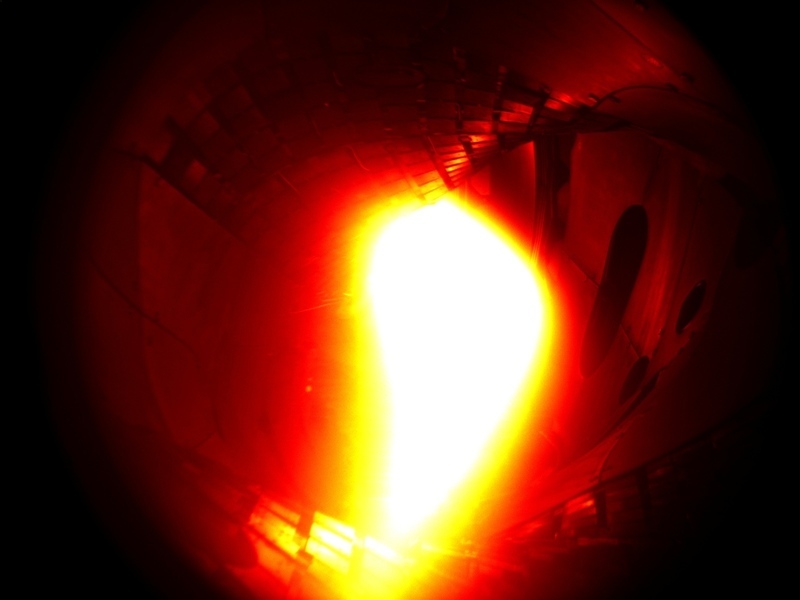

The first plasma in the Wendelstein 7-X fusion device in Greifswald presents itself with a bright glow. It consisted of helium and reached a temperature of about one million degrees Celsius.

© IPP

Known for its efficiency and stability in transmitting power, helium plasma is a prospective coolant for fusion reactors. It is considered the world’s largest fusion plant of the Stellarator type. Renewable energy sources not only preserve the environment but also reduce costs. In anticipation, the simulation of the nuclear fusion of hydrogen nuclei may play a crucial role as an eco-friendly energy source.

First Helium Plasma—Worth the Wait of 10 Years!

The plasma researchers’ efforts and patience have paid off. On December 10th, a good ten years after the assembly of the Wendelstein 7-X fusion device began at the Max Planck Institute for Plasma Physics (IPP) in Greifswald, physicists produced the first helium plasma.

After over a year of technical preparation and tests, experimental operation has now commenced according to plan. With the Wendelstein 7-X, the world’s largest stellarator-type fusion device, the researchers would like to prove that this type of device is suitable for use as a power station.

After a construction period of nine years and over one million assembly hours, the main construction work on the Wendelstein 7-X came to an end in April 2014. Preparation for the operation of the fusion device has been under way ever since.

Scientists and technicians tested all of its components in turn; the vacuum in the vessels, the cooling system, the superconducting coils and the magnetic field they produce, the control system, and the heating devices and measuring instruments.

The time had finally come on December 10th: the operating team in the control room started up the magnetic field, in which the plasma is confined so that it does not come into contact with the wall of the plasma chamber and cools down. The experiment’s computer-operated control system was then activated.

It fed around one milligram of helium gas into the plasma vessel, from which the air had already been evacuated. The team then switched on the microwave heating for a short 1.8-kilowatt pulse – and the first plasma could be observed by the installed cameras and measuring devices.

First hydrogen plasma to be produced by the end of January

“We’re starting with a plasma produced from the noble gas helium. We will not change over to the actual test object, a hydrogen plasma, until next year,” explains project leader Thomas Klinger, Director at Max Planck Institute for Plasma Physics (IPP) and head of the Wendelstein 7-X project. “This is because it’s easier to achieve the plasma state with helium. Moreover, we can clean the surface of the plasma vessel with helium plasmas,” he adds.

The first plasma in the machine lasted one tenth of a second and reached a temperature of around one million degrees. “We’re very satisfied,” says Hans-Stephan Bosch, whose division is responsible for the operation of the Wendelstein 7-X. “Everything went according to plan.”

In the next stages of the experiment, the researchers want to extend the duration of the plasma discharges and to investigate the best method for producing and heating helium plasmas using microwaves. After a break for New Year, confinement studies will resume in January when the scientist will test, among other things, how well the helium plasma is confined in the magnetic field. With these tests, the scientists will prepare the way for the first experiments with hydrogen plasma, which is ultimately intended to be fused into helium in the fusion experiments.

Background

The objective of fusion research is to develop a climate- and environmentally-friendly power plant, which, like the sun, harvests energy from the fusion of atomic nuclei. As the fusion fire only ignites at temperatures in excess of 100 million degrees, the fuel – a thin hydrogen plasma – must not come into contact with cold vessel walls. Confined by magnetic fields, it floats almost entirely contact-free in the interior of a vacuum chamber. Two different designs for the magnetic cage have become established – the tokamak and the stellarator. Both types of system are being tested at the IPP. The Tokamak ASDEX Upgrade is in operation in Garching and, as of today, the Wendelstein 7-X stellarator is operational in Greifswald.

Many scientists currently believe that a tokamak – the international test reactor ITER, which is currently being constructed in Cadarache as part of a worldwide collaborative project – is the only system capable of producing an energy-supplying plasma. The Wendelstein 7-X, the world’s largest stellarator-type fusion device, will not produce energy. Nevertheless, it should demonstrate that stellarators are also suitable for use as power plants. Using the Wendelstein 7-X it is intended to demonstrate for the first time that a stellarator can confine a plasma as well as a tokamak. And with discharges lasting 30 minutes, the stellarator should also demonstrate its crucial advantage – the ability to operate continuously. In contrast, without the help of complicated supplementary measures, tokamaks can only operate in pulses.

The assembly of Wendelstein 7-X began in April 2005: a ring of 50 superconducting coils, which are around 3.5 metres tall, forms the core of the device. The special shapes of the coils are the result of refined optimization calculations carried out by the IPP’s “Stellarator Theory” division, which spent over ten years searching for a magnetic cage that is particularly heat insulating. The coils are threaded onto a ring-shaped steel plasma vessel and encased by a steel shell. In the vacuum generated inside the shell, the coils are cooled down to superconduction temperature close to absolute zero using liquid helium. Once switched on, they consume hardly any energy. The magnetic cage they create keeps the 30 cubic metres of ultra-thin plasma – the test object – suspended inside the plasma vessel.

The investment costs of the Wendelstein 7-X total EUR 370 million and were provided by the German federal and federal state governments and the EU. The components were manufactured by companies throughout Europe. Orders in excess of EUR 70 million were placed with companies in the region. Numerous research facilities at home and abroad were involved in the construction of the device. As part of the Helmholtz Association of German Research Centres, the Karlsruhe Institute of Technology was responsible for the microwave plasma heating; the Forschungszentrum Jülich built measuring instruments and produced the complex connections for the superconducting magnetic coils. The installation was carried out by experts from the Polish Academy of Sciences in Krakow. The American fusion research institutes at Princeton, Oak Ridge and Los Alamos contributed equipment for the Wendelstein 7-X which included auxiliary coils and measuring instruments.

Contact

Prof. Dr. Thomas Klinger

Max Planck Institute for Plasma Physics, Garching

Phone: +49 3834 88-2501

Fax: +49 3834 88-2009

Email: thomas.klinger@ipp.mpg.de

Isabella Milch

Press Officer, Head of Public Relations, and Press Department

Max Planck Institute for Plasma Physics, Garching

Phone: +49 89 3299-1288

Fax: +49 89 3299-2622

Email: isabella.milch@ipp.mpg.de

Effective Renewable Energy Sources

According to the International Energy Agency (IEA), fossil fuel usage for electricity generation started to reduce from the year 2019. People were more interested in adopting renewable sources of energy to satisfy global energy demands. Hence, more researchers and scientists are focused on developing renewable energy (RE) technologies suitable for RE generation to foster energy conversion efficiency. Renewable energy technologies such as solar energy, wind energy, hydropower, tidal energy, bioenergy, geothermal energy, and hydrogen energy are employed to fuel power plants. In addition, several hybrid RE technologies have also been studied to enhance the overall performance of RE in electricity generation.

Powering towards a Renewable Future

The Wendelstein 7-X stellarator has remarkably contributed to fusion research by validating the potential of stellarator designs for sustained plasma confinement. On February 3, 2016, W7-X successfully transitioned from helium to hydrogen plasma, along with ongoing upgrades and experimental campaigns. This has emphasized its role in the further analysis of fusion energy. As fusion research progresses, W7-X’s findings will be an instrumental foundation for shaping the development of future fusion power plants.