutions do not meet the specific requirements of metal processing. Inks, for example, turn out to be problematical as they are thermally stable only up to 250 °C. Thus, their use is not possible at the elevated workpiece temperatures of up to 1250 °C.

In addition, during processing the material surface may change, which can reduce the contrast between the material and the marking so that automated readout fails. Stickon labels in turn apply too much material and thus interfere with further processing.

Markings that withstand high temperatures and chemical influences

Researchers at Fraunhofer IKTS took this challenge and developed a solution for the individual component marking. Core element of the process are ceramic phosphors that respond to optical excitation with a pronounced luminescence.

These phosphors are very robust: they withstand high temperatures, are resistant to harsh chemical environment, and can be added to a variety of materials. Thus, it is possible to incorporate the phosphors directly into inks or pastes, and to print on the metal surface.

“Depending on whether static or dynamic information is required, screen or inkjet printing is used. Both processes can be integrated into production lines. As only a minimal amount of material is printed, an influence on the workpiece characteristics or the adhesion of coatings is excluded”, explains Dr. Thomas Härtling, scientist at Fraunhofer IKTS.

Inks and pastes dosed with phosphors are safe and environmentally friendly, which means no additional health and safety measures are necessary. Due to the high contrast between marking and substrate, automated readout is possible in all lighting situations.

Protection against plagiarism by customized label properties

Both spectral properties and the luminescence decay time of the marking can be customized. Since this adjustment can take place both during and after the synthesis of phosphors, properties that can only be copied at costs arise. This advantage may, for example, be used in labeling of spare parts or other components.

From April 13 to 17, 2015, Fraunhofer IKTS researchers answer your questions in Hall 6 on Booth B16.

http://www.ikts.fraunhofer.de/content/dam/ikts/de/doc2/Messen/PI_Bright%20prospe..