New flame retardant enters market

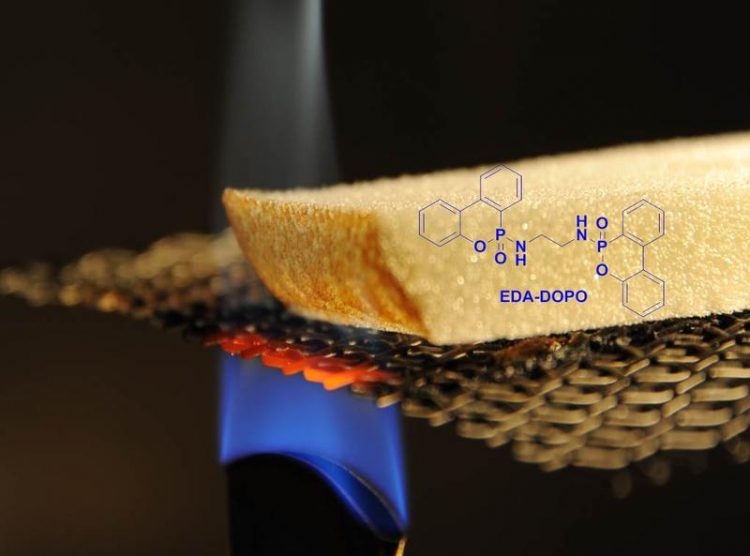

Foam sample with EDA-DOPO in a flame test in the Empa laboratory. Empa

EDA-DOPO, the environmentally friendly flame retardant developed at Empa, is going into serial production. The newly developed, particularly economic and ecological synthesis method, which also simplifies the production of other DOPO derivatives, is a crucial part of this success story.

The company Metadynea Austria GmbH will manufacture the material and, if there is sufficient demand, the global FoamPartner Group will use it to produce flame-retardant polyurethane (PU) foams for upholstery and mattresses. Since the new method of production of DOPO derivatives was patented in June 2017, Metadynea Austria GmbH has already produced around 1.5 tons of the flame retardant.

Non-Toxic

This constitutes the first step towards replacing conventional, halogenated flame retardants, which are sometime toxic and give off toxic gases in the event of a fire. Empa’s EDA-DOPO – a derivative of the familiar flame retardant DOPO (9,10-dihydro-10-oxa-phosphaphenanthreneoxide) – does not emit these toxins. Furthermore, the foam material containing this flame retardant satisfies the highest flame retardant classification (UL 94 HB).

Fire retardant expert Sabyasachi Gaan developed EDA-DOPO at Empa in a two-year research project within the scope of the Eureka SUSPUR project (www.eurekanetwork.org/project/id/8058). It was initiated by the FoamPartner Group, which was looking to expand its range with environmentally friendly flame retardant PU foams. The company is currently the sole license holder for EDA-DOPO for PU applications. The substance is manufactured exclusively by Metadynea Austria GmbH.

Mandatory for public areas

Flame-retardant upholstery is especially mandatory for areas where many people gather: Planes, trains, buses, hotels and restaurants. Flame retardants prevent materials from being ignited, such as with cigarettes or by vandals. However, the environmental standards keep getting stringent here, too. The evaporation of flame retardants into the ambient air or atmosphere is undesirable and the toxic gases that can form during a fire are also being accepted less and less. Many countries have already banned halogenated flame retardants. Consequently, there is a growing need for modern, harmless alternatives all over the world.

Although foam production with the new flame retardant is already underway, products containing EDA-DOPO will not be on sale just yet; the flame retardant is currently being certified in accordance with the European chemical regulation REACH. The foam samples produced are presently undergoing diverse flame tests to enable the new flame-retardant foams to hit the global markets as quickly as possible once they obtain their REACH certification.

Info box: Why do we need flame retardants?

We encounter PU foams in many places in everyday life: They are in the insulation on house façades, fridges, car seats, living room sofas and shoe soles. PU is composed of carbon, hydrogen, nitrogen and oxygen atoms. The air trapped in the foam’s pores also contains oxygen. Therefore, the foam – like most organic polymers – is highly flammable and, depending on the requirements, needs to be equipped with flame retardants to curb the risk of fire. In recent decades, foam manufacturers tended to use chlorinated phosphates as flame retardants – low-priced substances that do not disrupt the production process.

However, many of these chlorinated flame retardants are toxic and can eventually evaporate from the foam and get into the ambient air. As a result, these substances are already banned in many countries. Industry is thus on the lookout for environmentally friendly, harmless alternatives. And it’s big business: Every year, around 20 million tons of PU foam are produced worldwide, the majority of which is supposed to be equipped with flame retardants.

EDA-DOPO satisfies economic and ecological criteria with flying colors and has achieved the highest flame retardant classification UL 94 HB. The flame retardant is also highly compatible with the production process for PU foams: It mixes well with polyol, a base material of PU foam, and forms a stable dispersion. The production process results in a foam with the solid flame retardant EDA-DOPO finely distributed in its pores.

Media Contact

All latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

Combatting disruptive ‘noise’ in quantum communication

In a significant milestone for quantum communication technology, an experiment has demonstrated how networks can be leveraged to combat disruptive ‘noise’ in quantum communications. The international effort led by researchers…

Stretchable quantum dot display

Intrinsically stretchable quantum dot-based light-emitting diodes achieved record-breaking performance. A team of South Korean scientists led by Professor KIM Dae-Hyeong of the Center for Nanoparticle Research within the Institute for…

Internet can achieve quantum speed with light saved as sound

Researchers at the University of Copenhagen’s Niels Bohr Institute have developed a new way to create quantum memory: A small drum can store data sent with light in its sonic…