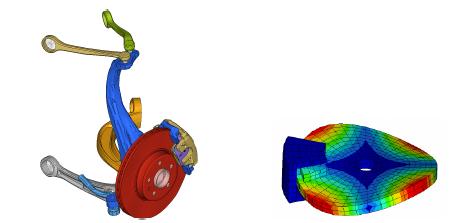

General view of FE car brake models

Mehrmann

Whether you are in your car or on the train, squealing brakes are an annoyance we all forced to live with – until now… “There is no reason to assume that noisy brakes are due to a defect in the brake system or to functional problems,” says Prof. Volker Mehrmann, a mathematician at the Technical University in Berlin and spokesperson for the research centre known as the MATHEON.

In collaboration with his working group, he has investigated the development of new methods to simulate squealing brakes as part of a research project and has developed and implemented new algorithms which, even if they cannot do away with the phenomenon entirely, make it easier to understand how they occur, thus offering brake manufacturers improved ways to optimise their products.

“Squealing occurs due to vibrations that are caused by rubbing on the brake and that draw attention to themselves as irritating noises,” explains the mathematician. He draws a comparison with a group of people marching in time over a bridge, thereby causing it to vibrate. In this case, however, the vibrations are visible to the human eye, while the vibrations that occur when braking produce an unpleasant squeal that is torture for the ears. The causes of this noise have been known for years.

It is also clear that the vibrations occur at different times as a result of dirt, the age of the brake and the quality of the material surface. However, the question of how to eliminate squealing remains unanswered. “We have collaborated with Professor Utz von Wagner of the Institute for Mechanics at the Technical University in Berlin in carrying out tests on commercial brakes, leading us to conclude that sometimes a short tap on the brakes with a screwdriver can be enough to cause the squeal, or even to bring it to a sudden end,” says the academic.

Professor Wagner was the actual initiator of the project. The Ministry for Economics suggested that he should form a consortium to solve this noise problem. On the user side, the consortium's members included two well-known car manufacturers, a software company for modelling software and several small and medium-sized manufacturers of brakes or brake parts.

However, it was clear from the start that it would not be possible to resolve the problem without mathematics. That's where Volker Mehrmann and his working group in the MATHEON came in. “The old methods used to calculate when brakes would squeal were not really very sophisticated,” explains the mathematician.

What happens in practice is that the design is constantly changed during the design phase while a brake is being manufactured, so that the squealing can be eliminated or at least rendered inaudible through testing. Different materials are used to experiment with changing the shape of the brake disc, as well as a number of other parameters. “It is possible to achieve reasonably good results in the laboratory. The problem is, however, that in reality the form and character of the brake disc are constantly changing.

Wear, dirt, weathering and lots more besides play a role here. That's why new brakes normally don't squeal,” says Volker Mehrmann, outlining the problem. Thus, the ideal conditions in the laboratory do not usually reflect reality. That's why one of the central questions of the project was whether it is possible to take some changes into account during the design phase.

That's where mathematics comes into play! “In order to take such parameters into account in this development phase, it is necessary to develop a mathematical model. Endless experiments would be far too protracted here. However, even in mathematical terms, this high-grade, non-linear problem cannot be resolved with standard solutions,” says Prof.

Mehrmann Such mathematical solutions are already used for industrial testing purposes. However, both the automobile industry and software companies tend to use very simplified models. When calculating reduced models used in optimisation, friction and damping are simply ignored. “Because many properties are omitted, this model works astonishingly well, but just not well enough,” admits Volker Mehrmann.

The team of mathematicians around Volker Mehrmann have therefore developed a new solution for calculating the natural vibrations of the brakes. This means that many more parameters can be tested in a small model. However, when testing this model under real conditions, it was found that the mathematical model was “very susceptible to malfunction”.

“The results were so poor that we were sceptical. Finally we discovered – almost by chance – that there is a trick generally used with rigid connections in mechanical engineering whereby an extremely rigid spring is incorporated in the already rigid connection for modelling purposes. This means that we are no longer faced with a rigid connection, which would have been unproblematic in mathematics. However, these “artificial” springs not only influenced our entire calculations, but often actually destroyed them. Our numeric simulation was unable to produce a useful result, particularly because these tricks vary from manufacturer to manufacturer,” says the mathematician.

Thus, the mathematicians had to modify the calculation models so that it was evident from the model whether this actually non-existent spring was used and what its effect was. “In terms of simplified modelling, we have actually made the model worse, however in terms of the numerical process we have improved it significantly. That's because we can now recognise whether these virtual springs have been installed and can replace them in our model with the realistic rigid connection. This makes the system significantly less sensitive and we can prove that the classic method used in industry sometimes leads to completely incorrect results,” explains the professor, describing subsequent procedures.

This has given rise to new software that includes these sensitivity checks. However, this has still not solved the real problem facing brake manufacturers. If you assume that the “new” model is really correct, you may get usable results, but is it still not proven that the model is really good. Thus, there is still the danger that poor results will be achieved. “For us mathematicians this is the reason why we believe, despite this significant improvement, that it is necessary to change our entire approach and to try to resolve the problem with non-linear modelling,” believes Volker Mehrmann. However, he is doubtful whether this can be implemented by the manufacturers at present. Such a complex mathematical problem can probably only be satisfactorily resolved in a research institute such as the MATHEON. Volker Mehrmann and Utz von Wagner have therefore already applied to the German Research Foundation for support in producing a fundamentally new model and analysis.

Another very decisive new step has also been successful as part of investigations in the MATHEON Research Centre. By considering the brake as a so-called port-Hamiltonian model, the model reduction is simplified and the investigation of the phenomena that generate the squealing are significantly reduced in terms of the calculation effort required. The port-Hamiltonian formulation ensures that the mathematical description adhere much more closely to the real physics of the problem and allows a much simpler stability analysis. The theoretical bases for this were drawn up on a recently completed research study and are now to be implemented in numeric methods and software.

The current result of the recently completed project is thus that the software companies and car manufacturers have now gained significantly better software that they can use to calculate their models. They have also been given a method that will enable them to determine very quickly when their calculations are unusable and they now have a model reduction method for generating a very small model and thus a general opportunity to significantly improve their software. Thus, the mathematicians have provided brake manufacturers and car makers with better tools for improving brake design.

Another significant success for Volker Mehrmann work group at the MATHEON Research Centre is the recognition that a general change is needed to the methods used for applied quadratic eigenvalue problems in relation to the issue of noise reduction. A new theory developed in an earlier MATHEON project in relation to the question of vibrations and noise generation on railway lines has given rise to a much-cited mathematical paper that promises huge successes in solving the problem of squealing brakes.

“In the final analysis I am convinced that none of this is anything like enough and that we shall have to go one step further with the mathematical methods. Only then will it be possible to shift the squeal into the non-audible range. It will certainly never be possible to eliminate it entirely except with a highly developed, and therefore very expensive, sensor-based solution,” summarises Prof. Volker Mehrmann.

http://www.matheon.de

http://www.math.tu-berlin.de/fachgebiete_ag_modnumdiff/fg_numerische_mathematik/…