Injectable 3D vaccines could fight cancer and infectious diseases

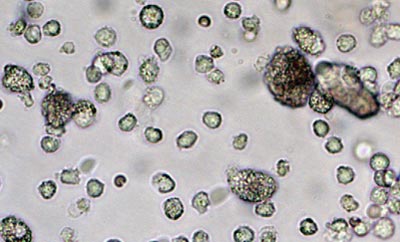

A microscope image shows many of the immune system's dendritic cells that were collected from a 3D scaffold three days after in vivo injection. The 3D scaffold effectively recruits and activates the dendritic cells to trigger an immune response against specific cells, such as cancerous cells. Credit: Wyss Institute at Harvard University

One of the reasons cancer is so deadly is that it can evade attack from the body's immune system, which allows tumors to flourish and spread. Scientists can try to induce the immune system, known as immunotherapy, to go into attack mode to fight cancer and to build long lasting immune resistance to cancer cells.

Now, researchers at the Wyss Institute for Biologically Inspired Engineering at Harvard University and Harvard's School of Engineering and Applied Sciences (SEAS) show a non–surgical injection of programmable biomaterial that spontaneously assembles in vivo into a 3D structure could fight and even help prevent cancer and also infectious disease such as HIV. Their findings are reported in Nature Biotechnology.

“We can create 3D structures using minimally–invasive delivery to enrich and activate a host's immune cells to target and attack harmful cells in vivo,” said the study's senior author David Mooney, Ph.D., who is a Wyss Institute Core Faculty member and the Robert P. Pinkas Professor of Bioengineering at Harvard SEAS.

Tiny biodegradable rod–like structures made from silica, known as mesoporous silica rods (MSRs), can be loaded with biological and chemical drug components and then delivered by needle just underneath the skin. The rods spontaneously assemble at the vaccination site to form a three–dimensional scaffold, like pouring a box of matchsticks into a pile on a table. The porous spaces in the stack of MSRs are large enough to recruit and fill up with dendritic cells, which are “surveillance” cells that monitor the body and trigger an immune response when a harmful presence is detected.

“Nano–sized mesoporous silica particles have already been established as useful for manipulating individual cells from the inside, but this is the first time that larger particles, in the micron–sized range, are used to create a 3D in vivo scaffold that can recruit and attract tens of millions of immune cells,” said co-lead author Jaeyun Kim, Ph.D., an Assistant Professor of Chemical Engineering at Sungkyunkwan University and a former Wyss Institute Postdoctoral Fellow.

Synthesized in the lab, the MSRs are built with small holes, known as nanopores, inside. The nanopores can be filled with specific cytokines, oligonucleotides, large protein antigens, or any variety of drugs of interest to allow a vast number of possible combinations to treat a range of infections.

“Although right now we are focusing on developing a cancer vaccine, in the future we could be able to manipulate which type of dendritic cells or other types of immune cells are recruited to the 3D scaffold by using different kinds of cytokines released from the MSRs,” said co-lead author Aileen Li, a graduate student pursuing her Ph.D. in bioengineering at Harvard SEAS. “By tuning the surface properties and pore size of the MSRs, and therefore controlling the introduction and release of various proteins and drugs, we can manipulate the immune system to treat multiple diseases.”

Once the 3D scaffold has recruited dendritic cells from the body, the drugs contained in the MSRs are released, which trips their “surveillance” trigger and initiates an immune response. The activated dendritic cells leave the scaffold and travel to the lymph nodes, where they raise alarm and direct the body's immune system to attack specific cells, such as cancerous cells. At the site of the injection, the MSRs biodegrade and dissolve naturally within a few months.

So far, the researchers have only tested the 3D vaccine in mice, but have found that it is highly effective. An experiment showed that the injectable 3D scaffold recruited and attracted millions of dendritic cells in a host mouse, before dispersing the cells to the lymph nodes and triggering a powerful immune response.

The vaccines are easily and rapidly manufactured so that they could potentially be widely available very quickly in the face of an emerging infectious disease. “We anticipate 3D vaccines could be broadly useful for many settings, and their injectable nature would also make them easy to administer both inside and outside a clinic,” said Mooney.

Since the vaccine works by triggering an immune response, the method could even be used preventatively by building the body's immune resistance prior to infection.

“Injectable immunotherapies that use programmable biomaterials as a powerful vehicle to deliver targeted treatment and preventative care could help fight a whole range of deadly infections, including common worldwide killers like HIV and Ebola, as well as cancer,” said Wyss Institute Founding Director Donald Ingber, M.D., Ph.D. who is also Judah Folkman Professor of Vascular Biology at Harvard Medical School and Boston Children's Hospital, and Professor of Bioengineering at Harvard SEAS. “These injectable 3D vaccines offer a minimally invasive and scalable way to deliver therapies that work by mimicking the body’s own powerful immune–response in diseases that have previously been able to skirt immune detection.”

Additional co-authors included Youngjin Choi of Sungkyunkwan University in Korea, Sarah A. Lewin of the Wyss Institute, Catia S. Verbeke of Harvard SEAS and the Wyss Institute, and Glenn Dranoff of the Dana-Farber Cancer Institute and Harvard Medical School.

The research was supported by the National Institutes of Health (1R01EB015498), the National Science Foundation, the Wyss Institute for Biologically Inspired Engineering at Harvard University, and the National Research Foundation of Korea.

PRESS CONTACTS

Wyss Institute for Biologically Inspired Engineering at Harvard University

Kat J. McAlpine, katherine.mcalpine@wyss.harvard.edu, +1 617-432-8266

Harvard School of Engineering and Applied Sciences

Caroline Perry, cperry@seas.harvard.edu, +1 617-496-1351

IMAGES AVAILABLE

The Wyss Institute for Biologically Inspired Engineering at Harvard University (http://wyss.harvard.edu) uses Nature's design principles to develop bioinspired materials and devices that will transform medicine and create a more sustainable world. Working as an alliance among all of Harvard's Schools, and in partnership with Beth Israel Deaconess Medical Center, Brigham and Women's Hospital, Boston Children's Hospital, Dana–Farber Cancer Institute, Massachusetts General Hospital, the University of Massachusetts Medical School, Spaulding Rehabilitation Hospital, Boston University, Tufts University, and Charité – Universitätsmedizin Berlin, University of Zurich and Massachusetts Institute of Technology, the Institute crosses disciplinary and institutional barriers to engage in high-risk research that leads to transformative technological breakthroughs. By emulating Nature's principles for self-organizing and self-regulating, Wyss researchers are developing innovative new engineering solutions for healthcare, energy, architecture, robotics, and manufacturing. These technologies are translated into commercial products and therapies through collaborations with clinical investigators, corporate alliances, and new start-ups.

The Harvard School of Engineering and Applied Sciences (SEAS) serves as the connector and integrator of Harvard's teaching and research efforts in engineering, applied sciences, and technology. Through collaboration with researchers from all parts of Harvard, other universities, and corporate and foundational partners, we bring discovery and innovation directly to bear on improving human life and society.

For more information, visit: http://seas.harvard.edu

Media Contact

More Information:

http://wyss.harvard.edu/viewpressrelease/183/All latest news from the category: Life Sciences and Chemistry

Articles and reports from the Life Sciences and chemistry area deal with applied and basic research into modern biology, chemistry and human medicine.

Valuable information can be found on a range of life sciences fields including bacteriology, biochemistry, bionics, bioinformatics, biophysics, biotechnology, genetics, geobotany, human biology, marine biology, microbiology, molecular biology, cellular biology, zoology, bioinorganic chemistry, microchemistry and environmental chemistry.

Newest articles

Bringing bio-inspired robots to life

Nebraska researcher Eric Markvicka gets NSF CAREER Award to pursue manufacture of novel materials for soft robotics and stretchable electronics. Engineers are increasingly eager to develop robots that mimic the…

Bella moths use poison to attract mates

Scientists are closer to finding out how. Pyrrolizidine alkaloids are as bitter and toxic as they are hard to pronounce. They’re produced by several different types of plants and are…

AI tool creates ‘synthetic’ images of cells

…for enhanced microscopy analysis. Observing individual cells through microscopes can reveal a range of important cell biological phenomena that frequently play a role in human diseases, but the process of…