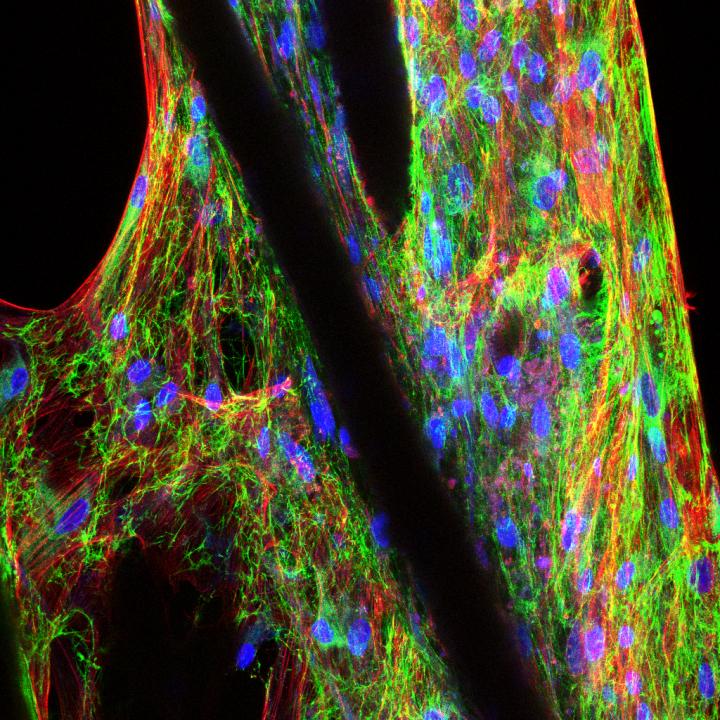

Confocal laser microscopy of a scaffold populated with human mesenchymal precursor cells.

Credit: D. Hutmacher / QUT

An international study published in the journal Nature Communications points the way toward wider, more effective use of biocompatible materials in repairing human tissues. Focusing on the difficult case of restoring cartilage, which requires both flexibility and mechanical strength, the researchers investigated a new combination of 3-D printed microfiber scaffolding and hydrogels. The composites they tested showed elasticity and stiffness comparable to knee-joint tissue, as well as the ability to support the growth and cross-linking of human cartilage cells. Researchers at the Technische Universität München (TUM) expect the new approach to have an impact on other areas of soft-tissue engineering research, including breast reconstruction and heart tissue engineering.

A new 3-D printing technique called melt electrospinning writing played a key role, simultaneously providing room for cell growth as well as the needed mechanical stiffness. This method offers much more freedom in the design of scaffolding to promote healing and growth of new tissue, explains Prof. Dietmar W. Hutmacher, one of the lead authors. “It allows us to more closely imitate nature's way of building joint cartilage,” he says, “which means reinforcing a soft gel – proteoglycans or, in our case, a biocompatible hydrogel – with a network of very thin fibers.” Scaffolding filaments produced by melt electrospinning writing can be as thin as five micrometers in diameter, a 20-fold improvement over conventional methods.

Based at the Queensland University of Technology in Australia, Prof. Hutmacher is a Hans Fischer Senior Fellow of the TUM Institute for Advanced Study. His TUM-IAS Focus Group on Regenerative Medicine is hosted by TUM Prof. Arndt Schilling, head of the Research Dept. of Plastic Surgery and Hand Surgery at TUM's university hospital Klinikum rechts der Isar.

Multi-pronged study of a versatile technology

The collaborators – working in Australia, Germany, the Netherlands, and the UK – brought a wide range of research tools to bear on this investigation. Efforts focusing on the design, fabrication, and mechanical testing of hydrogel-fiber composites were complemented by comparisons with equine knee-joint cartilage, experiments with the growth of human cartilage cells in the artificial matrix, and computational simulations.

All the evidence points in the direction of what Hutmacher calls, cautiously, a breakthrough. Having validated the computer model of their hydrogel-fiber composites, the researchers are using it to assess a variety of potential applications. “The new approach looks promising not only for joint repair, but also for uses such as breast reconstruction following a post-tumor mastectomy or heart tissue engineering,” Prof. Hutmacher says. “We need to implant the scaffolding under the muscle, and fiber-reinforced hydrogel could prove critical in regenerating large volumes of breast tissue, as well as the biomechanically highly loaded heart valves.”

Prof. Hutmacher and his collaborators at TUM – Prof. Arndt Schilling, PD. Dr. Jan-Thorsten Schantz, and Dr. Elizabeth Balmayor – already plan to use the approach described in the Nature Communications paper for their breast tissue engineering research They also have begun a project, in collaboration with the group of Prof. Stefan Jockenhövel and Dr. Petula Mela at the RWTH Aachen, on engineering heart valve tissue.

###

This research has been supported by grants from the European Commission (PIOF-GA-282286, the European Union's FP7 (n309962 – HydroZONES), the Dutch government (NIRM, grant nFES0908), the Dutch Arthritis Foundation, the Australian National Health and Medical Research Council. The TUM-IAS receives support from the German Excellence Initiative and the EU's FP7 (Marie Curie COFUND).

Contact

Prof. Dietmar W. Hutmacher

Technische Universität München

TUM Institute for Advanced Study

E: dietmar.hutmacher@qut.edu.au

W: http://www.

Publication

Reinforcement of hydrogels using three-dimensionally printed microfibres. Jetze Visser, Ferry P.W. Melchels, June E. Jeon, Erik M. van Bussel, Laura S. Kimpton, Helen M. Byrne, Wouter J. A. Dhert, Paul D. Dalton, Dietmar W. Hutmacher, and Jos Malda. Nature Communications, 28 April 2015. DOI: 10.1038/ncomms7933.

Technische Universität München (TUM) is one of Europe's leading research universities, with around 500 professors, 10,000 academic and non-academic staff, and more than 37,000 students. Its focus areas are the engineering sciences, natural sciences, life sciences and medicine, reinforced by schools of management and education. TUM acts as an entrepreneurial university that promotes talents and creates value for society. In that it profits from having strong partners in science and industry. It is represented worldwide with a campus in Singapore as well as offices in Beijing, Brussels, Cairo, Mumbai, and São Paulo. Nobel Prize winners and inventors such as Rudolf Diesel and Carl von Linde have done research at TUM. In 2006 and 2012 it won recognition as a German “Excellence University.” In international rankings, TUM regularly places among the best universities in Germany.