UKP-Workshop: Ultrafast Laser Technology 2015 – Productivity is the key

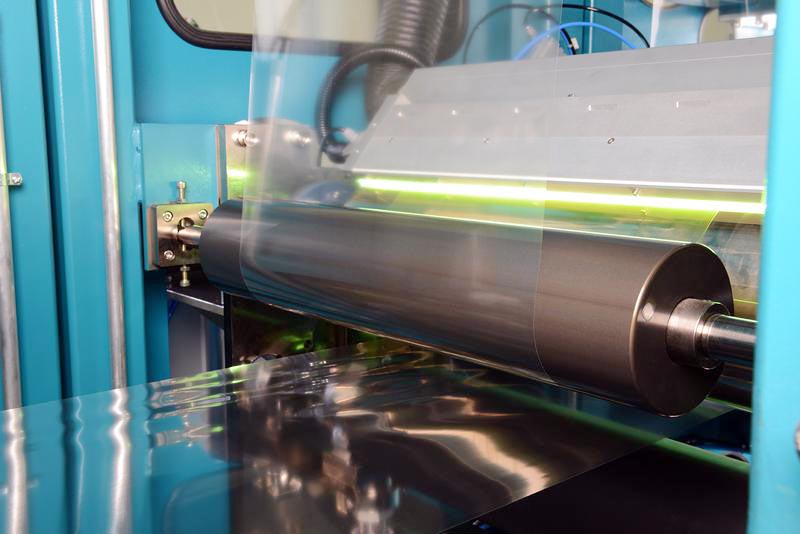

USP ablation on a roll-to-roll machine with beam splitting for the parallel processing of organic solar cells.

Picture source: Fraunhofer ILT, Aachen / Volker Lannert.

On April 22 and 23, over 160 experts from science and industry met up in Alsdorf near Aachen, Germany, for the 3rd UKP-Workshop: Ultrafast Laser Technology. Organized by the Fraunhofer Institute for Laser Technology ILT, this workshop explores the use of ultrafast lasers (USP) in industrial applications. Over the years, the focus has shifted from the development of reliable beam sources toward process engineering and new applications.

Strong and stable: Ultrafast lasers have come of age

Ultrafast lasers for industrial applications are currently available with low power ratings of 1 to 10 watts, but also with power ratings in excess of 100 W. According to the manufacturers, sales of these industrial systems have seen significant growth, particularly in Asia. Most users appeared thoroughly satisfied with the power of the available beam sources. People see the main challenge at present as translating this potential into practical applications, in other words efficiently using the available laser pulses with recourse to suitable process engineering.

At the same time, source development is progressing rapidly: systems that are both smaller and stronger will become possible over the coming years through miniaturization of lasers as well as an increase in the available power spectrum all the way up to kilowatt systems. Of course, these systems will be required to provide largely maintenance-free 24/7 operation over several years.

Rapid scanners and now also optical fiber cables for USP

The further development of process engineering is currently seen as the principal means of increasing productivity. New multi-beam techniques, which involve making as many beams as possible out of a single laser beam to process the workpiece simultaneously, seem a highly promising avenue.

This is made possible by diffractive optical elements. Also much discussed were dynamic solutions using SLMs (spatial light modulators) based on liquid crystals. However, these are currently limited to a frequency of 100 Hz, which points to a fundamental problem: whereas the laser sources offer repetition rates far into the MHz range, the scope for modulating individual pulses is still very limited.

At high pulse repetition rates, rapid movement of the spot is decisive in order to obtain high productivity and avoid thermal effects. To this end, scanner systems offering up to 1000 m/s are being developed, while industrial prototypes offering 300 m/s are already in use.

To the surprise of many workshop participants, USP optical fiber cables are also now ready for industrial use. This was long deemed inconceivable on account of the high beam intensity, but new developments based on photonic crystal fibers (PCF) now facilitate the flexible transmission of short laser pulses over several meters.

Process know-how: A rule of thumb for optimum ablation

Of course, correct process dimensioning is absolutely essential for high productivity. Several presentations described a simple rule of thumb in this respect: depending on the beam profile and material, there is an optimum fluence (energy per unit area) for ablation using ultrafast lasers.

At a lower fluence (less energy, same spot size), less material is ablated; at higher energy per pulse, the influence of thermal effects grows and ablation efficiency declines. In some of the examples presented, the optimum fluence value for the ablation of copper and steel was roughly three to six times the fluence at the ablation threshold. Once you have the optimum fluence value, you can easily calculate parameters such as pulse energy, repetition rate, spot size and overlap.

This knowledge is precious, because it takes into account thermal effects in cold ablation while also flagging up limits in the scaling of USP processes.

Safety is the watchword

Almost as an aside, one laser manufacturer mentioned that strong ultrafast lasers can also generate X-rays when processing metal. After all, it is not a new revelation by any means, since large projects such as Extreme Light Infrastructure (ELI) use precisely this effect to generate ultra-short X-ray pulses. On the other hand, the subsequent discussion showed that most users were unaware of this issue – as indeed they were of the generation of nanoparticles during ultrafast laser ablation.

Applications above all in semiconductor and display industries

Various standard USP applications have now established themselves. For example, one manufacturer used “hundreds of systems” for special marking tasks on a very well known tablet computer. Small 6 W systems mark the letters and big 100 W lasers draw the logo in anodized aluminum.

Ultrafast laser applications – particularly those involving ps systems – are currently very important in display manufacturing: glass cutting, sapphire ablation, the cutting of thin films and the structuring of sensors were all mentioned at the workshop. In the semiconductor industry, the scribing, drilling and dicing of chips predominate. For consumer electronics, the lasers are used for tasks such as trimming and drilling. In the automotive and aviation industries, the interest lies in specialized microstructuring, precision drilling and security marking jobs.

For all these applications, we can distinguish two principal kinds of application. Many tasks can be accomplished with systems of up to 10 W, including many (security) markings, scribing jobs and the processing of thin films. However, there is also a need for systems with higher power from around 100 W upward, chiefly at present for ablation tasks and multi-beam applications. Structuring surfaces with periodic patterns is a typical application in this area.

Outlook

Laser systems that use ultra-short pulses are developing and progressing in a highly dynamic fashion. Problems that were deemed insurmountable just a few years ago (such as flexible fibers for ultrafast lasers or rapid scanners) have already been resolved today or probably will be soon with new developments on the horizon. As for other issues such as process control, USP systems are now facing similar questions to other laser systems.

The integration of systems into new machines and processes is currently bringing significant progress on the road to digital photonic production. Overall, there is the expectation of exceptional growth both in beam sources and process engineering.

New developments in the application of USP lasers will be discussed at the 4th UKP-Workshop: Ultrafast Laser Technology on April 26 and 27, 2017, and also in a special session at the International Laser Technology Congress AKL’16 from April 27 to 29, 2016 in Aachen.

Contact

Dr. Arnold Gillner

Head of the Competence Area Ablation and Joining

Telephone +49 241 8906-148

arnold.gillner@ilt.fraunhofer.de

Fraunhofer Institute for Laser Technology ILT

Steinbachstraße 15

52074 Aachen, Germany