Vision Flat – Workshop on coating on flat substrates

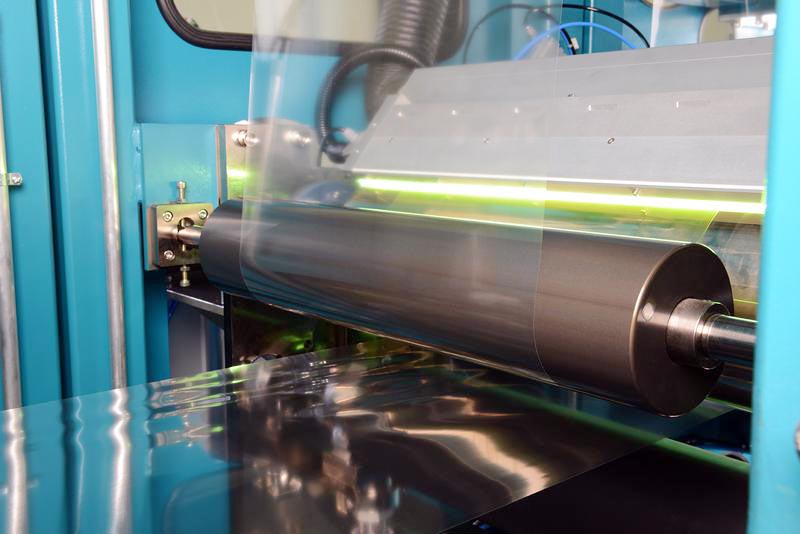

“Coating of Flat Substrates” has been one of the main business fields of Fraunhofer FEP for twenty years. During this period, an impressive technological platform was established. Today two vertical in-line sputter coaters offer a wide range of possibilities for research and development. The team is comprised of experts with many years of experience in process optimization and in creation of various layers or layer stacks.

Vision Flat is aimed to celebrate the achievements and, at the same time, to unite various approaches to glazing in order to address jointly the challenges in smart buildings of the future.

The two-day international and unique event comprises various aspects of energyefficient glazing.

The opening session focuses on the entire building envelopes on the holistic and architectural level. It also initiates the general discussion on the development of flat coating technology over the years and the requirements to the processes in view of current economic development.

Apart from that, novel concepts of flexible large area lighting and solutions on energy generation based on organic technology will be presented. Finally, the participants will be able to gain insights in one of the restauration projects conducted at the Green Vault (Grünes Gewölbe) in Dresden.

Whereas the opening session approaches the glazing in its entirety, the second day offers a possibility to participate in a detailed technological discussion, which includes the aspects of glass corrosion, glass processing by Flash Lamp Annealing, creation of precision coatings and the impact of glazing on energy efficiency in cars.

The closing session will deal with components applied in the coating process, as targets and sources, which enable to implement cost-efficient coatings on large areas.

Meet our experts and friends in a pleasant atmosphere and celebrate with us!

We are looking forward to inspiring discussions with partners and companies!

Press contact:

Annett Arnold

Organic Electronics, Electron Beam and Plasma Technology FEP| Phone +49 351 2586 452 | Annett.Arnold@fep.fraunhofer.de

Winterbergstraße 28 | 01277 Dresden | Germany | www.fep.fraunhofer.de

Weitere Informationen: