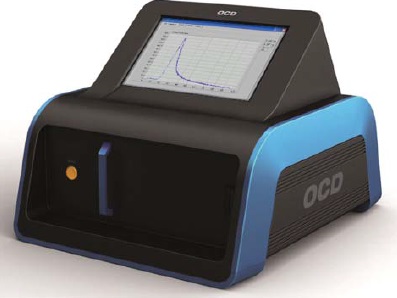

In just one and a half minutes, this prototype of a diagnostic device determines whether the prostate tissue sample is benign or malignant. © Fraunhofer IKTS

A new device facilitates the diagnosis for doctors: Through a visual analysis, they can reliably determine if they are dealing with carcinoma within a minuteand-a-half. Fraunhofer researchers will be presenting the prototype at the COMPAMED trade fair in Düsseldorf from November 12th to 14th.

Is it carcinoma of the prostate – or a benign tissue change?

To find this out, doctors take a biopsy of prostate tissue from the patient. In doing so, they insert a small needle into the prostate, using ultrasound images to assist with navigation. From the sample taken in this way, laboratory employees fabricate wafer-thin tissue sections – a laborious job that takes at least a day. Then, the tissue sections are forwarded to a pathologist, who examines them under the microscope. Even for experienced physicians, though, it is often diffi cult to distinguish between benign and malignant tissue.

Analysis at your fingertips

In the future, this research will be easier, faster and more precise − with an optical diagnostic device that researchers have developed at the Fraunhofer Institute for Ceramic Technologies and Systems IKTS in Dresden. A prototype is currently available. “The physician places the removed tissue sample on a base plate, slides it into the machine, presses a button – and within one and a half minutes, receives a reliable indication of whether the tissue in the sample is benign or malignant,” describes Dr. Jörg Opitz, scientist at IKTS.

Since the sample does not require a long preparation time and can be pushed directly into the device and analyzed after it has been taken, the patient does not have to wait for days after the biopsy in order to know the outcome. The doctor receives the results immediately and can talk with the patient much sooner about the next steps to take.

Light stimulates the body’s own fluorescence

A further advantage is the reliability of the examinations. “The analyses are based on the auto-fl uorescence that human tissue emits”, says Opitz. There are fluorophores in every human body. These molecules are illuminated for a very short time when certain light falls on them. If the doctor sets the removed tissue in the device, starts the measurement, emits a dosage of laser pulse and excites the fl uorophores, then the laser pulse stimulates the fl uorescent molecules in the tissue to release light.

The way in which this fluorescence radiation decreases differs between benign and malignant tissue. The scientists have been able to determine a clear threshold for this different behavior: If the value of the tissue sample exceeds the threshold value, carcinoma is present. Thus, the doctors obtain a clear and unambiguous prognosis. The analysis proceeds automatically. The device shows the physician if the collected sample contains cancer tissue like the colors of a traffic signal.

Each tissue has its own threshold

Currently, the device can only be used for prostate cancer, since the threshold value of the unit only applies to this tissue. Each tissue type has a fi xed value, but they are different. Prostate tissue has a different value than does tissue from the chest or oral cavity. The researchers’ goal is to determine the threshold values for other tissue types and to integrate them into the analysis software of the device. Then, the doctors will be able to examine different samples with the device: They would only need to enter the appropriate tissue type from a drop-down menu.

The optical diagnostic device has already completed its first two clinical studies, and the third study is currently underway. The scientists will be presenting the 53 x 60 x 43 centimeter prototype at the COMPAMED trade fair in Düsseldorf from November 12 to 14 (Hall 8a, Booth K38).

Contact

Dr. rer. nat. Jörg Opitz

Fraunhofer Institute for Ceramic Technologies and Systems, Branch Materials Diagnostics IKTS-MD

Phone +49 351 88815-516

joerg.opitz@ikts.fraunhofer.de