Researchers use flowing fluids to create mechanical stress needed for bone formation

A new study by Rice University researchers indicates that bioengineers growing bone in the laboratory may be able to create the mechanical stimulation needed to grow bone outside the body.

One of the greatest challenges tissue engineers face in growing bone in the laboratory is recreating the conditions that occur inside the body. The recipe for growing healthy bones includes not only a precise biological mix — bone cells called “osteoblasts” and several growth factors that osteoblasts use to build the mineralized matrix of bones — but also mechanical stimulation. Astronauts whose bones become brittle after months in orbit are a testament to the importance that mechanical stress plays in bone growth. In orbit, their skeletons aren’t subject to the everyday stresses of gravity.

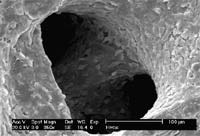

Tissue engineers at Rice placed bone marrow-derived osteoblasts from rats into centimeter-wide plexiglass chambers containing a thin stack of titanium fiber mesh. The samples were covered with a liquid growth medium — a bath of chemicals that promotes bone growth — and sealed in an incubator. After letting the cultures sit overnight — to give the cells time to attach themselves to the mesh — engineers pumped growth medium through the cultures for 16 days. Bone cultures were subjected to a range of three different flow rates to provide mechanical stimulation, and another set of cultures were grown in a motionless bath.

Results of the research appear in the current issue of the Proceedings of the National Academy of Sciences USA.

“Researchers have used fluid flow to stimulate bone growth before, but no one has looked at its effect on three-dimensional cultures that have been subjected to continuous stimulation for several days,” said Tony Mikos, the John W. Cox Professor of Bioengineering. “We found that even the lowest flow rate produced a significant increase in the formation of mineralized bone. Moreover, the mineralized bone that formed in samples subjected to flow was thick and well-developed — similar to what we find in natural bone –while the bone matrix formed by the static samples was thin and brittle.”

Mikos said more studies are needed to determine the exact flow rate needed to produce the optimal amount of bone matrix with the optimal three-dimensional structure. For those who have lost a segment of bone to cancer or injury, the technology isn’t expected to result in clinical treatment options for several years. Ultimately, however, artificial bone could be substituted for donor tissue or surgical implants made of synthetic materials.

The research was sponsored by the National Institutes of Health and NASA.

The article, titled “Fluid Flow Increases Mineralized Matrix Deposition in 3D Perfusion Culture of Marrow Stromal Osteoblasts in a Dose-Dependent Manner,” by G.N. Bancroft, V.I. Sikavitsas, J. van den Dolder, T.L. Sheffield, C.G. Ambrose, J.A. Jansen, and A.G. Mikos, appears in the Oct. 1 issue of Proceedings of the National Academy of Sciences