Coating free-form surfaces on large optical components

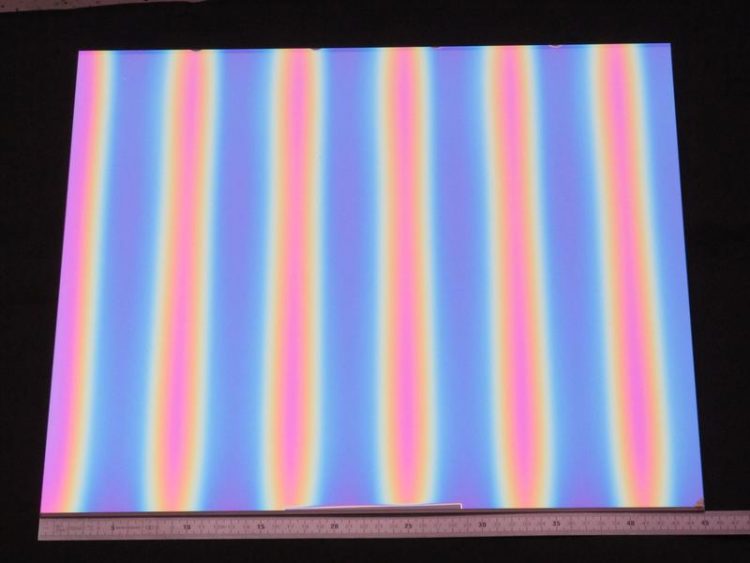

1-dimensional graded, nearly sinusoidal layer thickness curve on glass substrate (450x450 mm) © Fraunfofer FEP | Picture in printable resolution: www.fep.fraunhofer.de/press

Light plays an important role in more and more economic sectors and markets – including in data transmission, communication, energy generation, laser processing, and classical optics. Accordingly, the demands placed on high-performance optical products and systems are increasing rapidly. Components and integrated optical systems are becoming increasingly complex.

Only recently, a team of researchers from science and industry was awarded the “Forschung im Verbund” joint industry and science prize for the latest developments in free-form optical systems. Employment of increasingly complex surfaces in optics means the complexity of the coatings also increases.

Applications using complexly shaped surfaces that enable the viewer to see content or objects from different perspectives, or to achieve a desired optical effect with varying incident angles of light, require highly complex optical layer systems.

The scientists at Fraunhofer FEP have now succeeded in developing new processes and coating technologies that can be used for complex surfaces of large optical components. Specifically, this involves fabrication of lateral gradient layer systems.

The objective of this research is to manufacture optical layer systems adapted to applications characterised by variable angles of incidence, such as waveguides in holography, head-up displays, laser illumination, and laser processing systems. One focus has also been adapting the coating technology to larger surfaces, as a trend towards larger substrates with curved surfaces has become apparent.

The results make it feasible to better adapt to specific customer requirements by locally adjusting the optical function of optical multilayer systems. This applies in particular to coatings on large substrates or 3D substrates, where the incident angle of the light locally varies in the application. The optical function now can be adapted to the given incident angle of light.

Dr. Daniel Glöß, head of department Dynamic Coating explains: “The requirements for process control are very high. We basically have to adjust the coating thickness locally, which can be done either by accelerating the substrate movement during deposition or by varying the coating rate as a function of the substrate location. In both cases, we need very precise substrate movement.

With the PreSensLine, we have a coating system with the means for precision movement. The system control has now been adapted so that we can manufacture such coatings and offer them on a customer-specific basis.”

The complex requirements on the coating system were particularly challenging. As a result, through the joint research project “TopBePro” together with with AIS Automation Dresden GmbH, LSA GmbH and dresden elektronik ingenieurtechnik GmbH, Fraunhofer FEP scientists are now able to exert very precise temporal control over the different components (precision drive, coating sources, and power supply). Additional interfaces were implemented in EtherCAT and have achieved time resolution of the communication between components of <1ms.

Further development work is planned on the simulation in order to achieve the appropriate coating processes for the corresponding coating thickness profiles. In addition, the scientists are also looking to the future and intend to coat 3D substrates, such as larger mirrors and lenses, in addition to the existing planar coatings. The hardware requirements for this are met by the PreSensLine system at the Institute.

The scientists are open to discussing new specifications from interested partners for joint development of new applications. For detailed and personal discussions, colleagues from Fraunhofer FEP will be available during the 2nd OptecNet Annual Conference 2018 in Berlin, June 20-21, 2018.

2nd OptecNet Annual Conference

20–21 June 2018

Harnack Haus

Ihnestraße 16 – 20

14195 Berlin, Germany

http://optecnet.de/jahrestagung/jahrestagung-2018/

Staff from Fraunhofer FEP will be present at the exhibition booth.

Press contact:

Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP

Winterbergstraße 28 | 01277 Dresden, Germany | www.fep.fraunhofer.de

Head of Marketing: Ines Schedwill | Phone +49 351 8823-238 | ines.schedwill@fep.fraunhofer.de

Head of Corporate Communications: Annett Arnold, M.Sc. | Phone +49 351 2586-333 | annett.arnold@fep.fraunhofer.de

http://optecnet.de/jahrestagung/jahrestagung-2018/

http://s.fhg.de/6Ut

Media Contact

More Information:

http://www.fep.fraunhofer.de/All latest news from the category: Process Engineering

This special field revolves around processes for modifying material properties (milling, cooling), composition (filtration, distillation) and type (oxidation, hydration).

Valuable information is available on a broad range of technologies including material separation, laser processes, measuring techniques and robot engineering in addition to testing methods and coating and materials analysis processes.

Newest articles

Superradiant atoms could push the boundaries of how precisely time can be measured

Superradiant atoms can help us measure time more precisely than ever. In a new study, researchers from the University of Copenhagen present a new method for measuring the time interval,…

Ion thermoelectric conversion devices for near room temperature

The electrode sheet of the thermoelectric device consists of ionic hydrogel, which is sandwiched between the electrodes to form, and the Prussian blue on the electrode undergoes a redox reaction…

Zap Energy achieves 37-million-degree temperatures in a compact device

New publication reports record electron temperatures for a small-scale, sheared-flow-stabilized Z-pinch fusion device. In the nine decades since humans first produced fusion reactions, only a few fusion technologies have demonstrated…